| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679322 | CIRP Annals - Manufacturing Technology | 2014 | 4 Pages |

Abstract

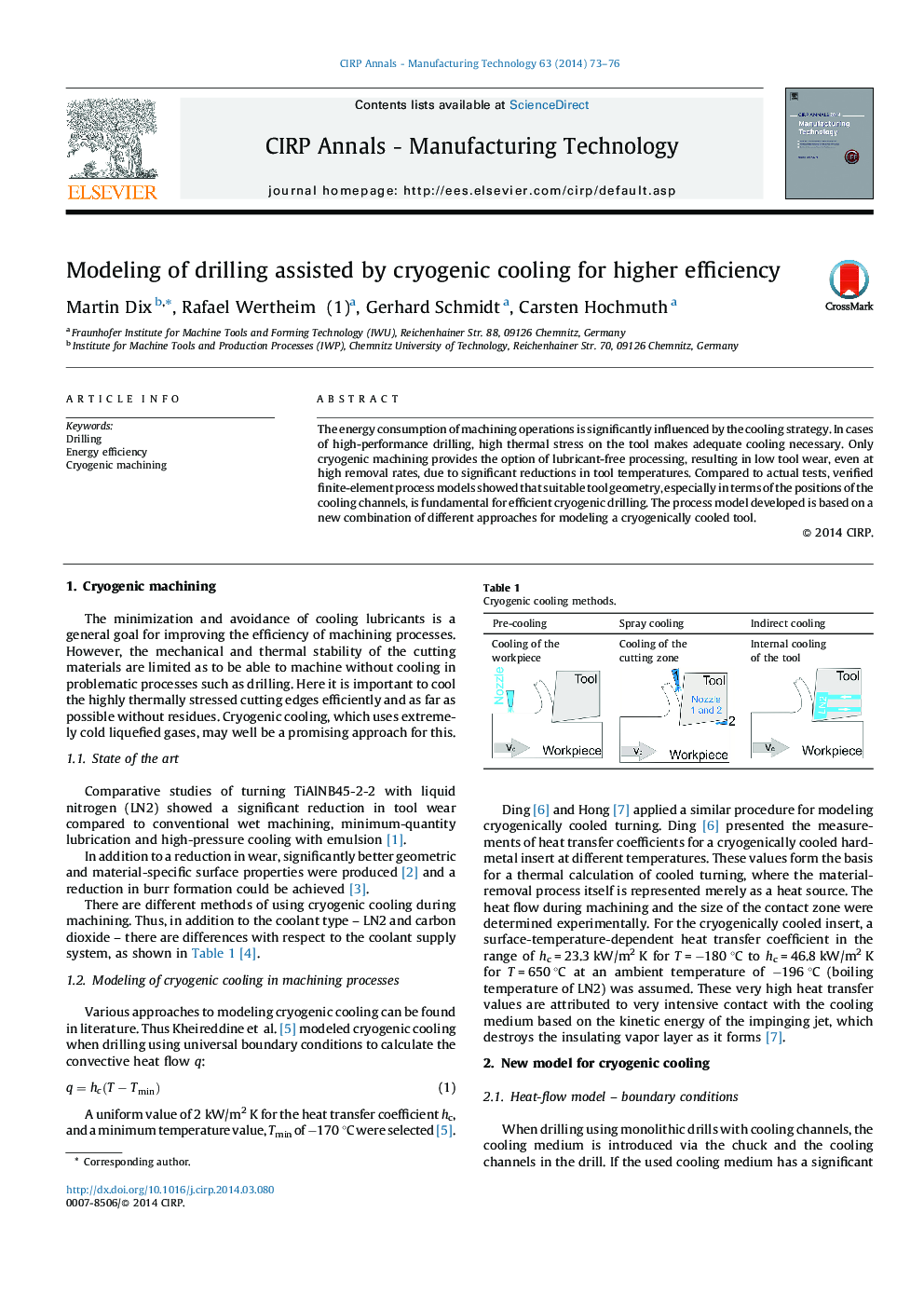

The energy consumption of machining operations is significantly influenced by the cooling strategy. In cases of high-performance drilling, high thermal stress on the tool makes adequate cooling necessary. Only cryogenic machining provides the option of lubricant-free processing, resulting in low tool wear, even at high removal rates, due to significant reductions in tool temperatures. Compared to actual tests, verified finite-element process models showed that suitable tool geometry, especially in terms of the positions of the cooling channels, is fundamental for efficient cryogenic drilling. The process model developed is based on a new combination of different approaches for modeling a cryogenically cooled tool.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Martin Dix, Rafael Wertheim, Gerhard Schmidt, Carsten Hochmuth,