| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679325 | CIRP Annals - Manufacturing Technology | 2014 | 4 Pages |

Abstract

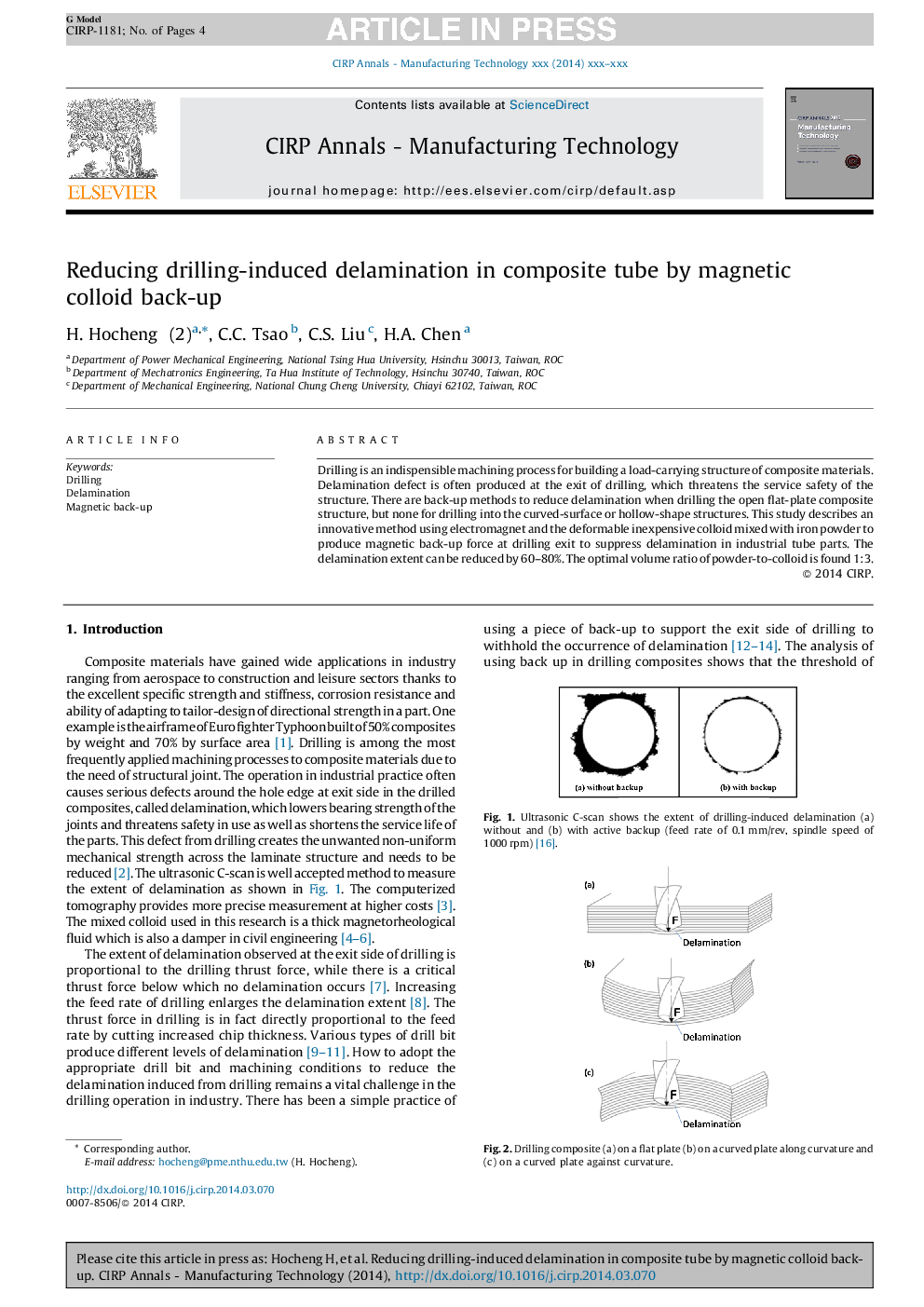

Drilling is an indispensible machining process for building a load-carrying structure of composite materials. Delamination defect is often produced at the exit of drilling, which threatens the service safety of the structure. There are back-up methods to reduce delamination when drilling the open flat-plate composite structure, but none for drilling into the curved-surface or hollow-shape structures. This study describes an innovative method using electromagnet and the deformable inexpensive colloid mixed with iron powder to produce magnetic back-up force at drilling exit to suppress delamination in industrial tube parts. The delamination extent can be reduced by 60-80%. The optimal volume ratio of powder-to-colloid is found 1:3.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

H. Hocheng, C.C. Tsao, C.S. Liu, H.A. Chen,