| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679335 | CIRP Annals - Manufacturing Technology | 2014 | 4 Pages |

Abstract

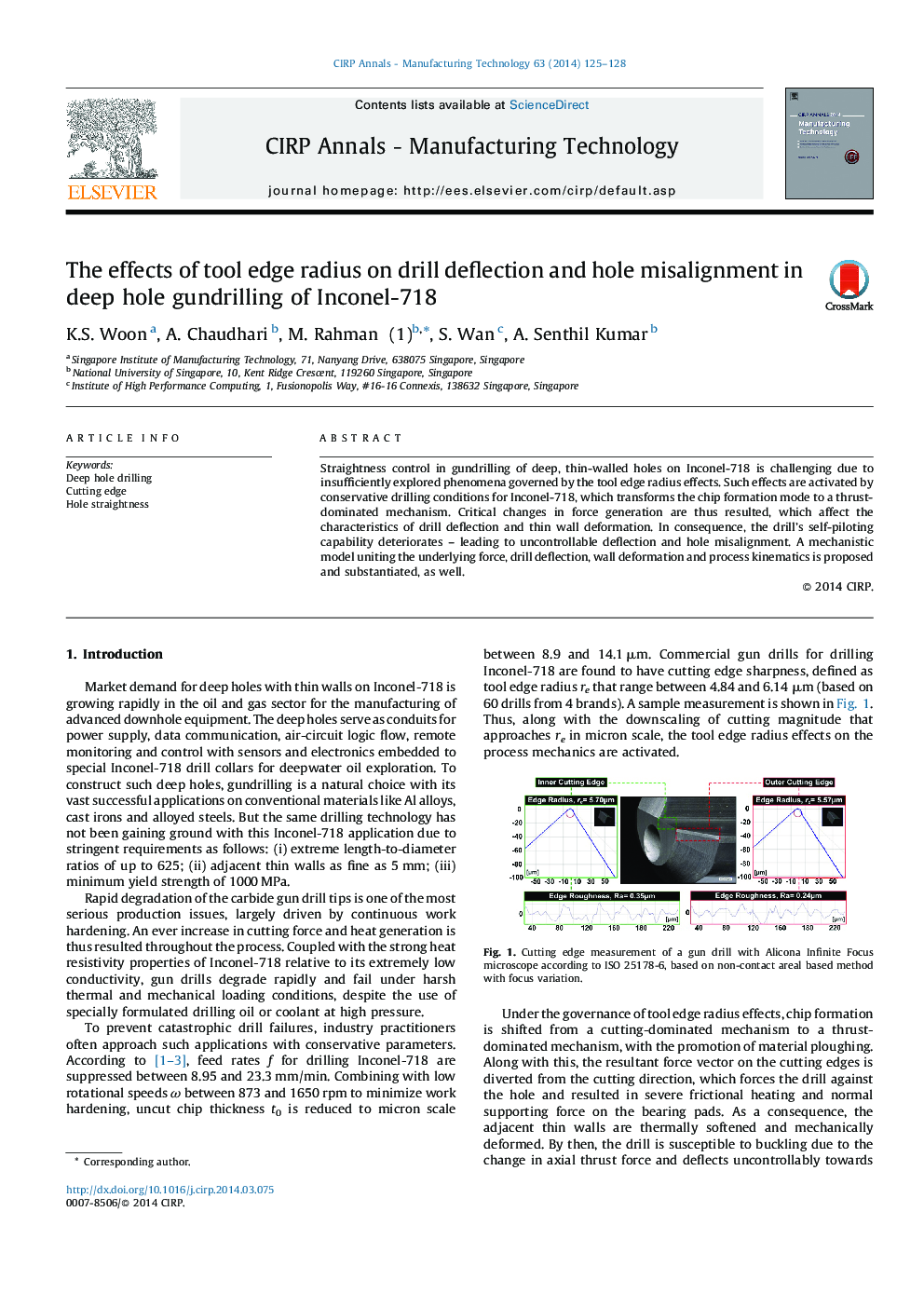

Straightness control in gundrilling of deep, thin-walled holes on Inconel-718 is challenging due to insufficiently explored phenomena governed by the tool edge radius effects. Such effects are activated by conservative drilling conditions for Inconel-718, which transforms the chip formation mode to a thrust-dominated mechanism. Critical changes in force generation are thus resulted, which affect the characteristics of drill deflection and thin wall deformation. In consequence, the drill's self-piloting capability deteriorates – leading to uncontrollable deflection and hole misalignment. A mechanistic model uniting the underlying force, drill deflection, wall deformation and process kinematics is proposed and substantiated, as well.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

K.S. Woon, A. Chaudhari, M. Rahman, S. Wan, A. Senthil Kumar,