| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679387 | CIRP Annals - Manufacturing Technology | 2014 | 4 Pages |

Abstract

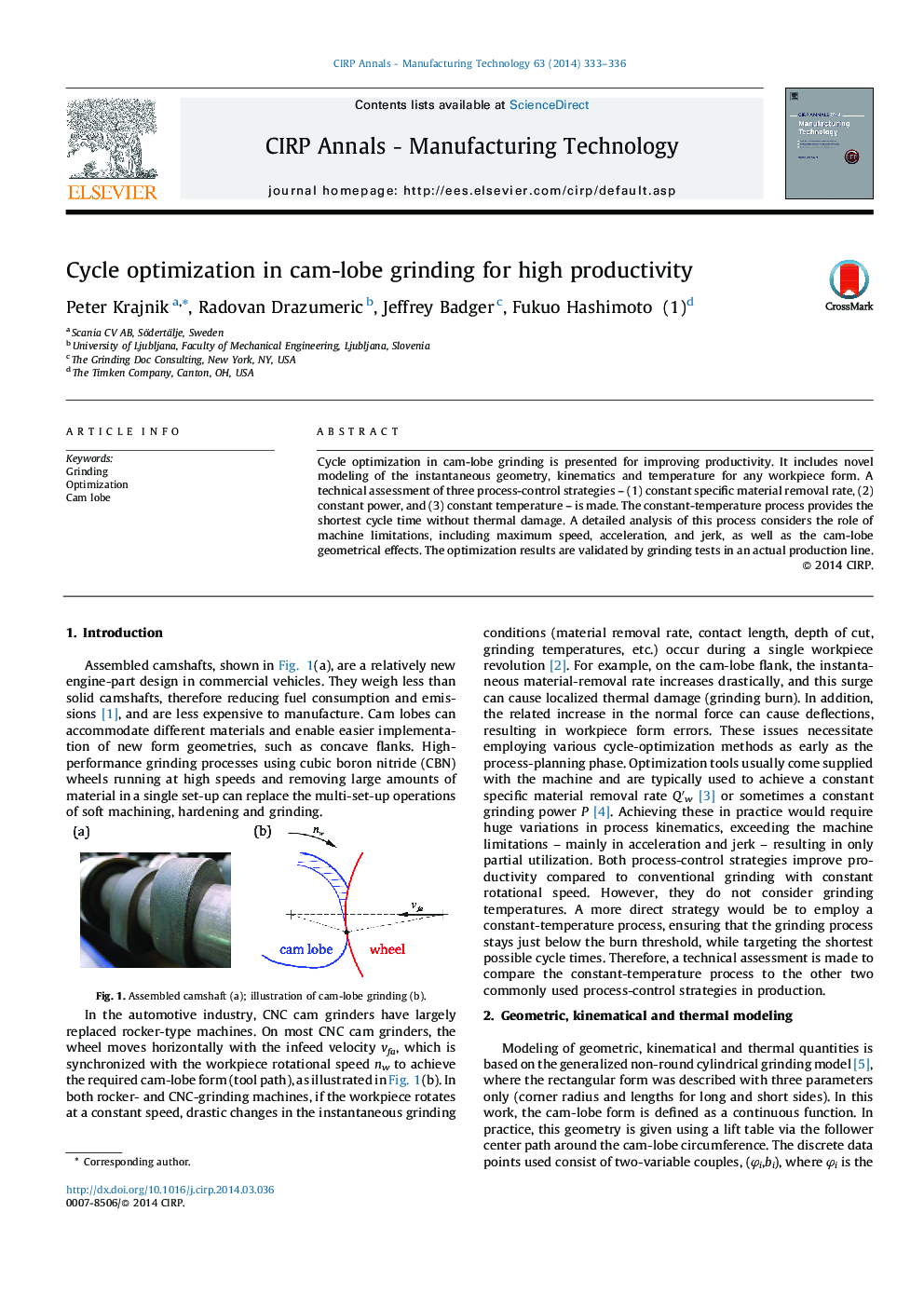

Cycle optimization in cam-lobe grinding is presented for improving productivity. It includes novel modeling of the instantaneous geometry, kinematics and temperature for any workpiece form. A technical assessment of three process-control strategies – (1) constant specific material removal rate, (2) constant power, and (3) constant temperature – is made. The constant-temperature process provides the shortest cycle time without thermal damage. A detailed analysis of this process considers the role of machine limitations, including maximum speed, acceleration, and jerk, as well as the cam-lobe geometrical effects. The optimization results are validated by grinding tests in an actual production line.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Peter Krajnik, Radovan Drazumeric, Jeffrey Badger, Fukuo Hashimoto,