| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679576 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

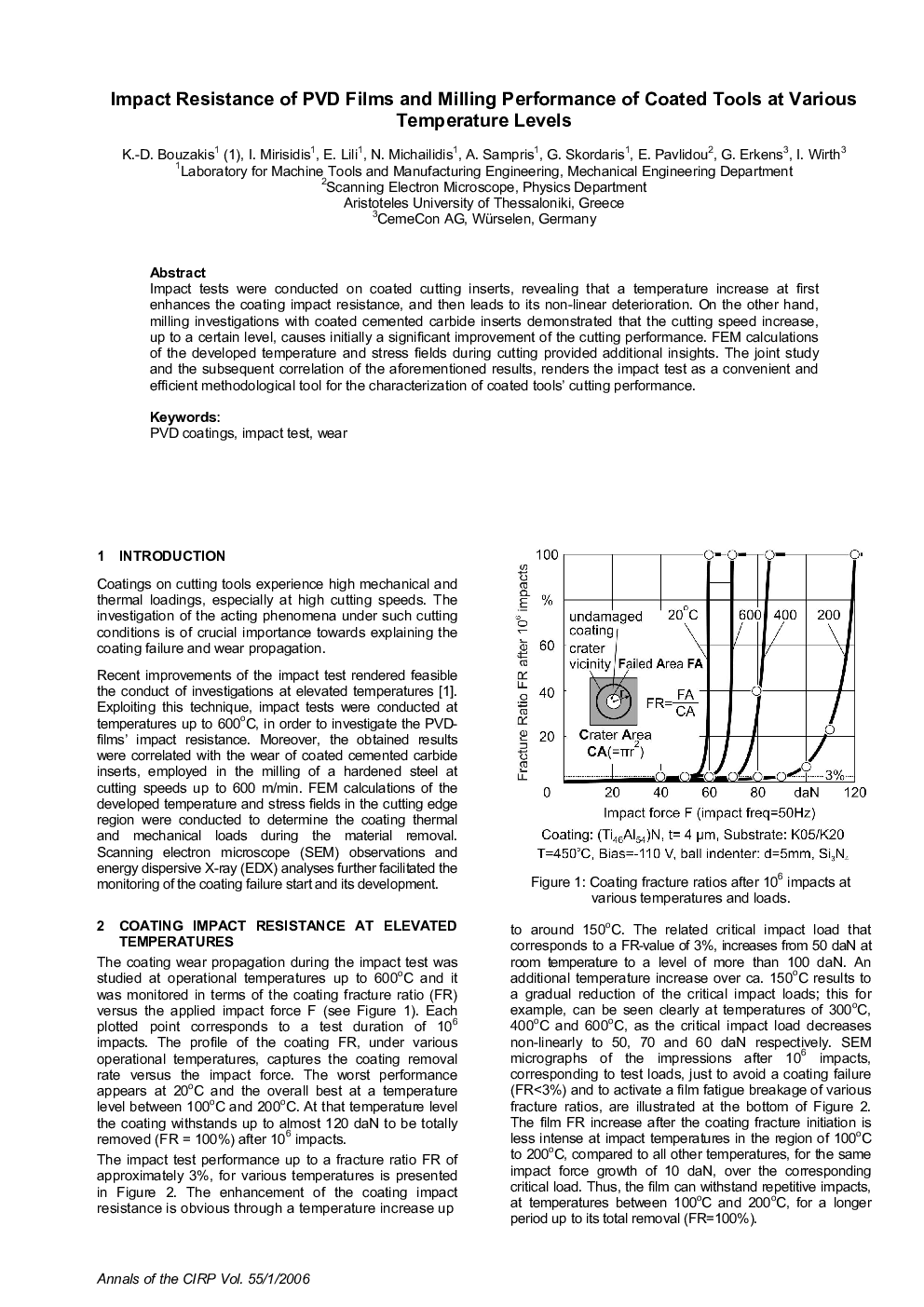

Impact tests were conducted on coated cutting inserts, revealing that a temperature increase at first enhances the coating impact resistance, and then leads to its non-linear deterioration. On the other hand, milling investigations with coated cemented carbide inserts demonstrated that the cutting speed increase, up to a certain level, causes initially a significant improvement of the cutting performance. FEM calculations of the developed temperature and stress fields during cutting provided additional insights. The joint study and the subsequent correlation of the aforementioned results, renders the impact test as a convenient and efficient methodological tool for the characterization of coated tools' cutting performance.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering