| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679583 | CIRP Annals - Manufacturing Technology | 2006 | 6 Pages |

Abstract

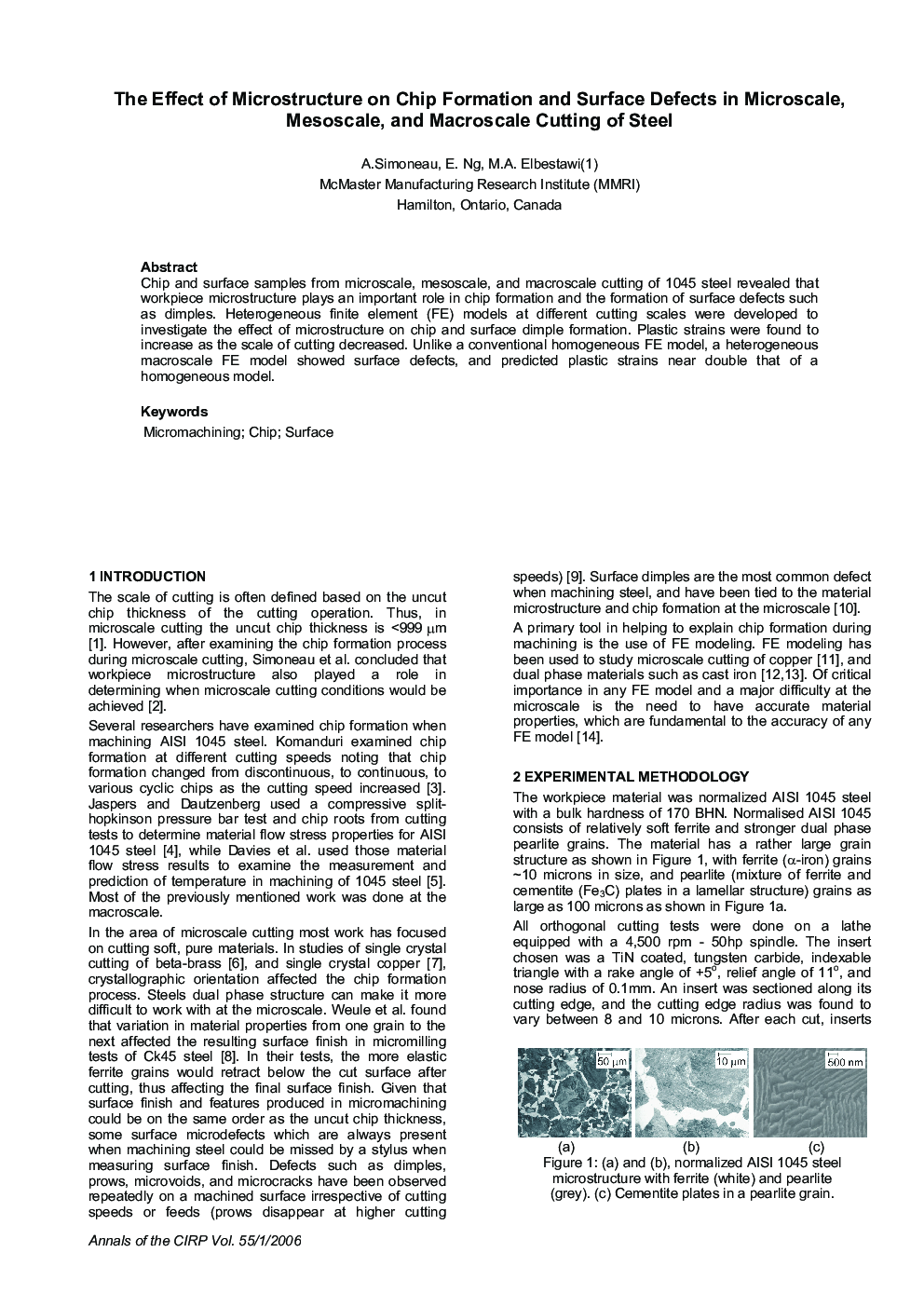

Chip and surface samples from microscale, mesoscale, and macroscale cutting of 1045 steel revealed that workpiece microstructure plays an important role in chip formation and the formation of surface defects such as dimples. Heterogeneous finite element (FE) models at different cutting scales were developed to investigate the effect of microstructure on chip and surface dimple formation. Plastic strains were found to increase as the scale of cutting decreased. Unlike a conventional homogeneous FE model, a heterogeneous macroscale FE model showed surface defects, and predicted plastic strains near double that of a homogeneous model.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering