| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679586 | CIRP Annals - Manufacturing Technology | 2006 | 6 Pages |

Abstract

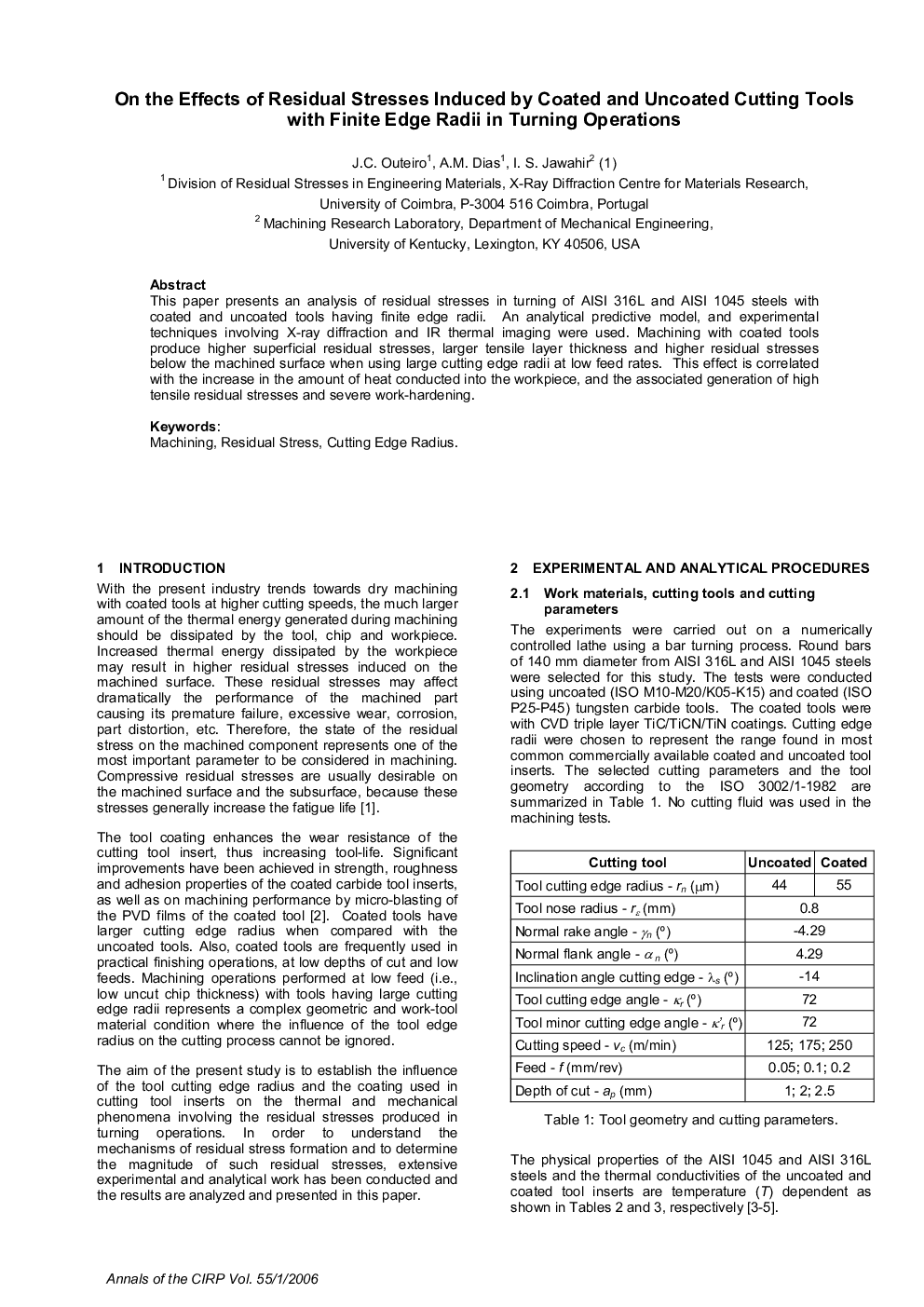

This paper presents an analysis of residual stresses in turning of AISI 316L and AISI 1045 steels with coated and uncoated tools having finite edge radii. An analytical predictive model, and experimental techniques involving X-ray diffraction and IR thermal imaging were used. Machining with coated tools produce higher superficial residual stresses, larger tensile layer thickness and higher residual stresses below the machined surface when using large cutting edge radii at low feed rates. This effect is correlated with the increase in the amount of heat conducted into the workpiece, and the associated generation of high tensile residual stresses and severe work-hardening.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering