| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679604 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

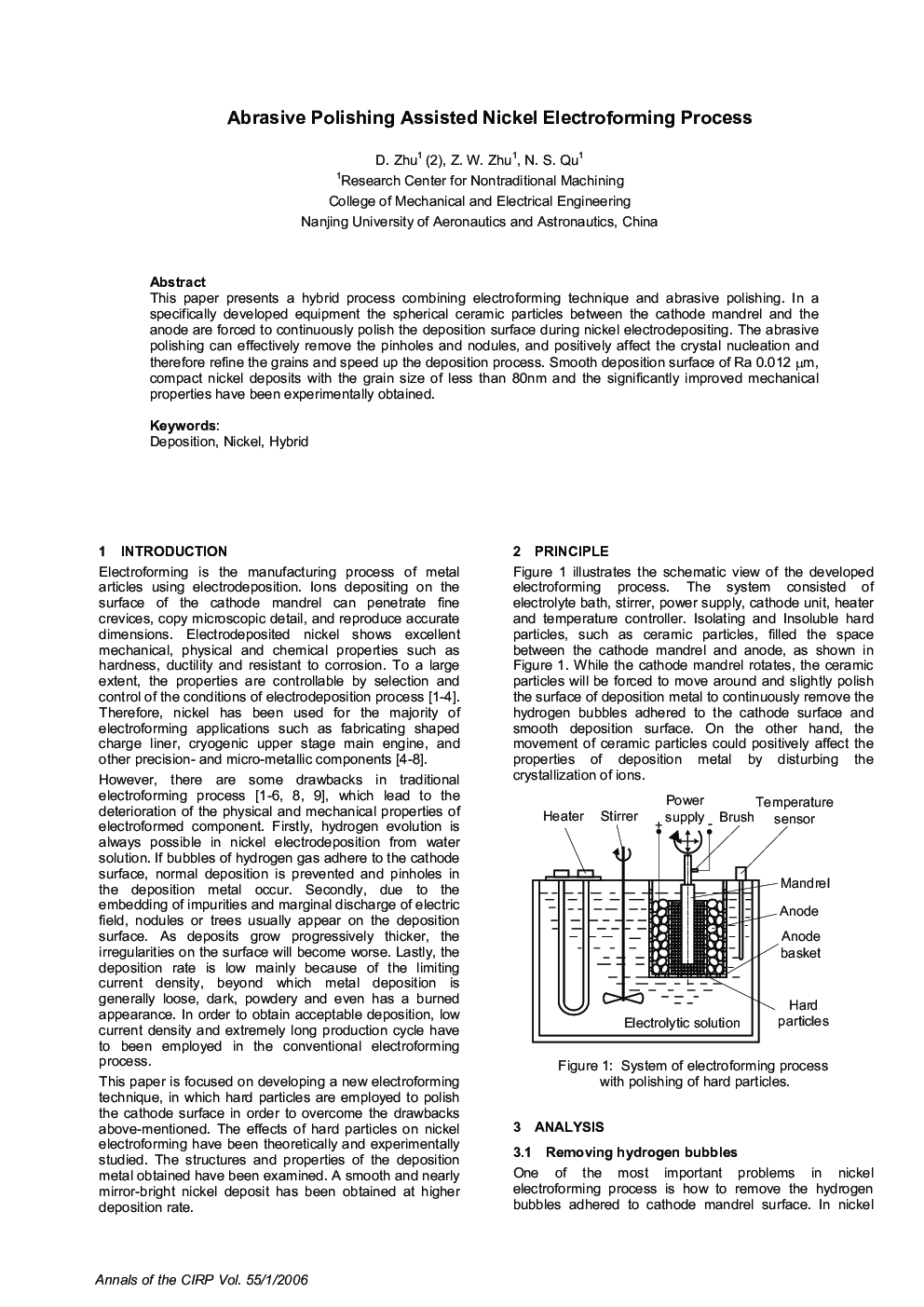

This paper presents a hybrid process combining electroforming technique and abrasive polishing. In a specifically developed equipment the spherical ceramic particles between the cathode mandrel and the anode are forced to continuously polish the deposition surface during nickel electrodepositing. The abrasive polishing can effectively remove the pinholes and nodules, and positively affect the crystal nucleation and therefore refine the grains and speed up the deposition process. Smooth deposition surface of Ra 0.012 μm, compact nickel deposits with the grain size of less than 80nm and the significantly improved mechanical properties have been experimentally obtained.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering