| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679618 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

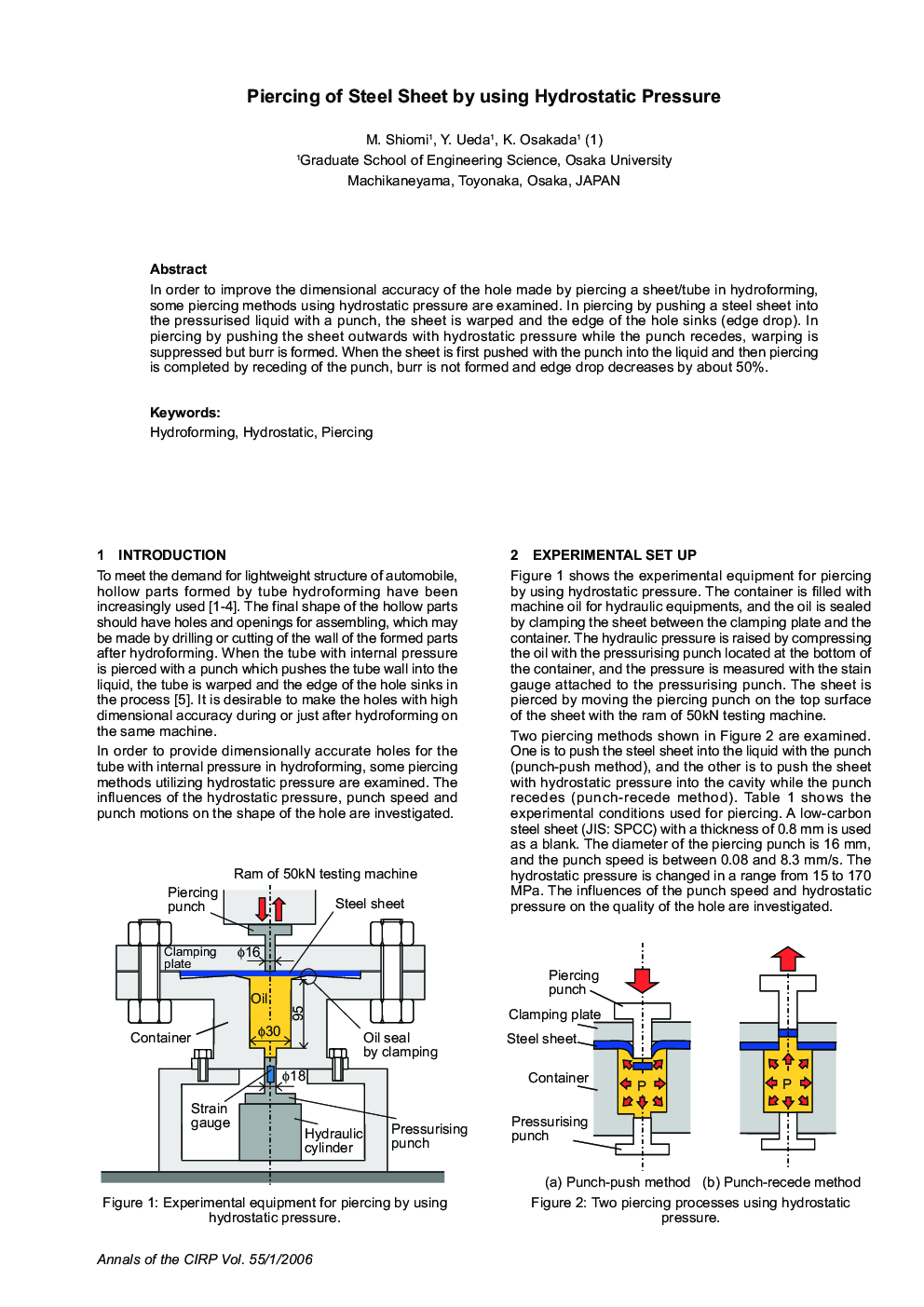

In order to improve the dimensional accuracy of the hole made by piercing a sheet/tube in hydroforming, some piercing methods using hydrostatic pressure are examined. In piercing by pushing a steel sheet into the pressurised liquid with a punch, the sheet is warped and the edge of the hole sinks (edge drop). In piercing by pushing the sheet outwards with hydrostatic pressure while the punch recedes, warping is suppressed but burr is formed. When the sheet is first pushed with the punch into the liquid and then piercing is completed by receding of the punch, burr is not formed and edge drop decreases by about 50%.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering