| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679621 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

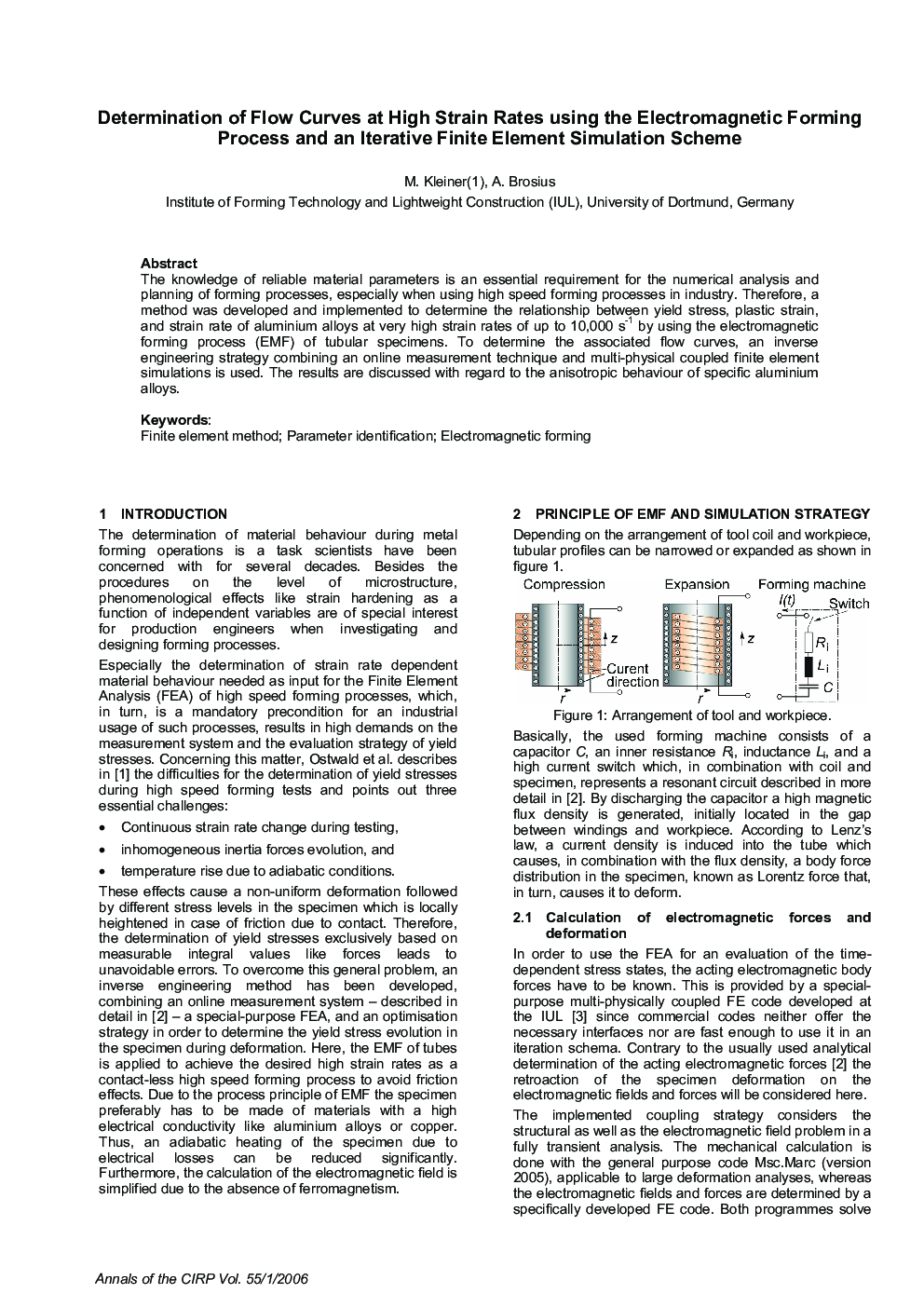

The knowledge of reliable material parameters is an essential requirement for the numerical analysis and planning of forming processes, especially when using high speed forming processes in industry. Therefore, a method was developed and implemented to determine the relationship between yield stress, plastic strain, and strain rate of aluminium alloys at very high strain rates of up to 10,000 s-1 by using the electromagnetic forming process (EMF) of tubular specimens. To determine the associated flow curves, an inverse engineering strategy combining an online measurement technique and multi-physical coupled finite element simulations is used. The results are discussed with regard to the anisotropic behaviour of specific aluminium alloys.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering