| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679629 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

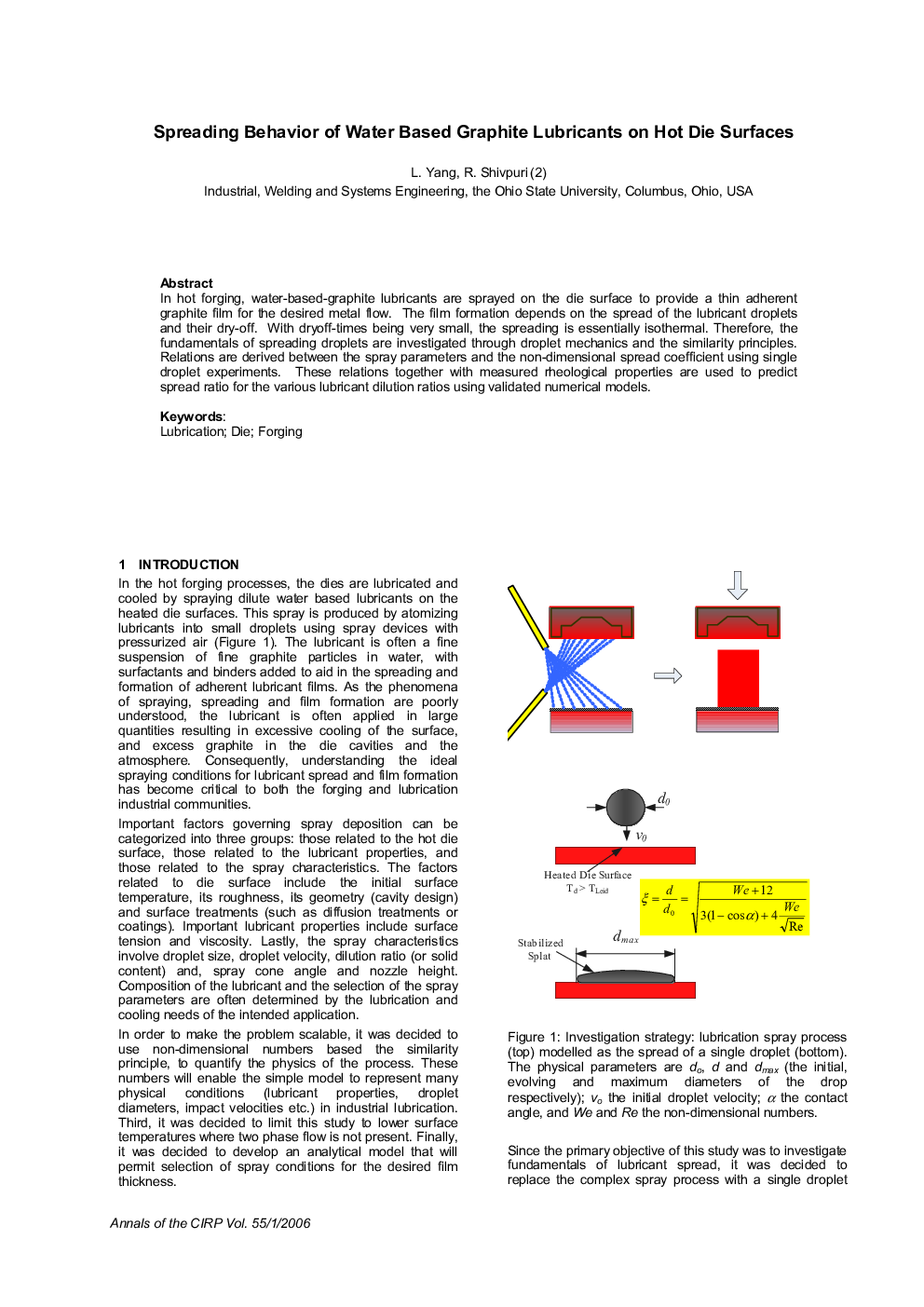

In hot forging, water-based-graphite lubricants are sprayed on the die surface to provide a thin adherent graphite film for the desired metal flow. The film formation depends on the spread of the lubricant droplets and their dry-off. With dryoff-times being very small, the spreading is essentially isothermal. Therefore, the fundamentals of spreading droplets are investigated through droplet mechanics and the similarity principles. Relations are derived between the spray parameters and the non-dimensional spread coefficient using single droplet experiments. These relations together with measured rheological properties are used to predict spread ratio for the various lubricant dilution ratios using validated numerical models.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering