| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679634 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

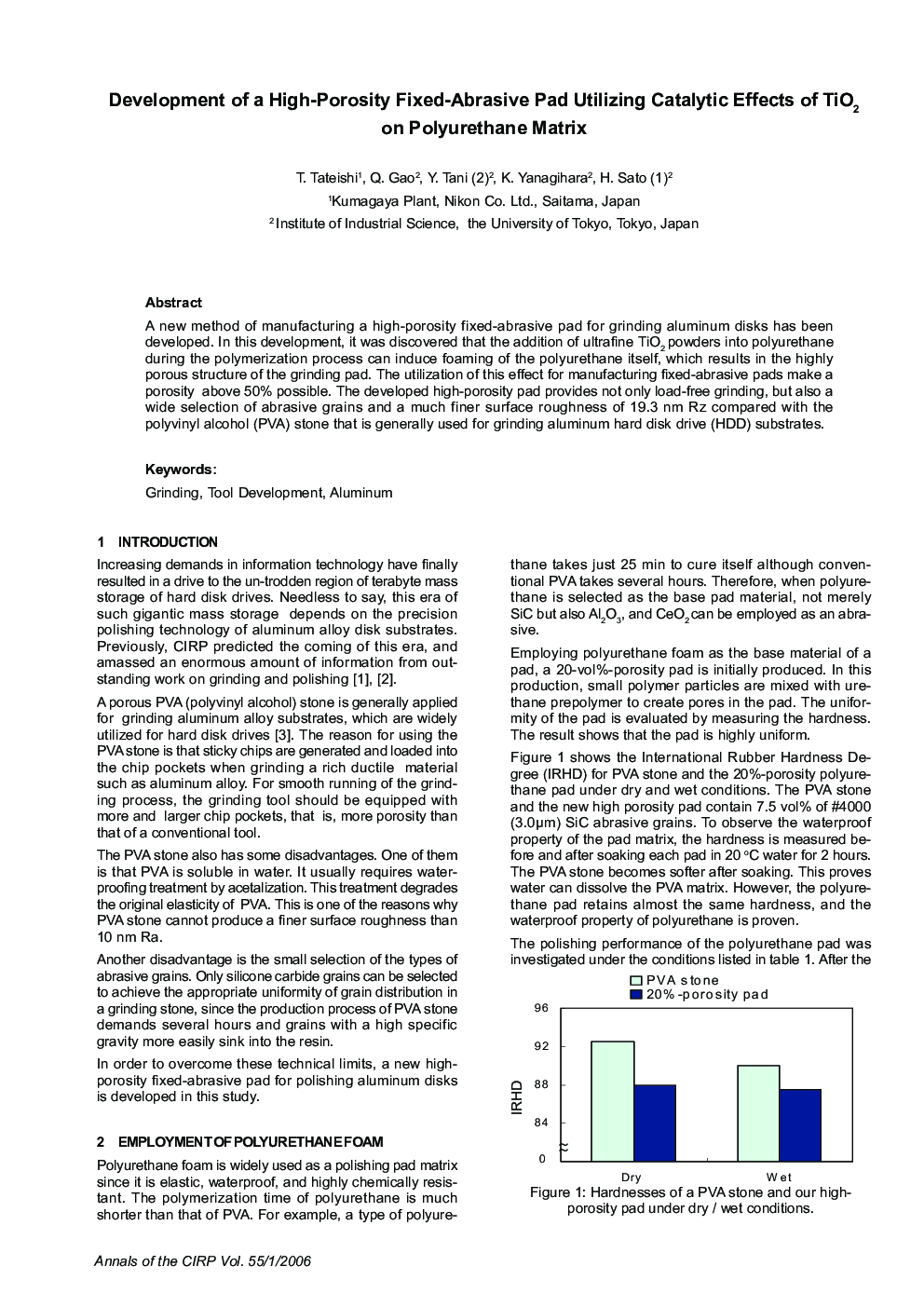

A new method of manufacturing a high-porosity fixed-abrasive pad for grinding aluminum disks has been developed. In this development, it was discovered that the addition of ultrafine TiO2 powders into polyurethane during the polymerization process can induce foaming of the polyurethane itself, which results in the highly porous structure of the grinding pad. The utilization of this effect for manufacturing fixed-abrasive pads make a porosity above 50% possible. The developed high-porosity pad provides not only load-free grinding, but also a wide selection of abrasive grains and a much finer surface roughness of 19.3 nm Rz compared with the polyvinyl alcohol (PVA) stone that is generally used for grinding aluminum hard disk drive (HDD) substrates.