| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679637 | CIRP Annals - Manufacturing Technology | 2006 | 6 Pages |

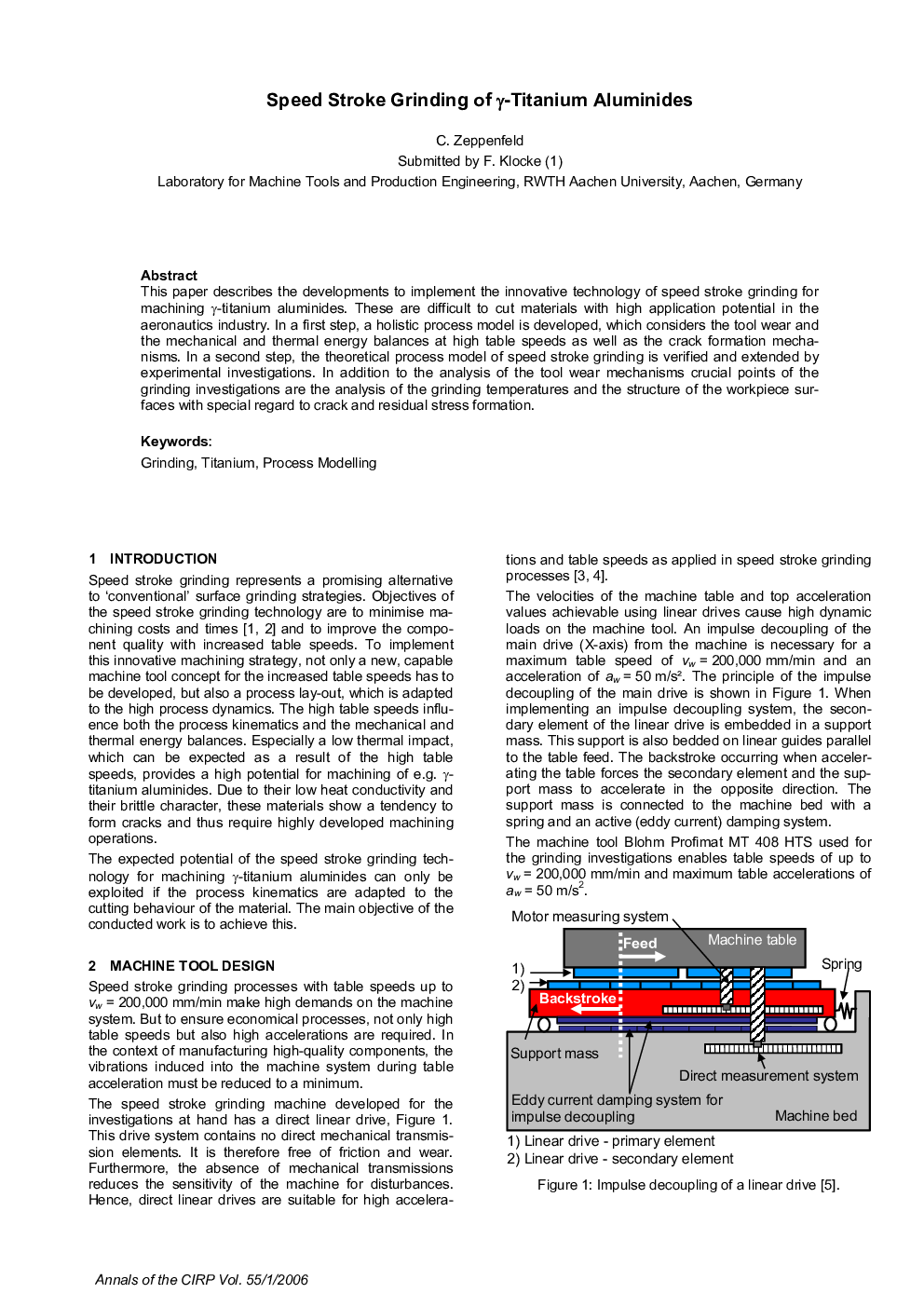

This paper describes the developments to implement the innovative technology of speed stroke grinding for machining γ-titanium aluminides. These are difficult to cut materials with high application potential in the aeronautics industry. In a first step, a holistic process model is developed, which considers the tool wear and the mechanical and thermal energy balances at high table speeds as well as the crack formation mechanisms. In a second step, the theoretical process model of speed stroke grinding is verified and extended by experimental investigations. In addition to the analysis of the tool wear mechanisms crucial points of the grinding investigations are the analysis of the grinding temperatures and the structure of the workpiece surfaces with special regard to crack and residual stress formation.