| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679649 | CIRP Annals - Manufacturing Technology | 2006 | 4 Pages |

Abstract

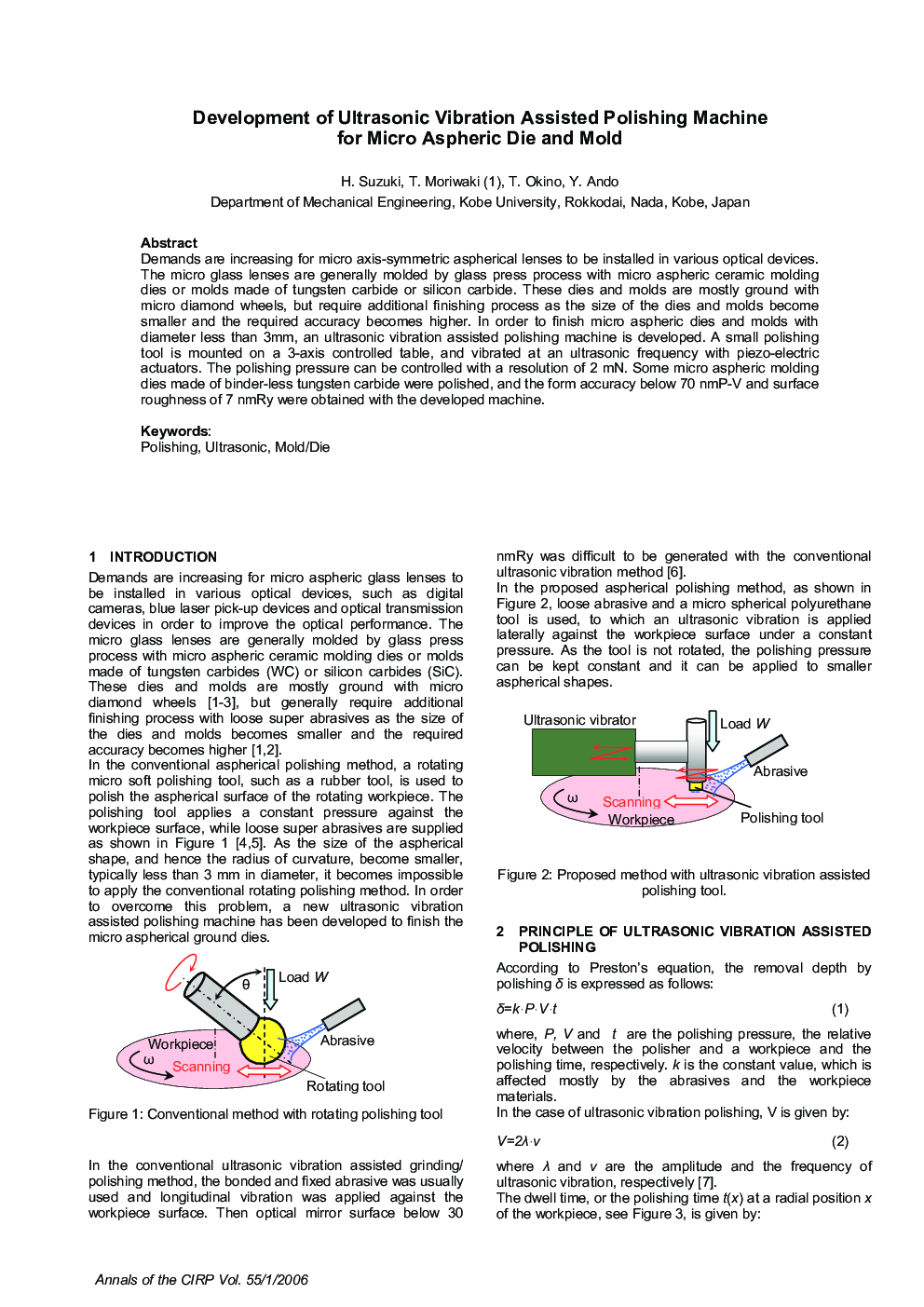

Demands are increasing for micro axis-symmetric aspherical lenses to be installed in various optical devices. The micro glass lenses are generally molded by glass press process with micro aspheric ceramic molding dies or molds made of tungsten carbide or silicon carbide. These dies and molds are mostly ground with micro diamond wheels, but require additional finishing process as the size of the dies and molds become smaller and the required accuracy becomes higher. In order to finish micro aspheric dies and molds with diameter less than 3mm, an ultrasonic vibration assisted polishing machine is developed. A small polishing tool is mounted on a 3-axis controlled table, and vibrated at an ultrasonic frequency with piezo-electric actuators. The polishing pressure can be controlled with a resolution of 2 mN. Some micro aspheric molding dies made of binder-less tungsten carbide were polished, and the form accuracy below 70 nmP-V and surface roughness of 7 nmRy were obtained with the developed machine.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

H. Suzuki, T. Moriwaki, T. Okino, Y. Ando,