| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1691072 | Vacuum | 2009 | 4 Pages |

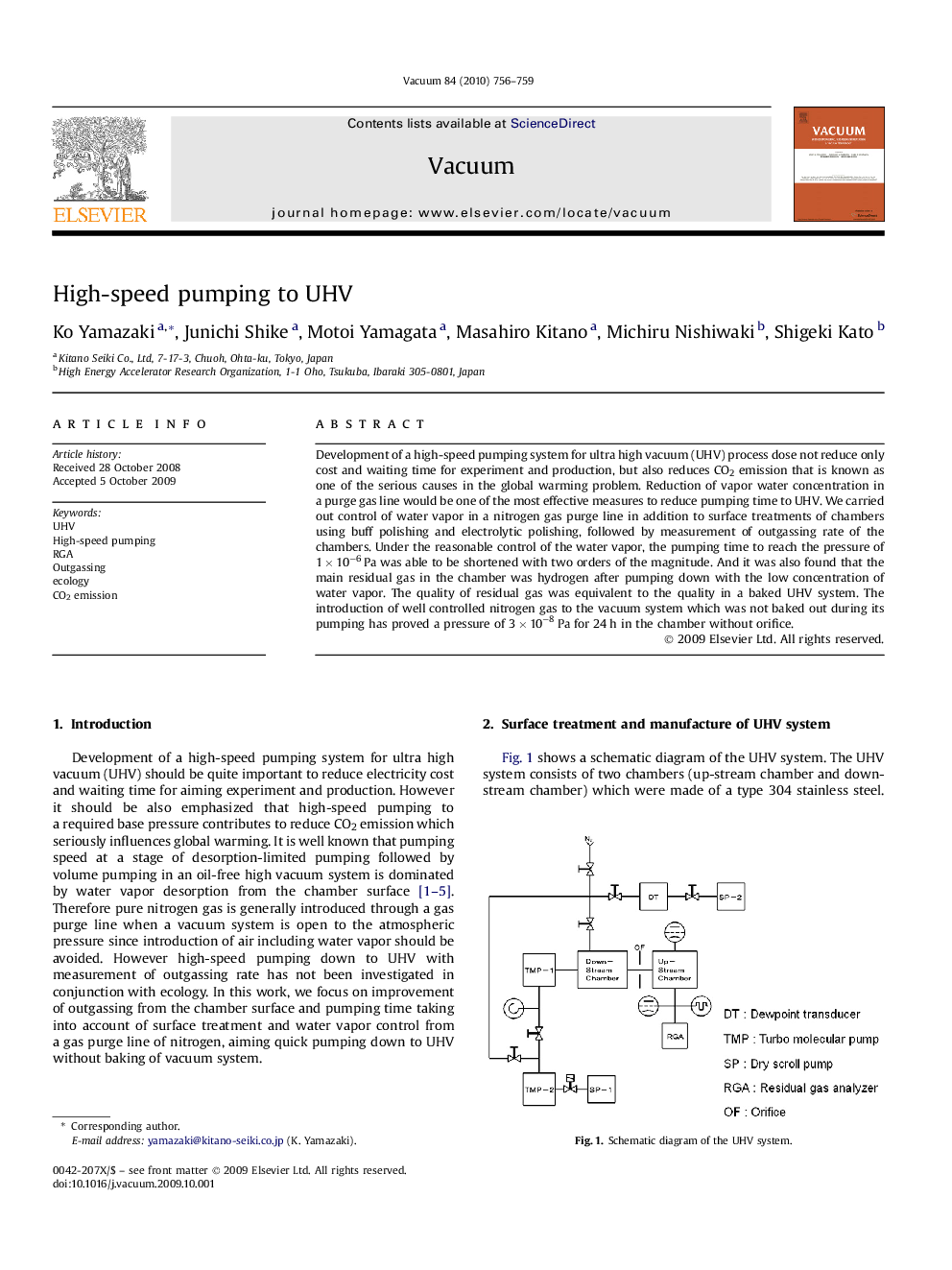

Development of a high-speed pumping system for ultra high vacuum (UHV) process dose not reduce only cost and waiting time for experiment and production, but also reduces CO2 emission that is known as one of the serious causes in the global warming problem. Reduction of vapor water concentration in a purge gas line would be one of the most effective measures to reduce pumping time to UHV. We carried out control of water vapor in a nitrogen gas purge line in addition to surface treatments of chambers using buff polishing and electrolytic polishing, followed by measurement of outgassing rate of the chambers. Under the reasonable control of the water vapor, the pumping time to reach the pressure of 1 × 10−6 Pa was able to be shortened with two orders of the magnitude. And it was also found that the main residual gas in the chamber was hydrogen after pumping down with the low concentration of water vapor. The quality of residual gas was equivalent to the quality in a baked UHV system. The introduction of well controlled nitrogen gas to the vacuum system which was not baked out during its pumping has proved a pressure of 3 × 10−8 Pa for 24 h in the chamber without orifice.