| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1697722 | Journal of Manufacturing Systems | 2012 | 7 Pages |

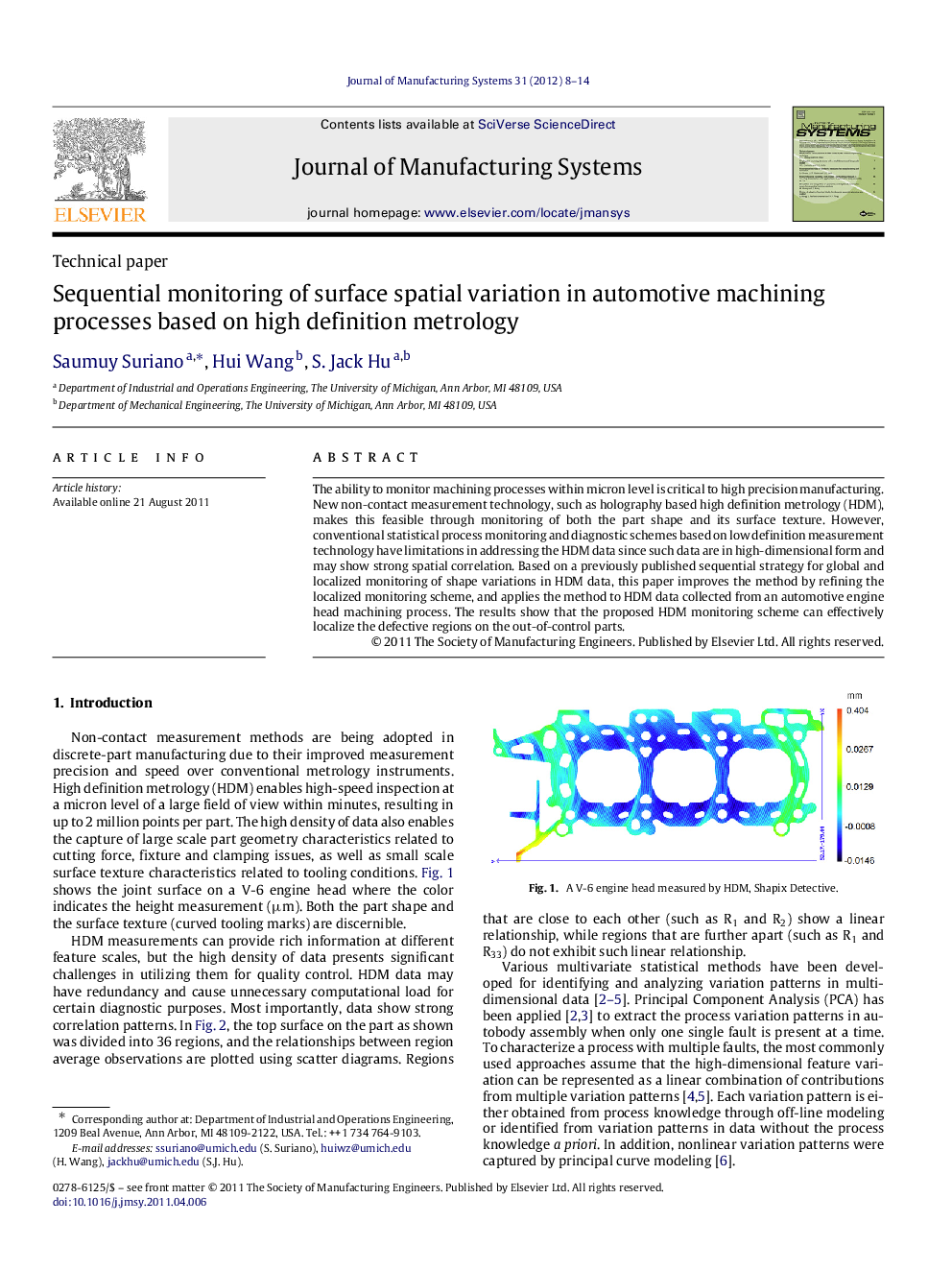

The ability to monitor machining processes within micron level is critical to high precision manufacturing. New non-contact measurement technology, such as holography based high definition metrology (HDM), makes this feasible through monitoring of both the part shape and its surface texture. However, conventional statistical process monitoring and diagnostic schemes based on low definition measurement technology have limitations in addressing the HDM data since such data are in high-dimensional form and may show strong spatial correlation. Based on a previously published sequential strategy for global and localized monitoring of shape variations in HDM data, this paper improves the method by refining the localized monitoring scheme, and applies the method to HDM data collected from an automotive engine head machining process. The results show that the proposed HDM monitoring scheme can effectively localize the defective regions on the out-of-control parts.