| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1698371 | Procedia CIRP | 2016 | 4 Pages |

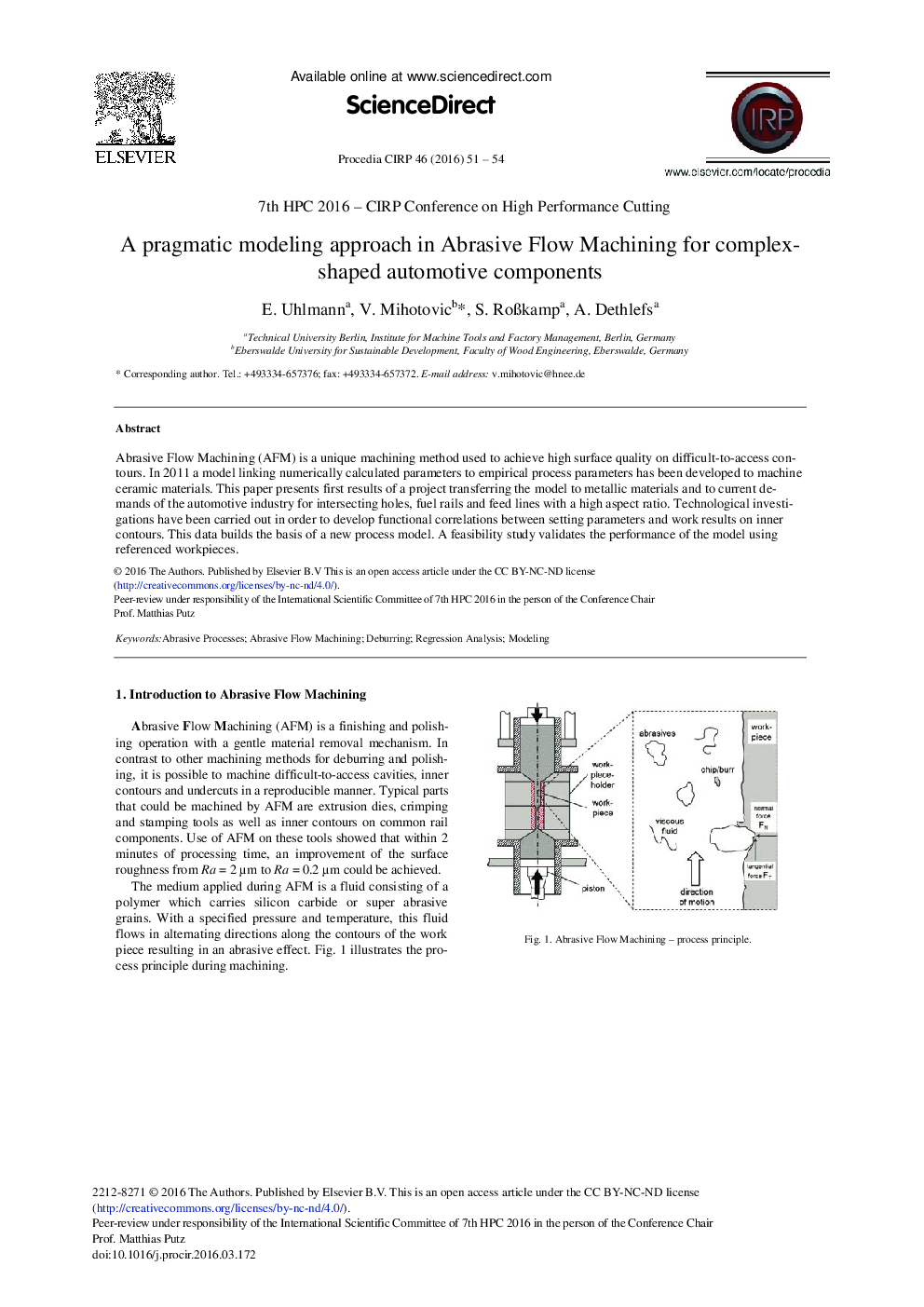

Abrasive Flow Machining (AFM) is a unique machining method used to achieve high surface quality on difficult-to-access contours. In 2011 a model linking numerically calculated parameters to empirical process parameters has been developed to machine ceramic materials. This paper presents first results of a project transferring the model to metallic materials and to current demands of the automotive industry for intersecting holes, fuel rails and feed lines with a high aspect ratio. Technological investigations have been carried out in order to develop functional correlations between setting parameters and work results on inner contours. This data builds the basis of a new process model. A feasibility study validates the performance of the model using referenced workpieces.