| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1698459 | Procedia CIRP | 2016 | 4 Pages |

Abstract

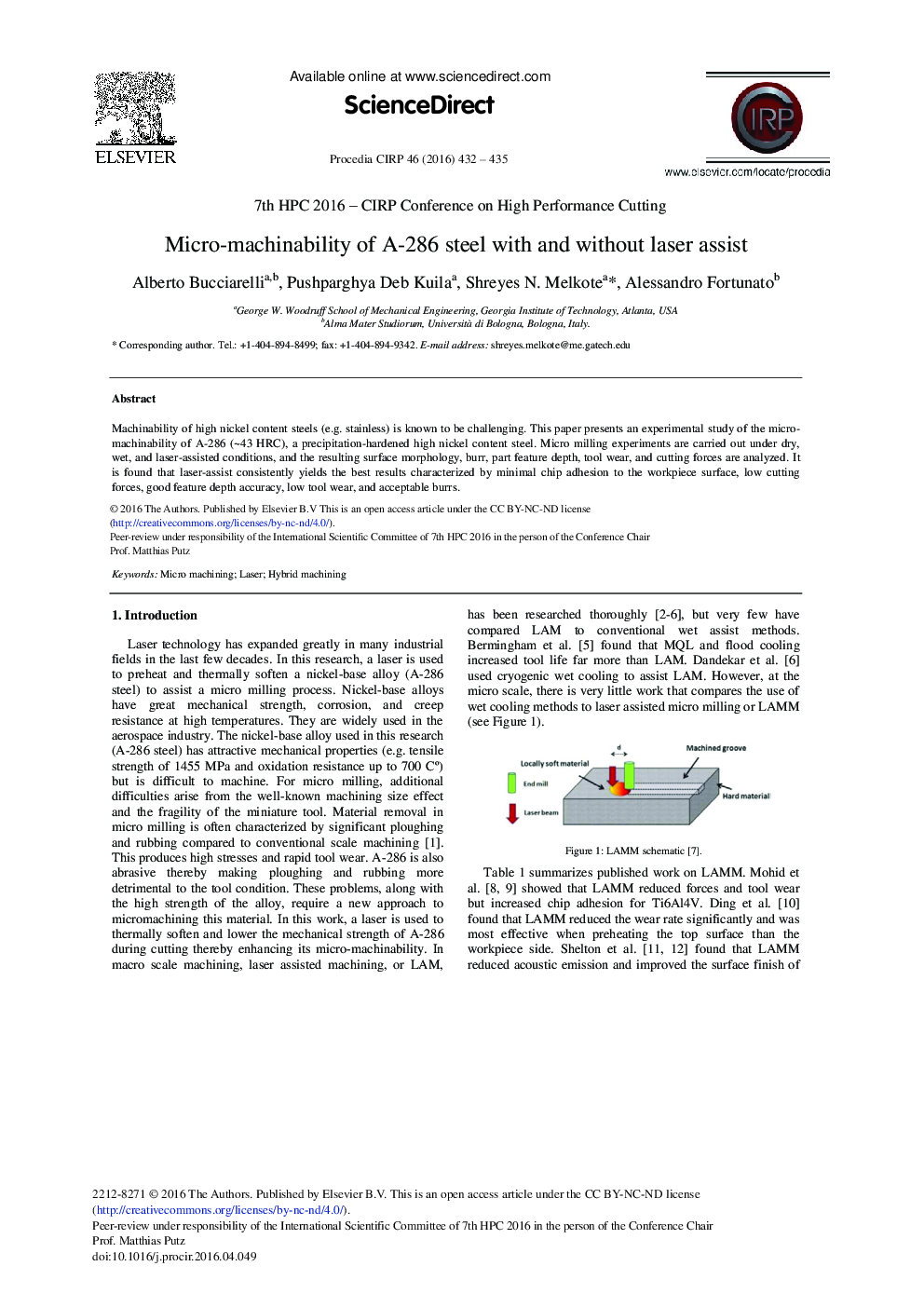

Machinability of high nickel content steels (e.g. stainless) is known to be challenging. This paper presents an experimental study of the micro-machinability of A-286 (∼43 HRC), a precipitation-hardened high nickel content steel. Micro milling experiments are carried out under dry, wet, and laser-assisted conditions, and the resulting surface morphology, burr, part feature depth, tool wear, and cutting forces are analyzed. It is found that laser-assist consistently yields the best results characterized by minimal chip adhesion to the workpiece surface, low cutting forces, good feature depth accuracy, low tool wear, and acceptable burrs.

Keywords

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Alberto Bucciarelli, Pushparghya Deb Kuila, Shreyes N. Melkote, Alessandro Fortunato,