| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1698676 | Procedia CIRP | 2016 | 6 Pages |

Abstract

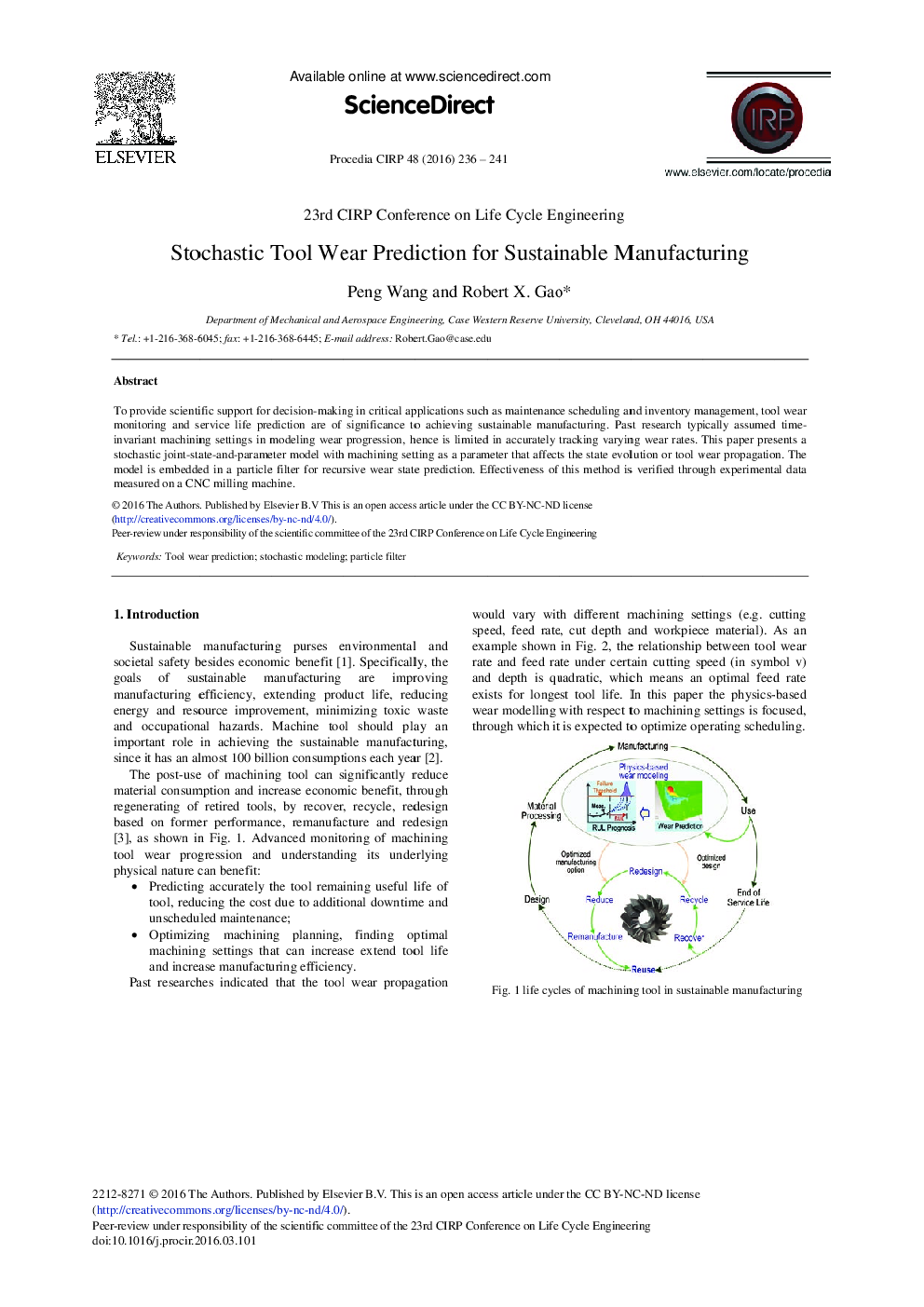

To provide scientific support for decision-making in critical applications such as maintenance scheduling and inventory management, tool wear monitoring and service life prediction are of significance to achieving sustainable manufacturing. Past research typically assumed time-invariant machining settings in modeling wear progression, hence is limited in accurately tracking varying wear rates. This paper presents a stochastic joint-state-and-parameter model with machining setting as a parameter that affects the state evolution or tool wear propagation. The model is embedded in a particle filter for recursive wear state prediction. Effectiveness of this method is verified through experimental data measured on a CNC milling machine.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Peng Wang, Robert X. Gao,