| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1700157 | Procedia CIRP | 2014 | 9 Pages |

Abstract

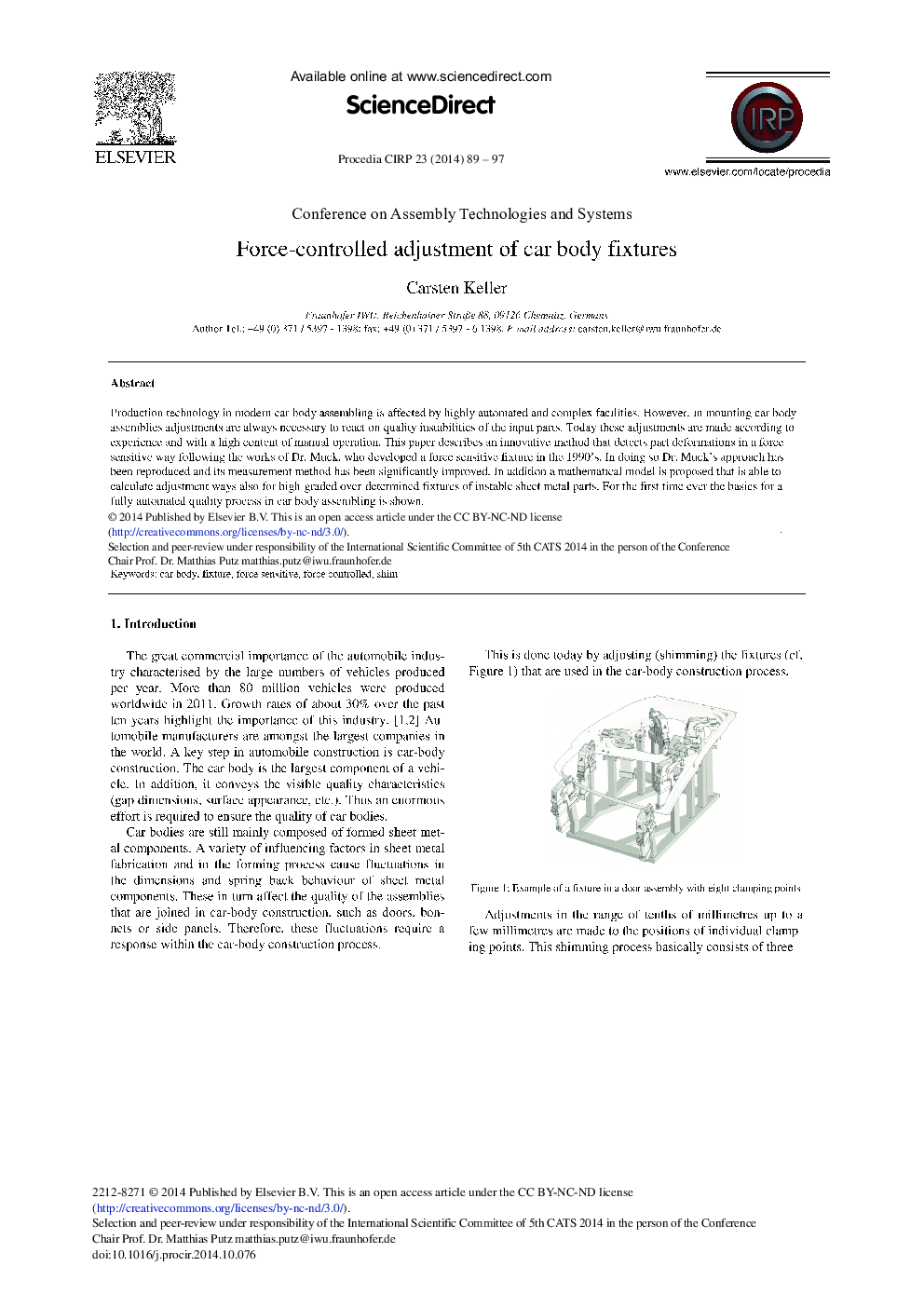

Production technology in modern car body assembling is affected by highly automated and complex facilities. However, in mounting car body assemblies adjustments are always necessary to react on quality instabilities of the input parts. Today these adjustments are made according to experience and with a high content of manual operation. This paper describes an innovative method that detects part deformations in a force sensitive way following the works of Dr. Muck, who developed a force sensitive fixture in the 1990's. In doing so Dr. Muck's approach has been reproduced and its measurement method has been significantly improved. In addition a mathematical model is proposed that is able to calculate adjustment ways also for high-graded over-determined fixtures of instable sheet metal parts. For the first time ever the basics for a fully automated quality process in car body assembling is shown.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Carsten Keller,