| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1701475 | Procedia CIRP | 2012 | 6 Pages |

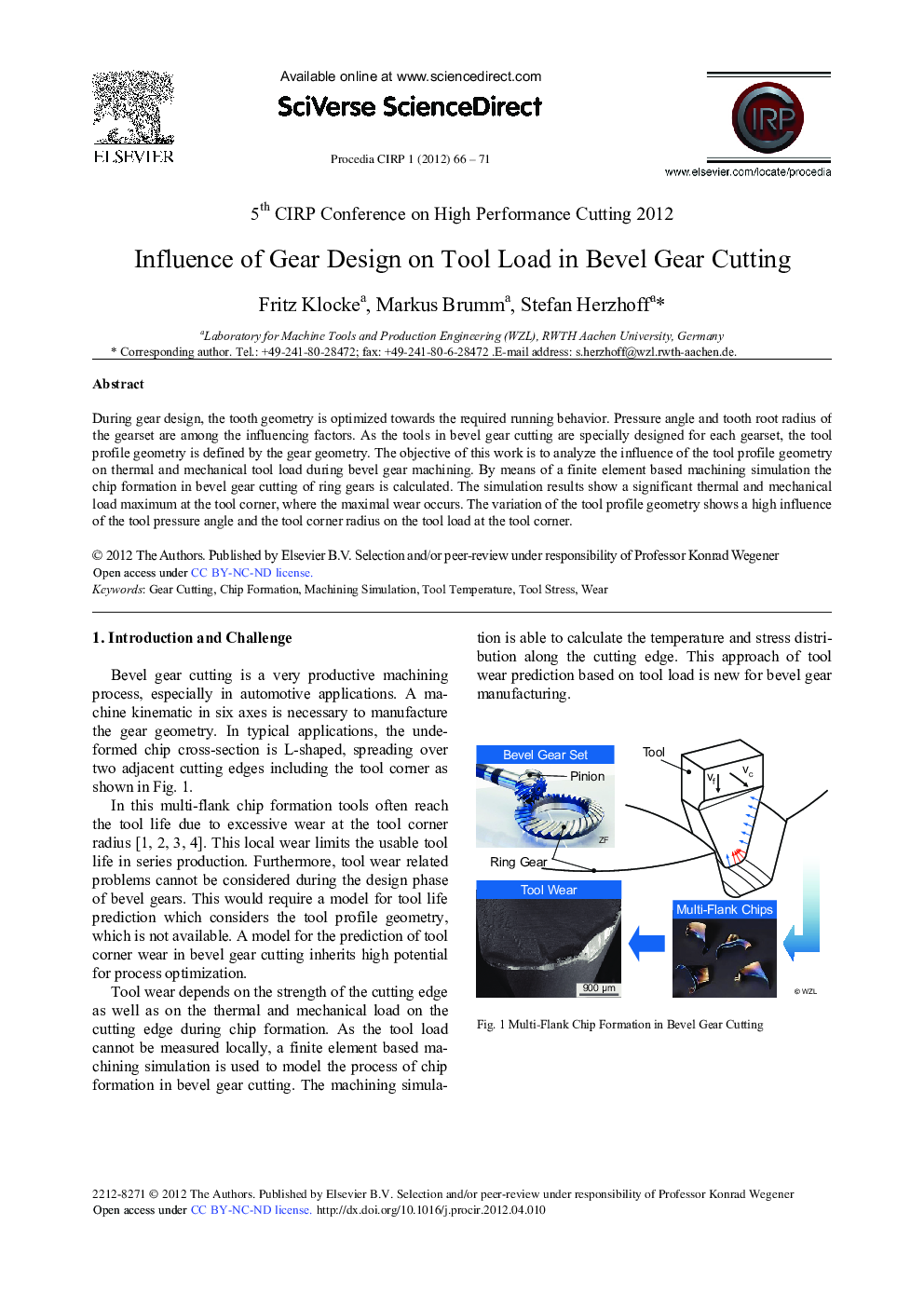

During gear design, the tooth geometry is optimized towards the required running behavior. Pressure angle and tooth root radius of the gearset are among the influencing factors. As the tools in bevel gear cutting are specially designed for each gearset, the tool profile geometry is defined by the gear geometry. The objective of this work is to analyze the influence of the tool profile geometry on thermal and mechanical tool load during bevel gear machining. By means of a finite element based machining simulation the chip formation in bevel gear cutting of ring gears is calculated. The simulation results show a significant thermal and mechanical load maximum at the tool corner, where the maximal wear occurs. The variation of the tool profile geometry shows a high influence of the tool pressure angle and the tool corner radius on the tool load at the tool corner.