| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1701506 | Procedia CIRP | 2012 | 5 Pages |

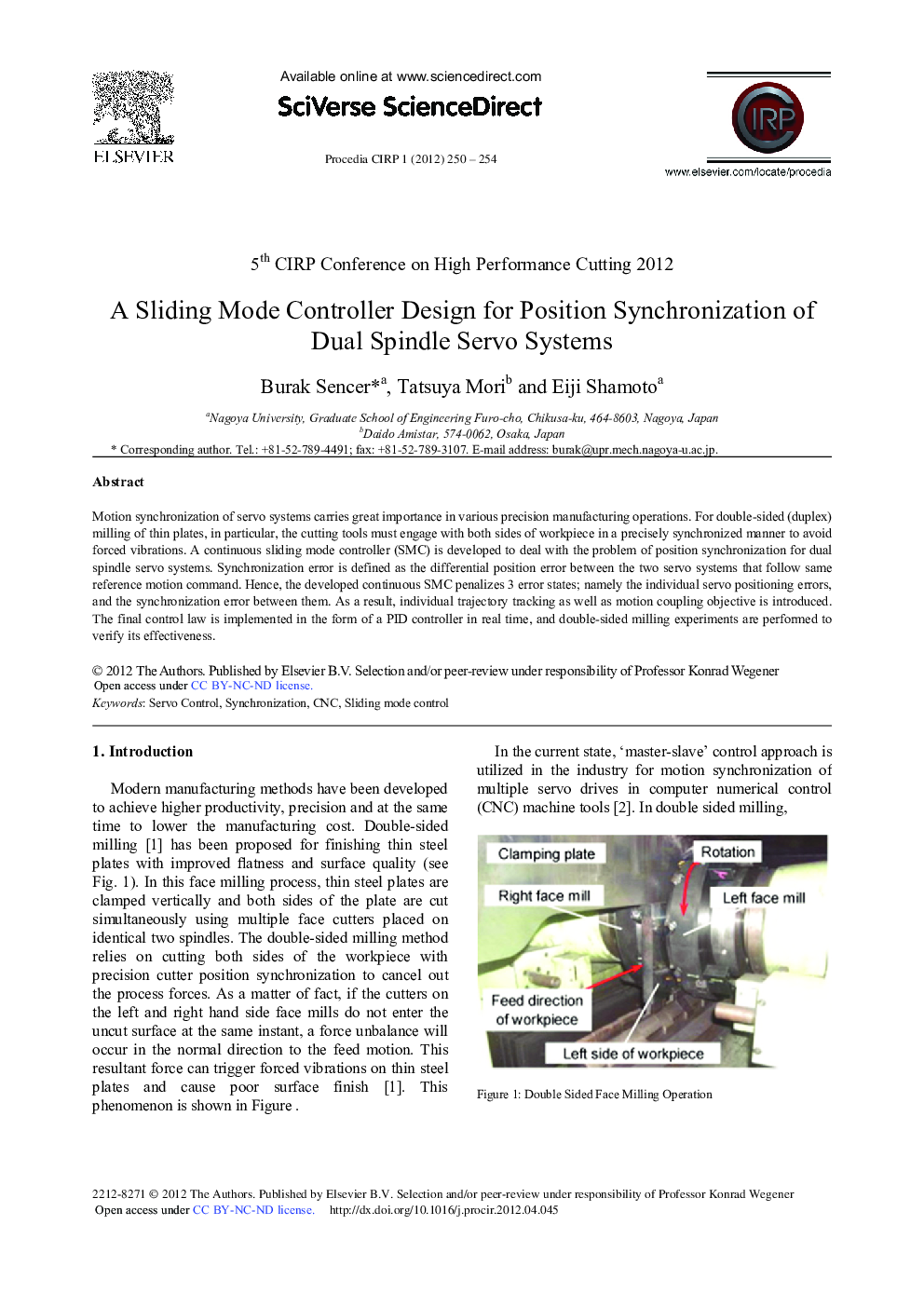

Motion synchronization of servo systems carries great importance in various precision manufacturing operations. For double-sided (duplex) milling of thin plates, in particular, the cutting tools must engage with both sides of workpiece in a precisely synchronized manner to avoid forced vibrations. A continuous sliding mode controller (SMC) is developed to deal with the problem of position synchronization for dual spindle servo systems. Synchronization error is defined as the differential position error between the two servo systems that follow same reference motion command. Hence, the developed continuous SMC penalizes 3 error states; namely the individual servo positioning errors, and the synchronization error between them. As a result, individual trajectory tracking as well as motion coupling objective is introduced. The final control law is implemented in the form of a PID controller in real time, and double-sided milling experiments are performed to verify its effectiveness.