| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1701614 | Procedia CIRP | 2012 | 6 Pages |

Abstract

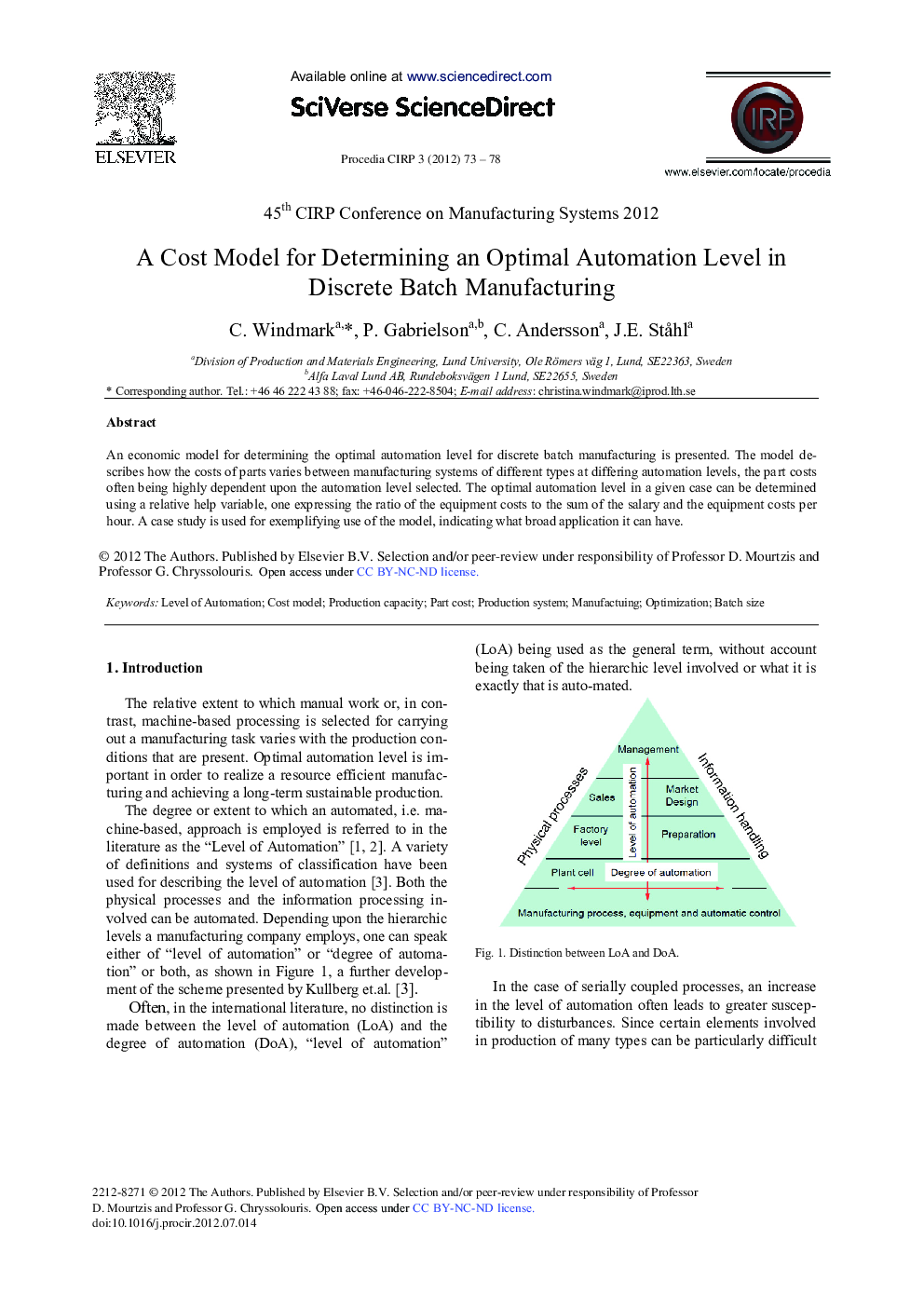

An economic model for determining the optimal automation level for discrete batch manufacturing is presented. The model de-scribes how the costs of parts varies between manufacturing systems of different types at differing automation levels, the part costs often being highly dependent upon the automation level selected. The optimal automation level in a given case can be determined using a relative help variable, one expressing the ratio of the equipment costs to the sum of the salary and the equipment costs per hour. A case study is used for exemplifying use of the model, indicating what broad application it can have.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering