| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1831762 | Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment | 2006 | 4 Pages |

Abstract

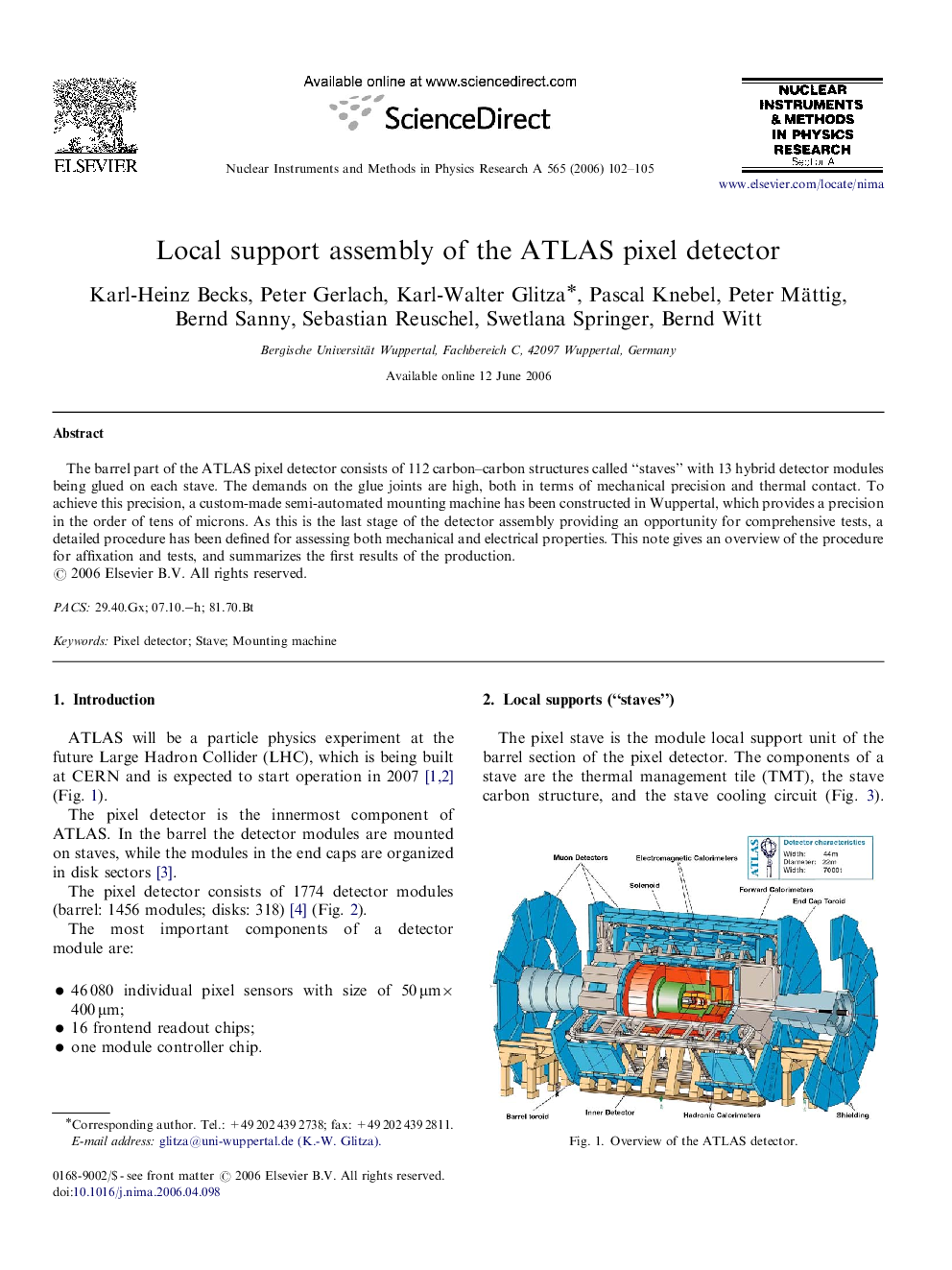

The barrel part of the ATLAS pixel detector consists of 112 carbon–carbon structures called “staves” with 13 hybrid detector modules being glued on each stave. The demands on the glue joints are high, both in terms of mechanical precision and thermal contact. To achieve this precision, a custom-made semi-automated mounting machine has been constructed in Wuppertal, which provides a precision in the order of tens of microns. As this is the last stage of the detector assembly providing an opportunity for comprehensive tests, a detailed procedure has been defined for assessing both mechanical and electrical properties. This note gives an overview of the procedure for affixation and tests, and summarizes the first results of the production.

Keywords

Related Topics

Physical Sciences and Engineering

Physics and Astronomy

Instrumentation

Authors

Karl-Heinz Becks, Peter Gerlach, Karl-Walter Glitza, Pascal Knebel, Peter Mättig, Bernd Sanny, Sebastian Reuschel, Swetlana Springer, Bernd Witt,