| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1873689 | Physics Procedia | 2011 | 7 Pages |

Abstract

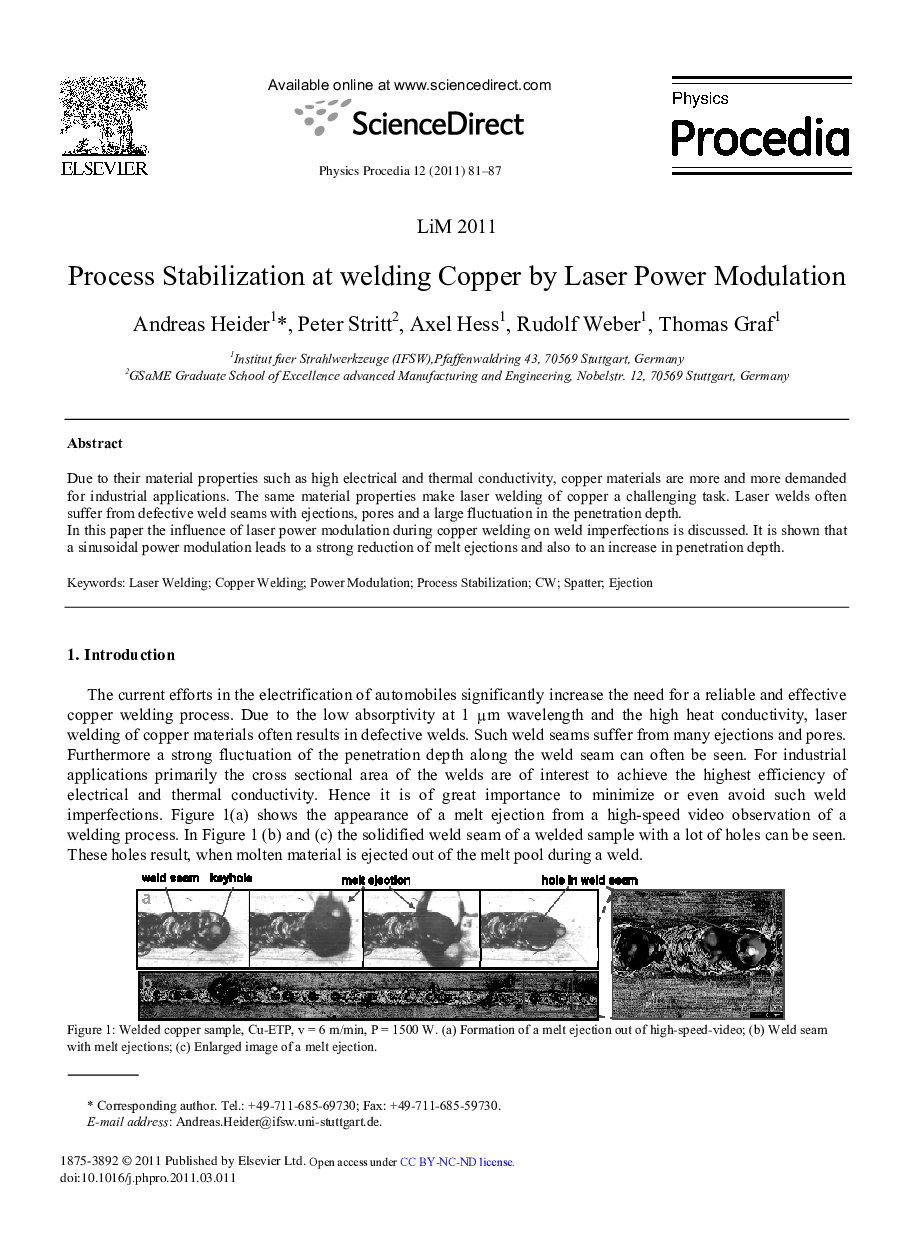

Due to their material properties such as high electrical and thermal conductivity, copper materials are more and more demanded for industrial applications. The same material properties make laser welding of copper a challenging task. Laser welds often suffer from defective weld seams with ejections, pores and a large fluctuation in the penetration depth. In this paper the influence of laser power modulation during copper welding on weld imperfections is discussed. It is shown that a sinusoidal power modulation leads to a strong reduction of melt ejections and also to an increase in penetration depth.

Related Topics

Physical Sciences and Engineering

Physics and Astronomy

Physics and Astronomy (General)