| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 204993 | Fuel | 2016 | 13 Pages |

Increasing the efficiency of coal power plants requires raising the operating temperature above 650 °C. However, coal ash can severely attack alloy materials at high temperature. For example, the corrosion rates of commercial Fe- and Ni-based alloys are generally greater than 2 mm/year at 750 °C in the gas environment of oxy-fuel combustion. Thus, a critical study is needed to determine the effect of the constituents in the ash on corrosion and find an approach to reduce the corrosion rates in an ash-laden environment at high temperature.The role of CaO in the ash (typical of U.S. Western coal ash) has been investigated in laboratory exposure environments with various structural alloys. Detailed results are presented on weight change, scale thickness, internal penetration, microstructural characteristics of corrosion products, and the cracking of scales for the alloys after exposure at 750 °C. The thermal stability of K3Al(SO4)3 under the environment of oxy-fuel combustion was determined by thermogravimetric analysis and differential thermal analysis. The reaction of this low melting temperature salt with the CaO-containing ash is discussed. In addition, we performed synchrotron nanobeam X-ray analysis to study the phase and chemical composition of the oxide layers on the alloy surface. Results from these studies are used to address the role of CaO in ash in the long-term corrosion performance of alloys.

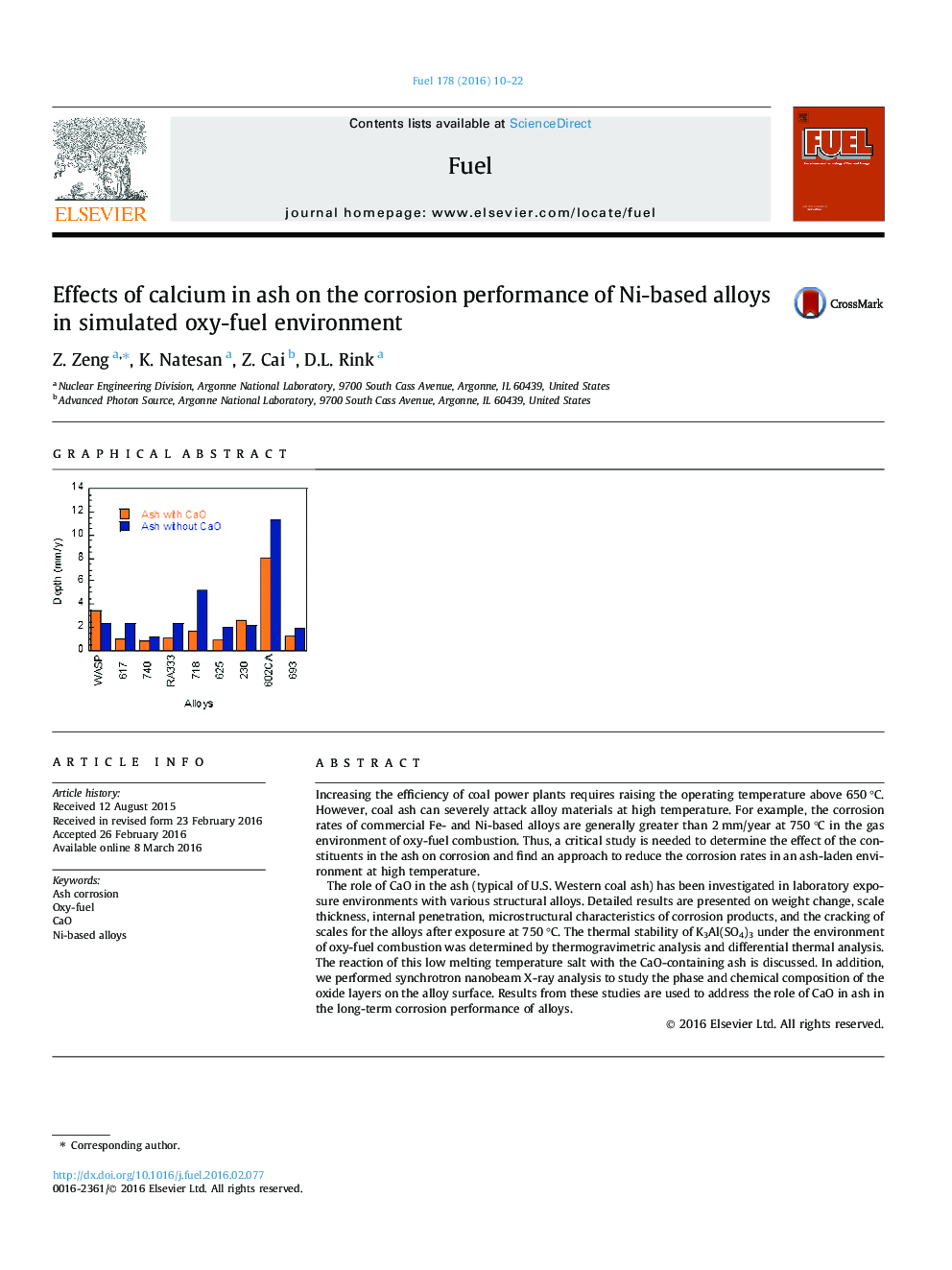

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide