| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205020 | Fuel | 2016 | 11 Pages |

•H2 was produced by ash-free coal catalytic steam gasification with CO2 capture.•H2 purity up to 85% (on dry basis with N2) was achieved in a fixed bed reactor.•The maximum gasification rate occurred with 20 wt% catalyst and Ca/C ratio of 2.•Carbon conversion of 97% was measured by elemental CHNS analysis of the residues.•CaO improves the H2 molar fraction while K2CO3 enhances the overall reaction rate.

This study is aimed at the improvement of process conditions for catalytic steam gasification of ash-free coal (AFC) integrated with CO2 capture. A novel modified catalytic hydrogen production reaction integrated gasification (M-HyPr-RING) process was proposed for high-purity H2 production from steam gasification of AFC. AFC was prepared from lignite coal by solvent extraction with maximum yields of 67% on a dry ash free basis at 400 °C using hydrotreated heavy aromatic hydrocarbons with a coal-to-solvent ratio of approximately 1:10.The gasification temperature and sorbent-to-carbon (CaO/C) ratio were maintained constant for all experiments at 675 °C and 2, respectively, as determined by our previous findings. The steam gasification experiments were conducted on AFC in a fixed-bed reactor in the presence of different catalyst loadings (5, 10 and 20 wt% of potassium carbonate) with and without sorbent. A maximum hydrogen molar fraction of 85% (dry basis with nitrogen) was observed with catalyst loading of 20% and CaO/C of 2 after 5 min of steam gasification under mild process conditions.

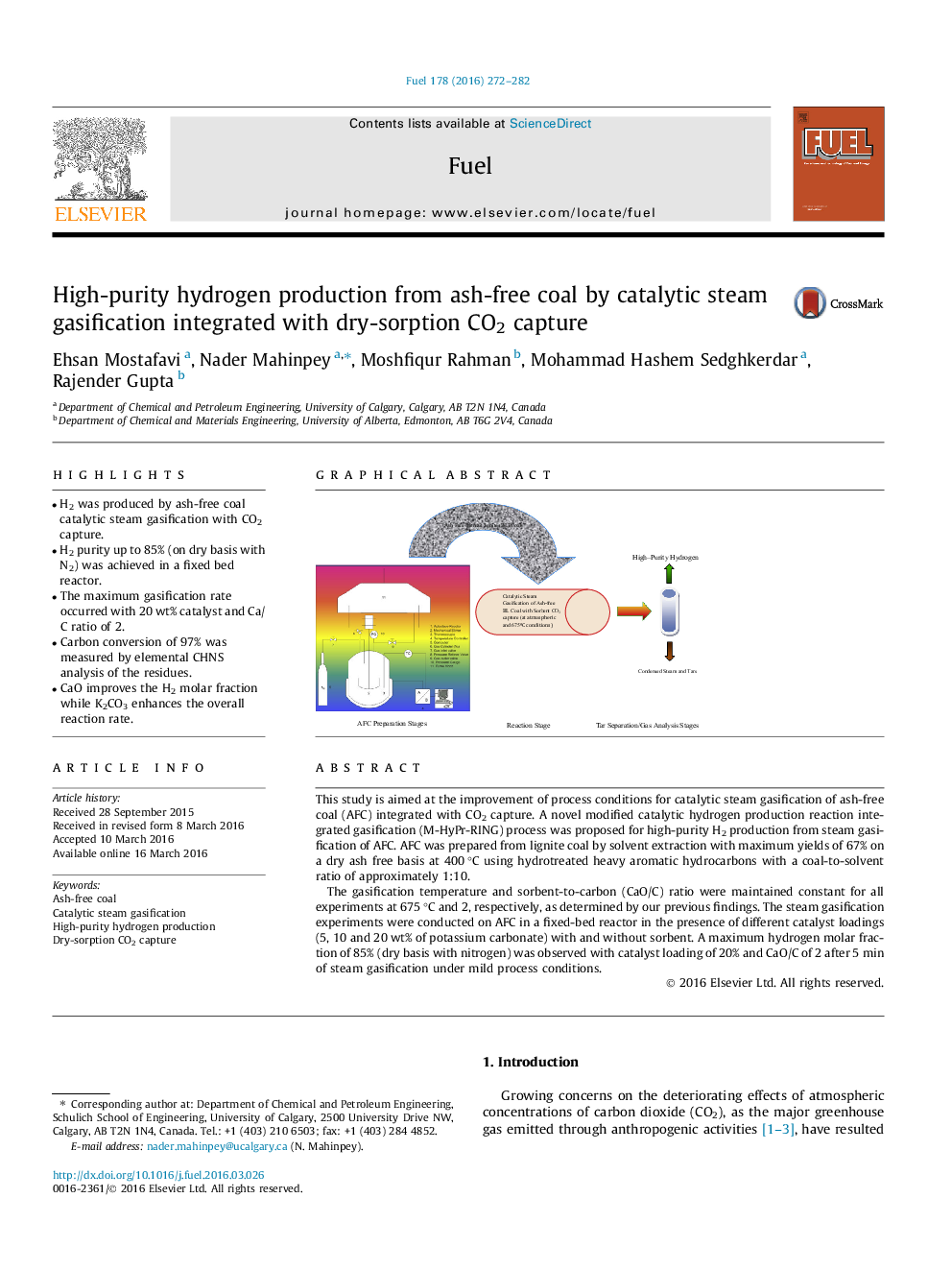

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide