| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205154 | Fuel | 2016 | 8 Pages |

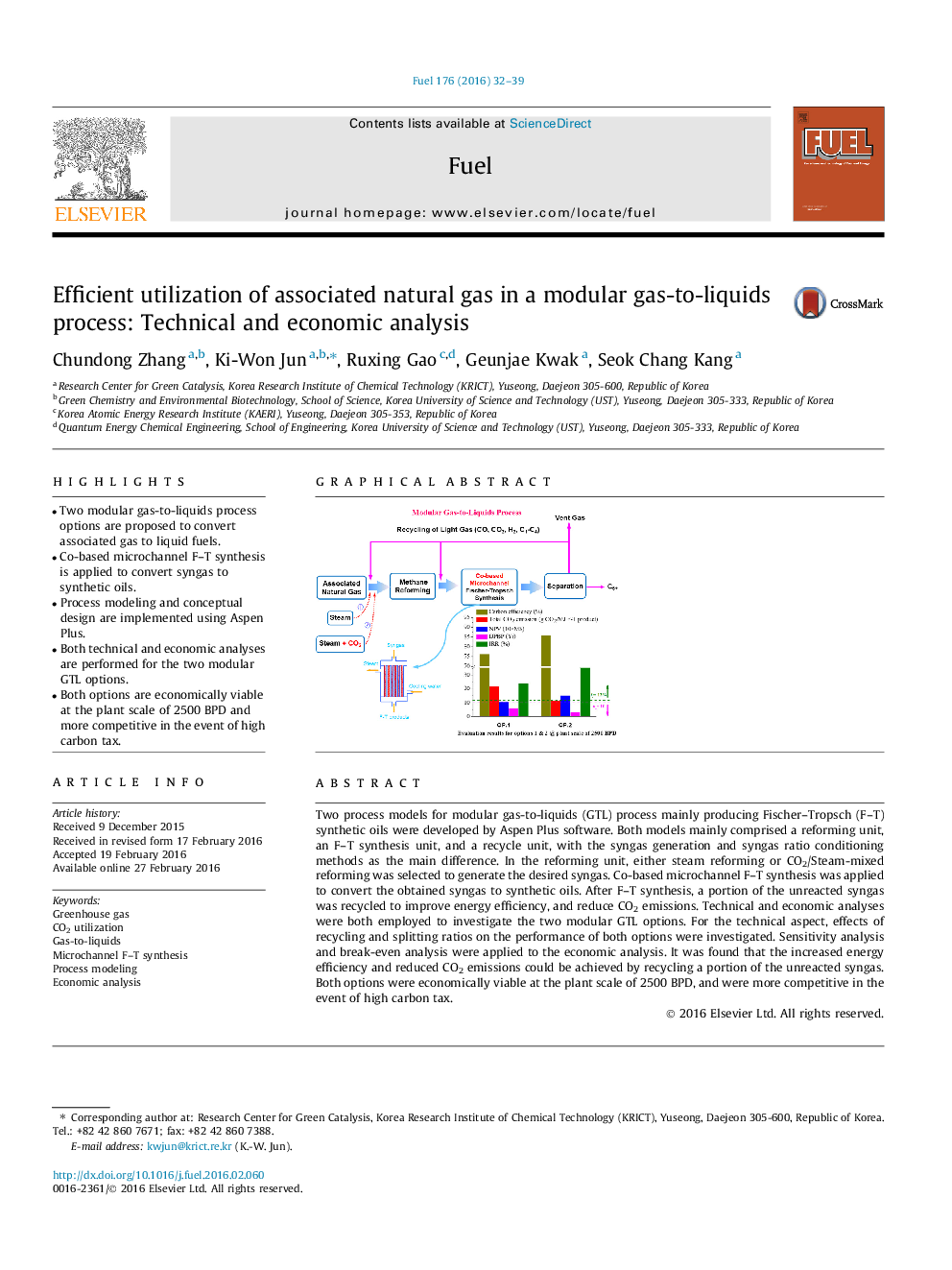

•Two modular gas-to-liquids process options are proposed to convert associated gas to liquid fuels.•Co-based microchannel F–T synthesis is applied to convert syngas to synthetic oils.•Process modeling and conceptual design are implemented using Aspen Plus.•Both technical and economic analyses are performed for the two modular GTL options.•Both options are economically viable at the plant scale of 2500 BPD and more competitive in the event of high carbon tax.

Two process models for modular gas-to-liquids (GTL) process mainly producing Fischer–Tropsch (F–T) synthetic oils were developed by Aspen Plus software. Both models mainly comprised a reforming unit, an F–T synthesis unit, and a recycle unit, with the syngas generation and syngas ratio conditioning methods as the main difference. In the reforming unit, either steam reforming or CO2/Steam-mixed reforming was selected to generate the desired syngas. Co-based microchannel F–T synthesis was applied to convert the obtained syngas to synthetic oils. After F–T synthesis, a portion of the unreacted syngas was recycled to improve energy efficiency, and reduce CO2 emissions. Technical and economic analyses were both employed to investigate the two modular GTL options. For the technical aspect, effects of recycling and splitting ratios on the performance of both options were investigated. Sensitivity analysis and break-even analysis were applied to the economic analysis. It was found that the increased energy efficiency and reduced CO2 emissions could be achieved by recycling a portion of the unreacted syngas. Both options were economically viable at the plant scale of 2500 BPD, and were more competitive in the event of high carbon tax.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide