| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205213 | Fuel | 2016 | 10 Pages |

•Reaction of glycerol with tert-butyl alcohol and acetone in flow reactor.•Zeolite-BEA converts glycerol completely into the mixture of solketal and STBE.•Yield of STBE in 1-mono-GTBE ketalisation depends inversely from temperature.•The introduction of solketal into hydrocarbon oil improves its antiwear properties.•Solketal is the most effective antiwear agent from all the ethers formed.

Glycerol alkylation with tert-butyl alcohol and ketalisation of glycerol 1-mono-tert-butyl ether with acetone, as well as the combined ketalisation–alkylation process, has been studied in a fixed-bed flow reactor. It has been shown that a continuous, one-step process for the quantitative conversion of glycerol into a mixture of ethers can be accomplished under mild conditions (atmospheric pressure and temperatures of 40–70 °C) over a zeolite BEA catalyst. Furthermore, the effects of the glycerol ether additives on the antiwear properties of low-viscosity base oil have been characterised.

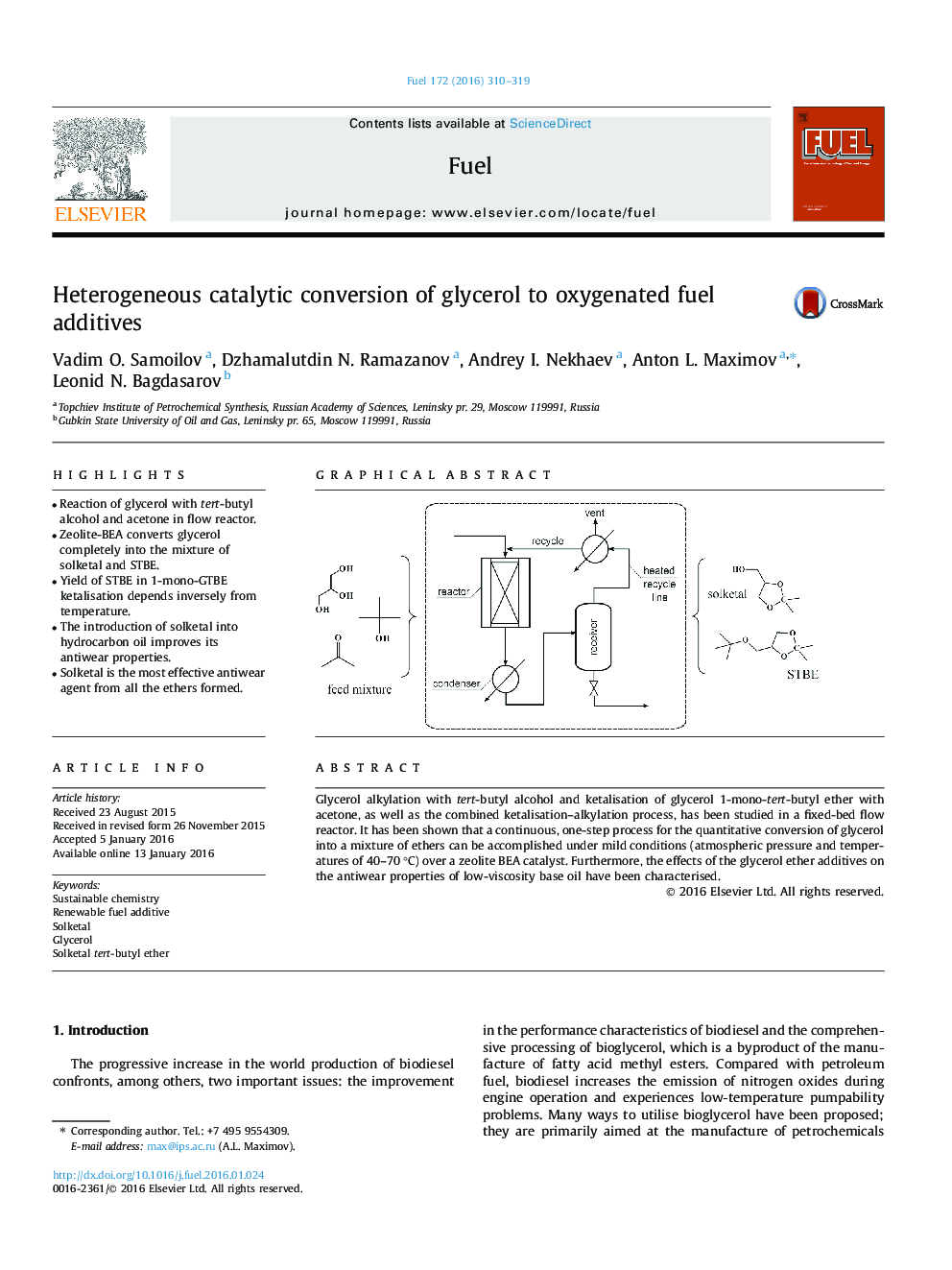

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide