| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205226 | Fuel | 2016 | 9 Pages |

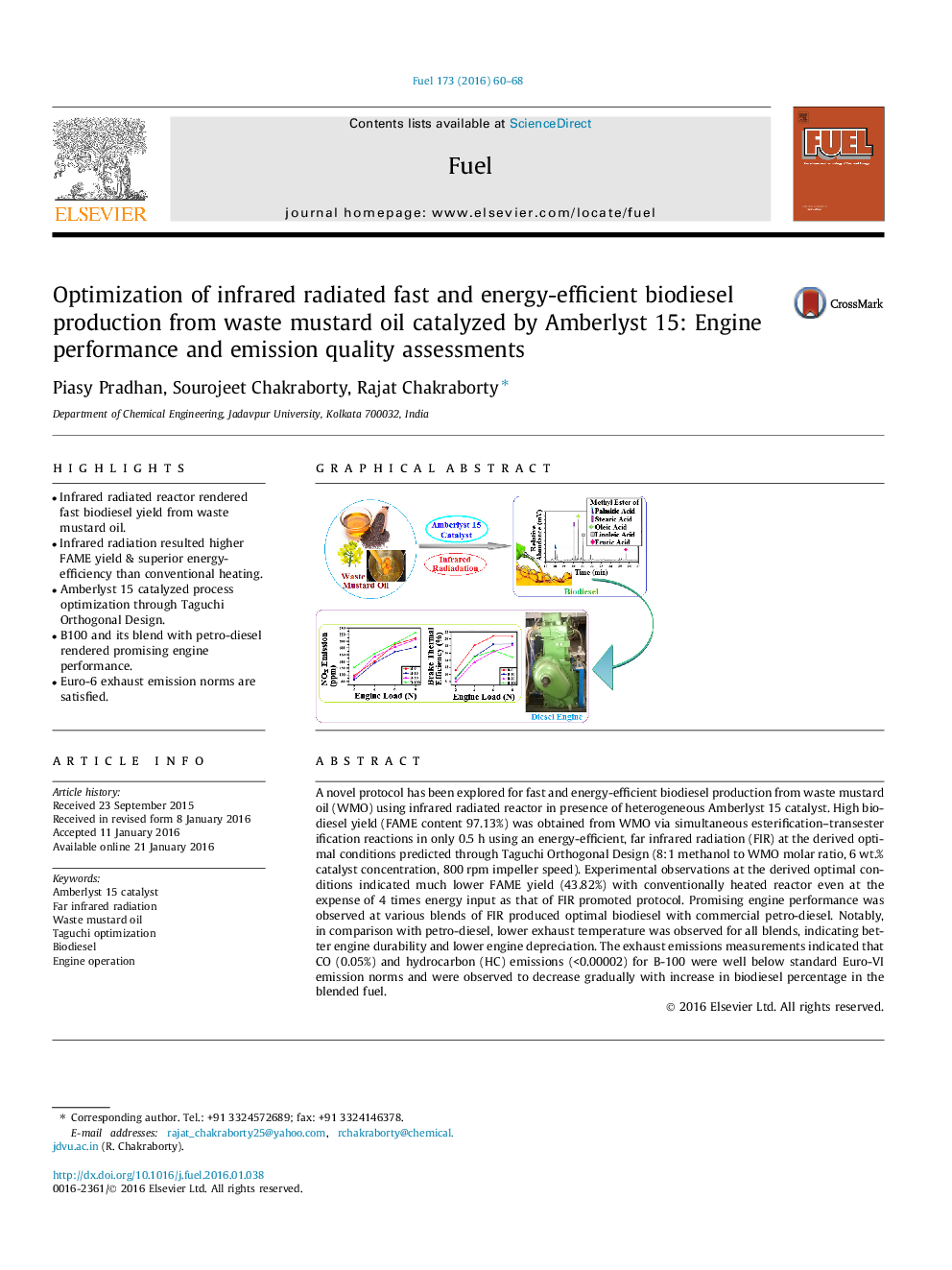

•Infrared radiated reactor rendered fast biodiesel yield from waste mustard oil.•Infrared radiation resulted higher FAME yield & superior energy-efficiency than conventional heating.•Amberlyst 15 catalyzed process optimization through Taguchi Orthogonal Design.•B100 and its blend with petro-diesel rendered promising engine performance.•Euro-6 exhaust emission norms are satisfied.

A novel protocol has been explored for fast and energy-efficient biodiesel production from waste mustard oil (WMO) using infrared radiated reactor in presence of heterogeneous Amberlyst 15 catalyst. High biodiesel yield (FAME content 97.13%) was obtained from WMO via simultaneous esterification–transesterification reactions in only 0.5 h using an energy-efficient, far infrared radiation (FIR) at the derived optimal conditions predicted through Taguchi Orthogonal Design (8:1 methanol to WMO molar ratio, 6 wt.% catalyst concentration, 800 rpm impeller speed). Experimental observations at the derived optimal conditions indicated much lower FAME yield (43.82%) with conventionally heated reactor even at the expense of 4 times energy input as that of FIR promoted protocol. Promising engine performance was observed at various blends of FIR produced optimal biodiesel with commercial petro-diesel. Notably, in comparison with petro-diesel, lower exhaust temperature was observed for all blends, indicating better engine durability and lower engine depreciation. The exhaust emissions measurements indicated that CO (0.05%) and hydrocarbon (HC) emissions (<0.00002) for B-100 were well below standard Euro-VI emission norms and were observed to decrease gradually with increase in biodiesel percentage in the blended fuel.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide