| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205279 | Fuel | 2016 | 7 Pages |

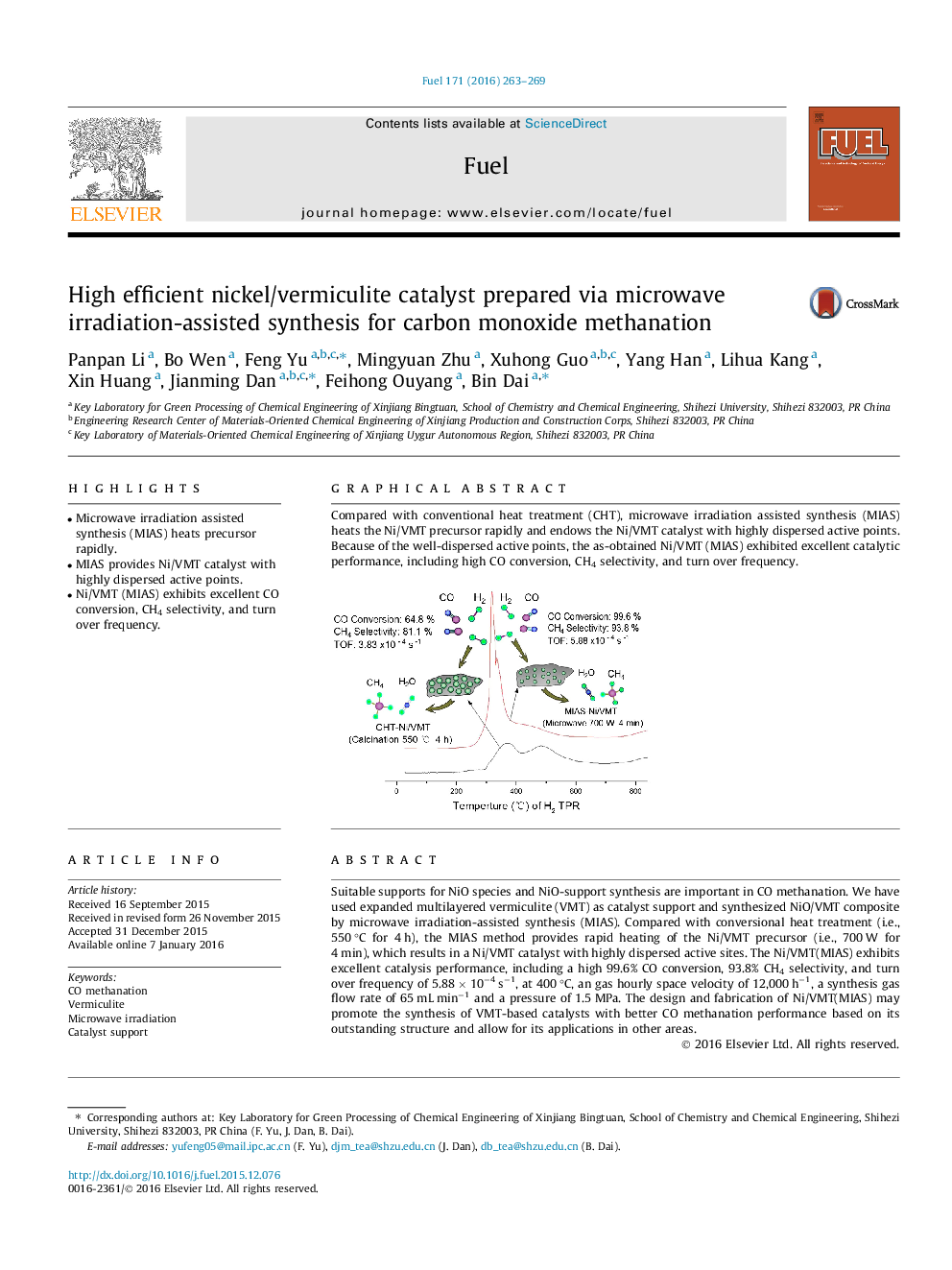

•Microwave irradiation assisted synthesis (MIAS) heats precursor rapidly.•MIAS provides Ni/VMT catalyst with highly dispersed active points.•Ni/VMT (MIAS) exhibits excellent CO conversion, CH4 selectivity, and turn over frequency.

Suitable supports for NiO species and NiO-support synthesis are important in CO methanation. We have used expanded multilayered vermiculite (VMT) as catalyst support and synthesized NiO/VMT composite by microwave irradiation-assisted synthesis (MIAS). Compared with conversional heat treatment (i.e., 550 °C for 4 h), the MIAS method provides rapid heating of the Ni/VMT precursor (i.e., 700 W for 4 min), which results in a Ni/VMT catalyst with highly dispersed active sites. The Ni/VMT(MIAS) exhibits excellent catalysis performance, including a high 99.6% CO conversion, 93.8% CH4 selectivity, and turn over frequency of 5.88 × 10−4 s−1, at 400 °C, an gas hourly space velocity of 12,000 h−1, a synthesis gas flow rate of 65 mL min−1 and a pressure of 1.5 MPa. The design and fabrication of Ni/VMT(MIAS) may promote the synthesis of VMT-based catalysts with better CO methanation performance based on its outstanding structure and allow for its applications in other areas.

Graphical abstractCompared with conventional heat treatment (CHT), microwave irradiation assisted synthesis (MIAS) heats the Ni/VMT precursor rapidly and endows the Ni/VMT catalyst with highly dispersed active points. Because of the well-dispersed active points, the as-obtained Ni/VMT (MIAS) exhibited excellent catalytic performance, including high CO conversion, CH4 selectivity, and turn over frequency.Figure optionsDownload full-size imageDownload as PowerPoint slide