| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205431 | Fuel | 2015 | 7 Pages |

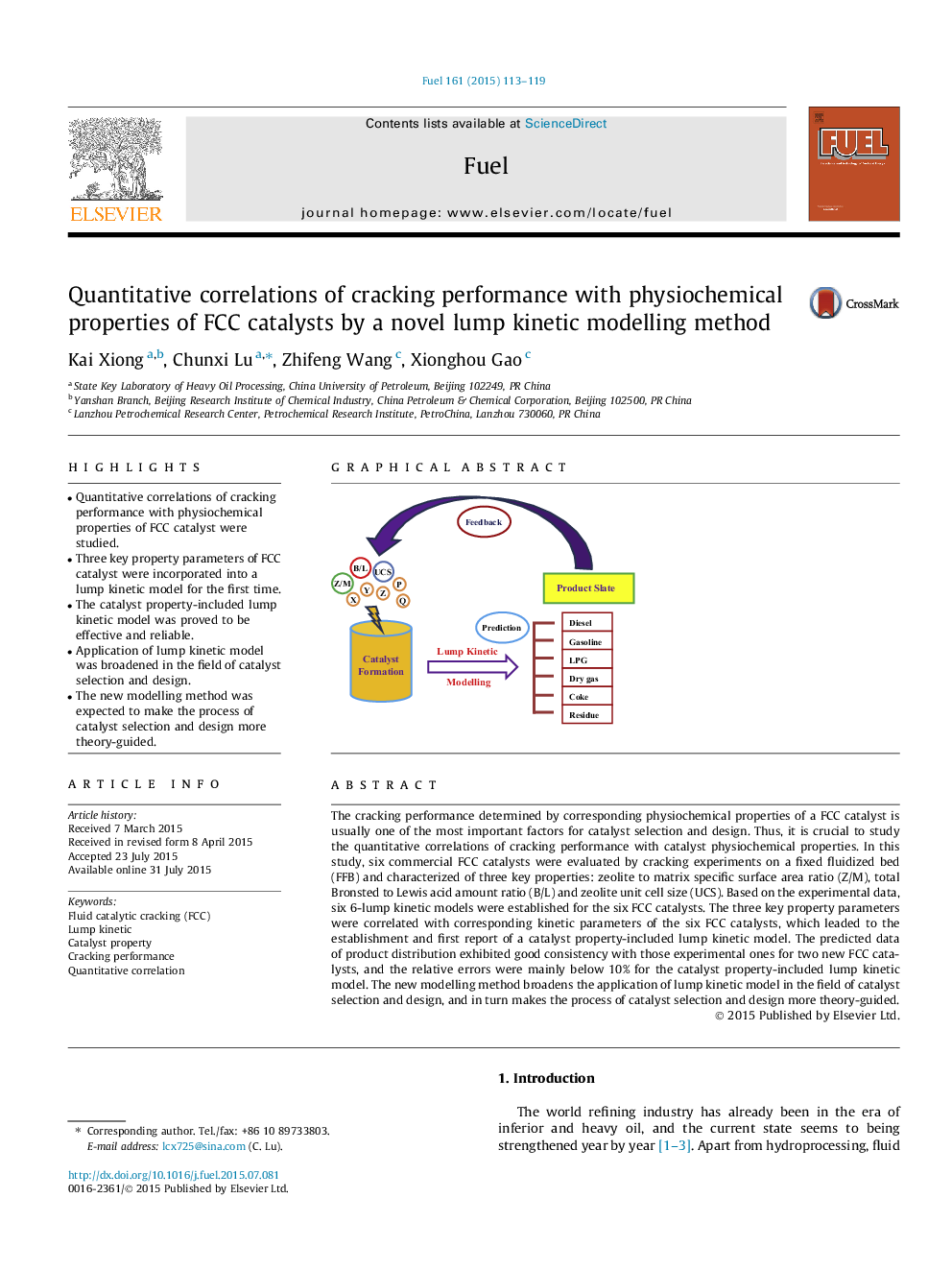

•Quantitative correlations of cracking performance with physiochemical properties of FCC catalyst were studied.•Three key property parameters of FCC catalyst were incorporated into a lump kinetic model for the first time.•The catalyst property-included lump kinetic model was proved to be effective and reliable.•Application of lump kinetic model was broadened in the field of catalyst selection and design.•The new modelling method was expected to make the process of catalyst selection and design more theory-guided.

The cracking performance determined by corresponding physiochemical properties of a FCC catalyst is usually one of the most important factors for catalyst selection and design. Thus, it is crucial to study the quantitative correlations of cracking performance with catalyst physiochemical properties. In this study, six commercial FCC catalysts were evaluated by cracking experiments on a fixed fluidized bed (FFB) and characterized of three key properties: zeolite to matrix specific surface area ratio (Z/M), total Bronsted to Lewis acid amount ratio (B/L) and zeolite unit cell size (UCS). Based on the experimental data, six 6-lump kinetic models were established for the six FCC catalysts. The three key property parameters were correlated with corresponding kinetic parameters of the six FCC catalysts, which leaded to the establishment and first report of a catalyst property-included lump kinetic model. The predicted data of product distribution exhibited good consistency with those experimental ones for two new FCC catalysts, and the relative errors were mainly below 10% for the catalyst property-included lump kinetic model. The new modelling method broadens the application of lump kinetic model in the field of catalyst selection and design, and in turn makes the process of catalyst selection and design more theory-guided.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide