| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205598 | Fuel | 2015 | 8 Pages |

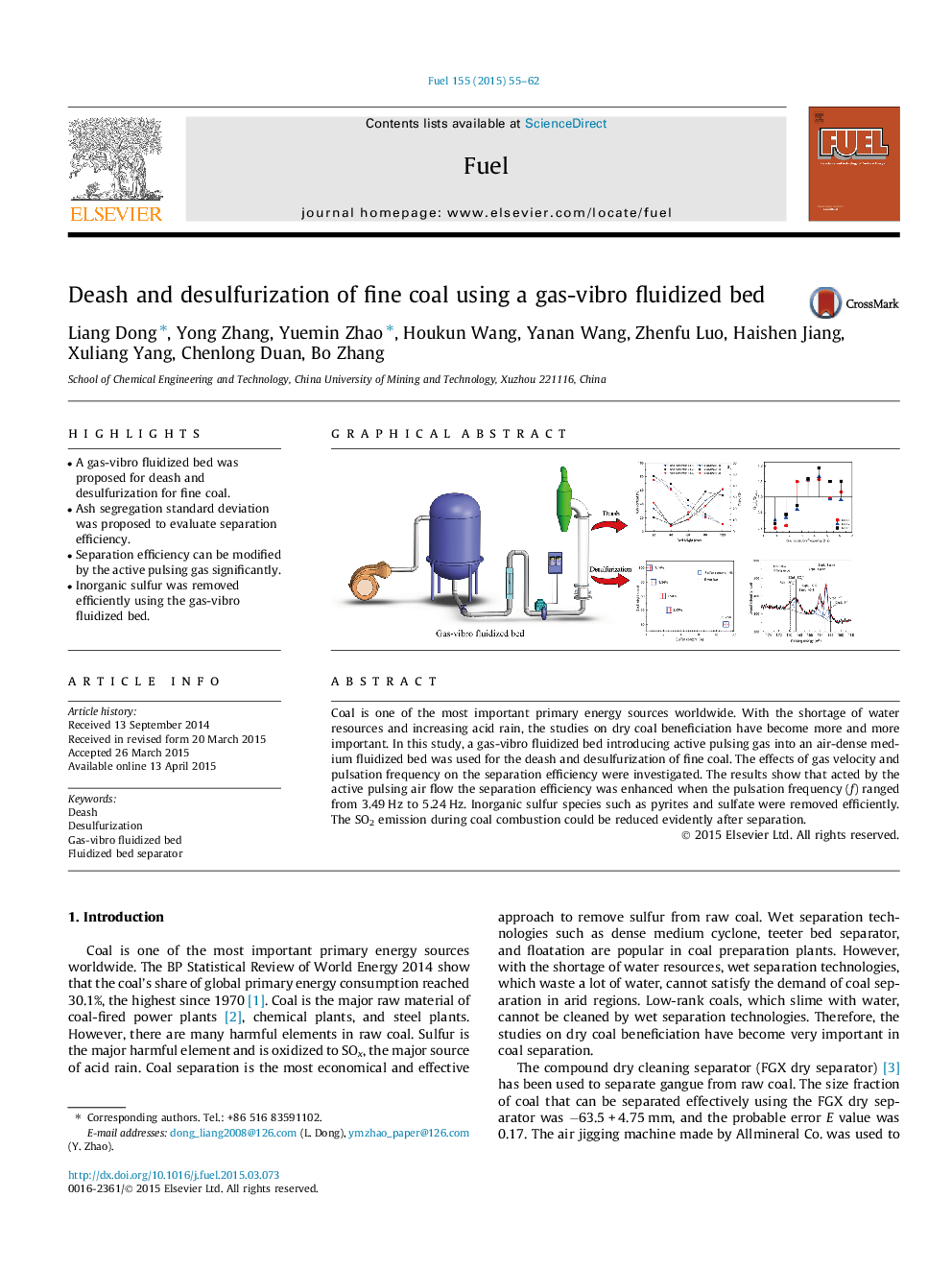

•A gas-vibro fluidized bed was proposed for deash and desulfurization for fine coal.•Ash segregation standard deviation was proposed to evaluate separation efficiency.•Separation efficiency can be modified by the active pulsing gas significantly.•Inorganic sulfur was removed efficiently using the gas-vibro fluidized bed.

Coal is one of the most important primary energy sources worldwide. With the shortage of water resources and increasing acid rain, the studies on dry coal beneficiation have become more and more important. In this study, a gas-vibro fluidized bed introducing active pulsing gas into an air-dense medium fluidized bed was used for the deash and desulfurization of fine coal. The effects of gas velocity and pulsation frequency on the separation efficiency were investigated. The results show that acted by the active pulsing air flow the separation efficiency was enhanced when the pulsation frequency (f) ranged from 3.49 Hz to 5.24 Hz. Inorganic sulfur species such as pyrites and sulfate were removed efficiently. The SO2 emission during coal combustion could be reduced evidently after separation.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide