| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 205805 | Fuel | 2015 | 12 Pages |

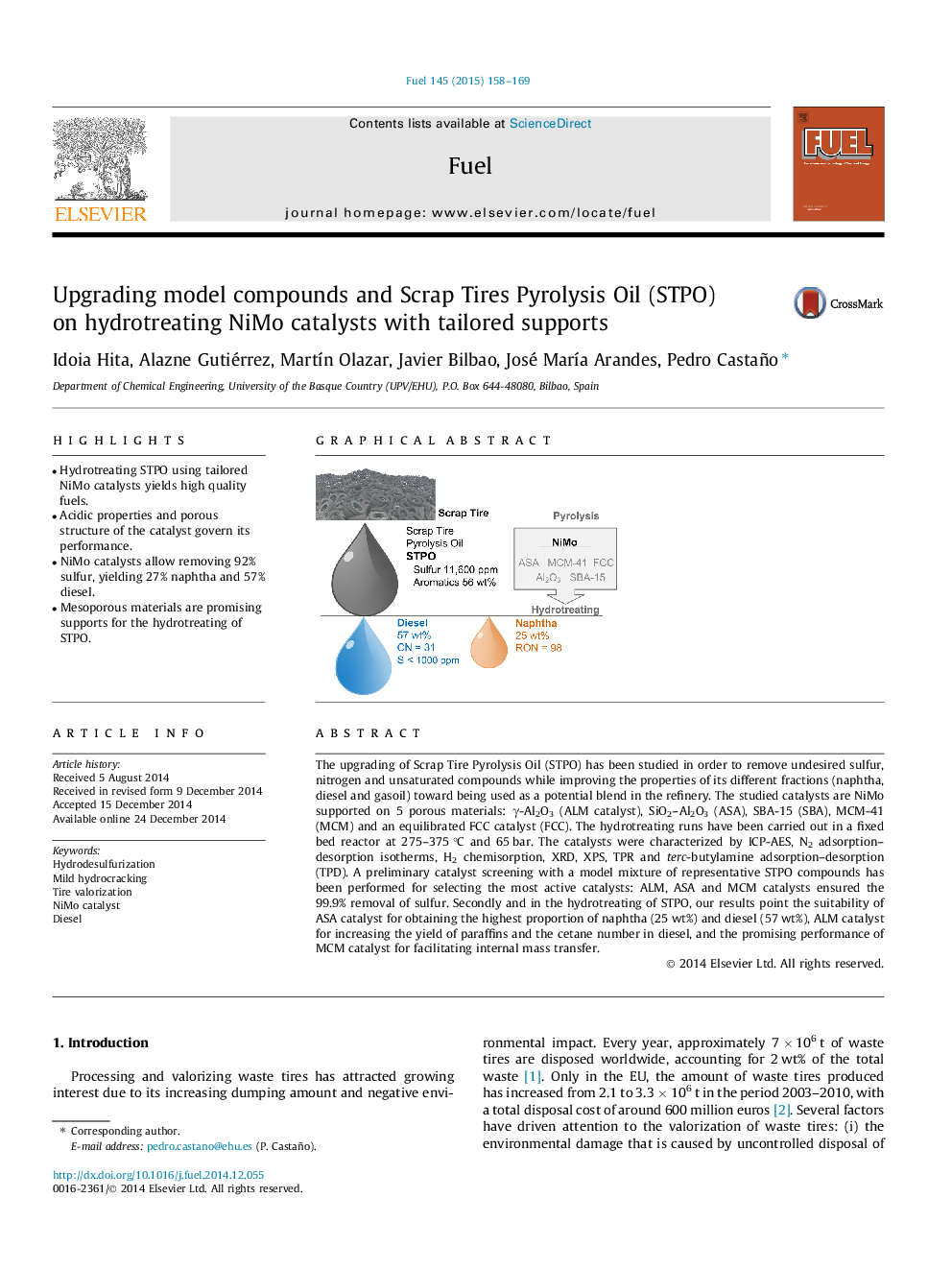

•Hydrotreating STPO using tailored NiMo catalysts yields high quality fuels.•Acidic properties and porous structure of the catalyst govern its performance.•NiMo catalysts allow removing 92% sulfur, yielding 27% naphtha and 57% diesel.•Mesoporous materials are promising supports for the hydrotreating of STPO.

The upgrading of Scrap Tire Pyrolysis Oil (STPO) has been studied in order to remove undesired sulfur, nitrogen and unsaturated compounds while improving the properties of its different fractions (naphtha, diesel and gasoil) toward being used as a potential blend in the refinery. The studied catalysts are NiMo supported on 5 porous materials: γ-Al2O3 (ALM catalyst), SiO2–Al2O3 (ASA), SBA-15 (SBA), MCM-41 (MCM) and an equilibrated FCC catalyst (FCC). The hydrotreating runs have been carried out in a fixed bed reactor at 275–375 °C and 65 bar. The catalysts were characterized by ICP-AES, N2 adsorption–desorption isotherms, H2 chemisorption, XRD, XPS, TPR and terc-butylamine adsorption–desorption (TPD). A preliminary catalyst screening with a model mixture of representative STPO compounds has been performed for selecting the most active catalysts: ALM, ASA and MCM catalysts ensured the 99.9% removal of sulfur. Secondly and in the hydrotreating of STPO, our results point the suitability of ASA catalyst for obtaining the highest proportion of naphtha (25 wt%) and diesel (57 wt%), ALM catalyst for increasing the yield of paraffins and the cetane number in diesel, and the promising performance of MCM catalyst for facilitating internal mass transfer.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide