| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 206003 | Fuel | 2014 | 7 Pages |

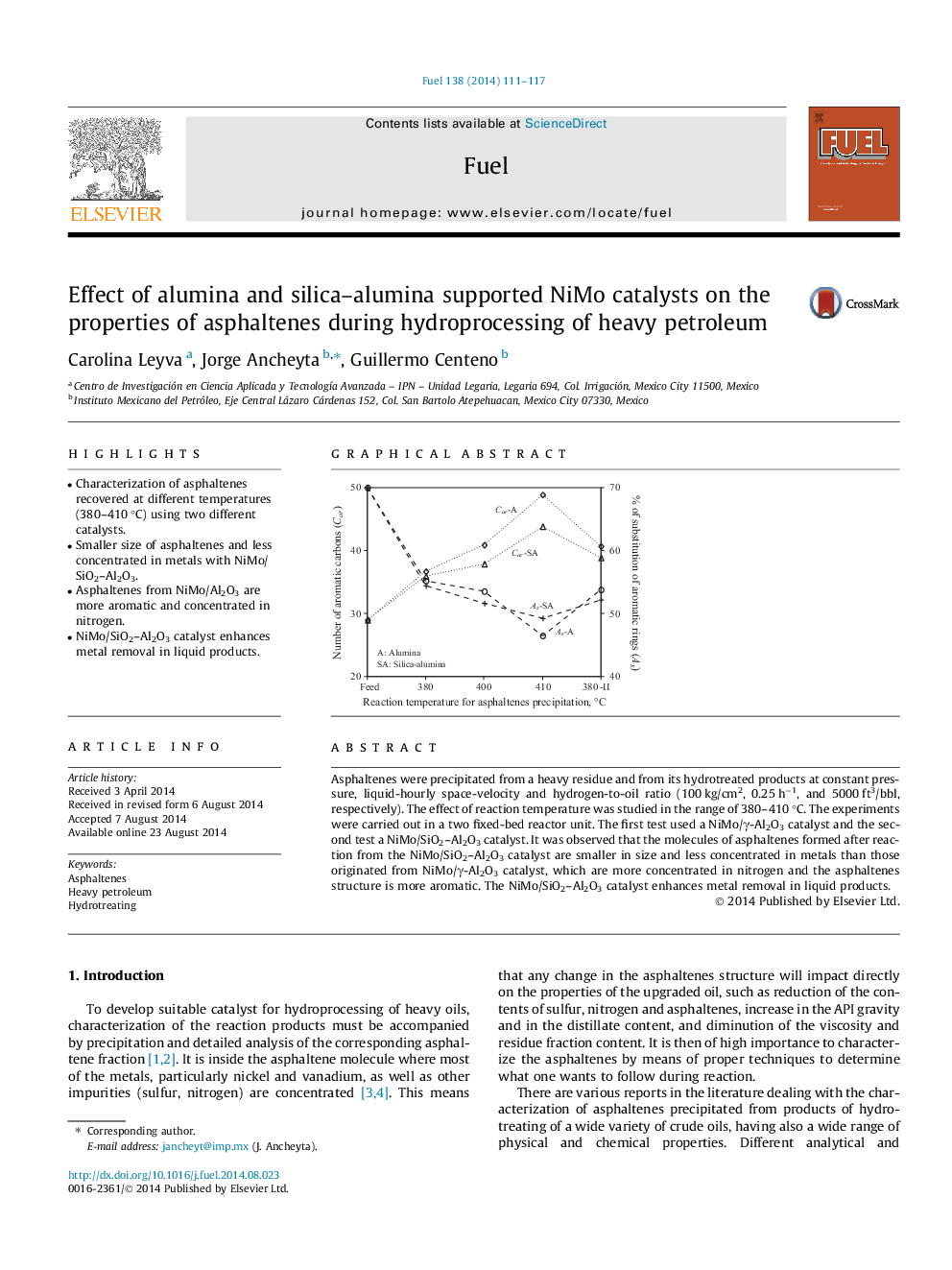

•Characterization of asphaltenes recovered at different temperatures (380–410 °C) using two different catalysts.•Smaller size of asphaltenes and less concentrated in metals with NiMo/SiO2–Al2O3.•Asphaltenes from NiMo/Al2O3 are more aromatic and concentrated in nitrogen.•NiMo/SiO2–Al2O3 catalyst enhances metal removal in liquid products.

Asphaltenes were precipitated from a heavy residue and from its hydrotreated products at constant pressure, liquid-hourly space-velocity and hydrogen-to-oil ratio (100 kg/cm2, 0.25 h−1, and 5000 ft3/bbl, respectively). The effect of reaction temperature was studied in the range of 380–410 °C. The experiments were carried out in a two fixed-bed reactor unit. The first test used a NiMo/γ-Al2O3 catalyst and the second test a NiMo/SiO2–Al2O3 catalyst. It was observed that the molecules of asphaltenes formed after reaction from the NiMo/SiO2–Al2O3 catalyst are smaller in size and less concentrated in metals than those originated from NiMo/γ-Al2O3 catalyst, which are more concentrated in nitrogen and the asphaltenes structure is more aromatic. The NiMo/SiO2–Al2O3 catalyst enhances metal removal in liquid products.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide