| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 206044 | Fuel | 2014 | 8 Pages |

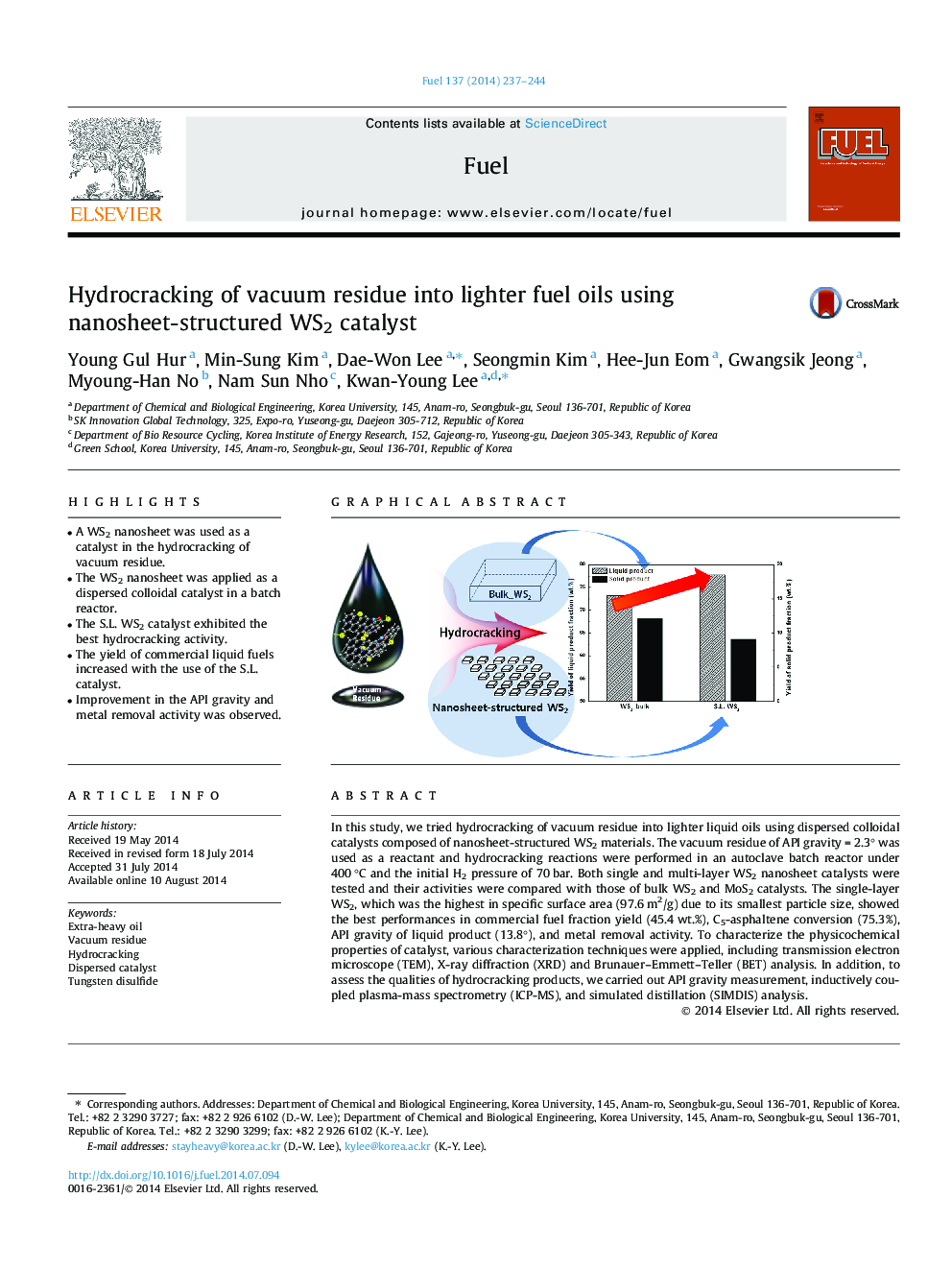

•A WS2 nanosheet was used as a catalyst in the hydrocracking of vacuum residue.•The WS2 nanosheet was applied as a dispersed colloidal catalyst in a batch reactor.•The S.L. WS2 catalyst exhibited the best hydrocracking activity.•The yield of commercial liquid fuels increased with the use of the S.L. catalyst.•Improvement in the API gravity and metal removal activity was observed.

In this study, we tried hydrocracking of vacuum residue into lighter liquid oils using dispersed colloidal catalysts composed of nanosheet-structured WS2 materials. The vacuum residue of API gravity = 2.3° was used as a reactant and hydrocracking reactions were performed in an autoclave batch reactor under 400 °C and the initial H2 pressure of 70 bar. Both single and multi-layer WS2 nanosheet catalysts were tested and their activities were compared with those of bulk WS2 and MoS2 catalysts. The single-layer WS2, which was the highest in specific surface area (97.6 m2/g) due to its smallest particle size, showed the best performances in commercial fuel fraction yield (45.4 wt.%), C5-asphaltene conversion (75.3%), API gravity of liquid product (13.8°), and metal removal activity. To characterize the physicochemical properties of catalyst, various characterization techniques were applied, including transmission electron microscope (TEM), X-ray diffraction (XRD) and Brunauer–Emmett–Teller (BET) analysis. In addition, to assess the qualities of hydrocracking products, we carried out API gravity measurement, inductively coupled plasma-mass spectrometry (ICP-MS), and simulated distillation (SIMDIS) analysis.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide