| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 206264 | Fuel | 2014 | 17 Pages |

•A novel rotary reactor has been proposed for CLC with carbon separation.•The design is compact, stable, and it captures CO2 with minimum energy penalty.•The fundamentals of OC, reactor design, and operating conditions have been studied.•The key parameters for the reaction kinetics have been evaluated by simple models.•A systematic procedure has been proposed for reactor design and optimization.

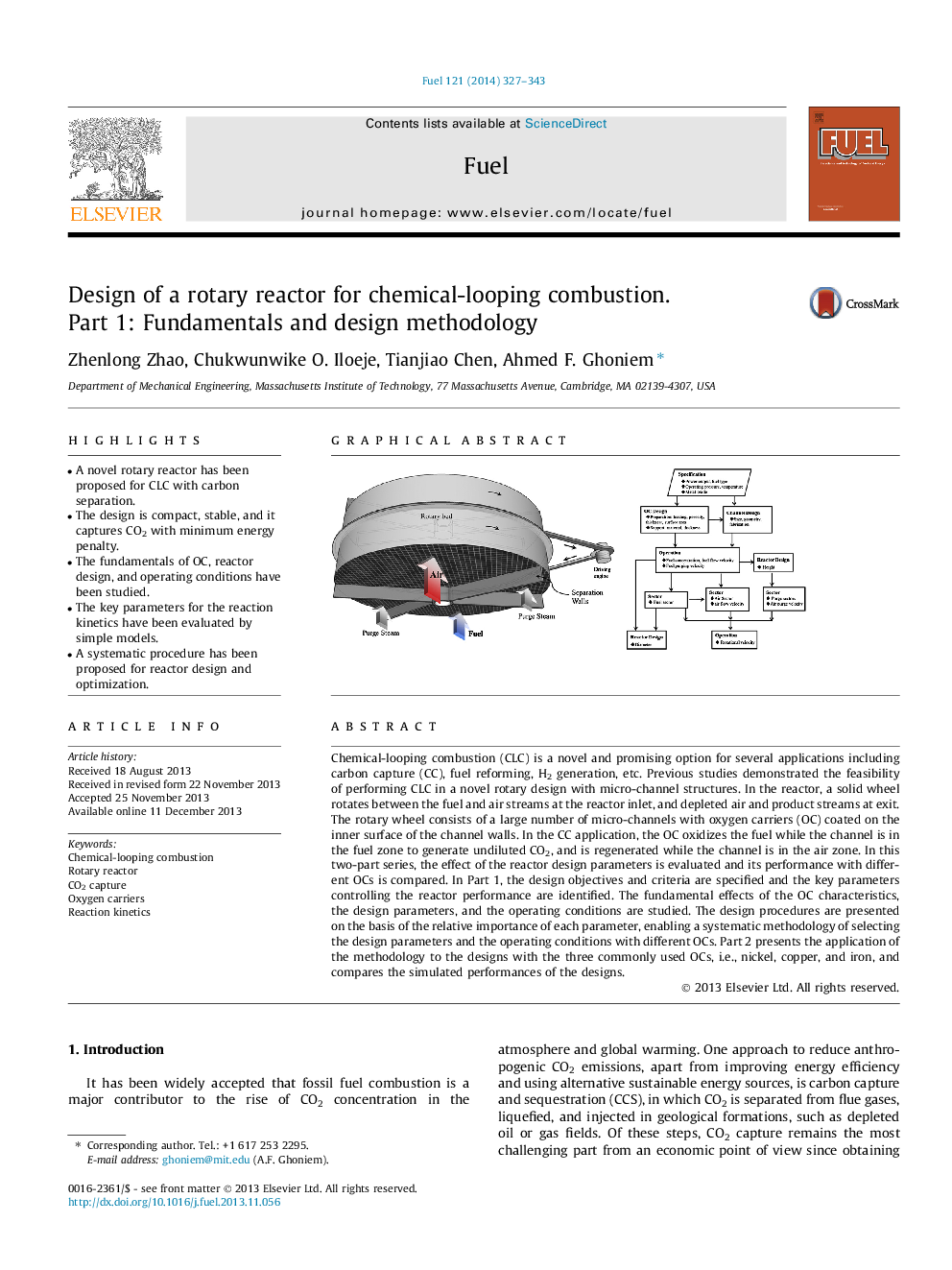

Chemical-looping combustion (CLC) is a novel and promising option for several applications including carbon capture (CC), fuel reforming, H2 generation, etc. Previous studies demonstrated the feasibility of performing CLC in a novel rotary design with micro-channel structures. In the reactor, a solid wheel rotates between the fuel and air streams at the reactor inlet, and depleted air and product streams at exit. The rotary wheel consists of a large number of micro-channels with oxygen carriers (OC) coated on the inner surface of the channel walls. In the CC application, the OC oxidizes the fuel while the channel is in the fuel zone to generate undiluted CO2, and is regenerated while the channel is in the air zone. In this two-part series, the effect of the reactor design parameters is evaluated and its performance with different OCs is compared. In Part 1, the design objectives and criteria are specified and the key parameters controlling the reactor performance are identified. The fundamental effects of the OC characteristics, the design parameters, and the operating conditions are studied. The design procedures are presented on the basis of the relative importance of each parameter, enabling a systematic methodology of selecting the design parameters and the operating conditions with different OCs. Part 2 presents the application of the methodology to the designs with the three commonly used OCs, i.e., nickel, copper, and iron, and compares the simulated performances of the designs.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide