| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 255985 | Construction and Building Materials | 2016 | 10 Pages |

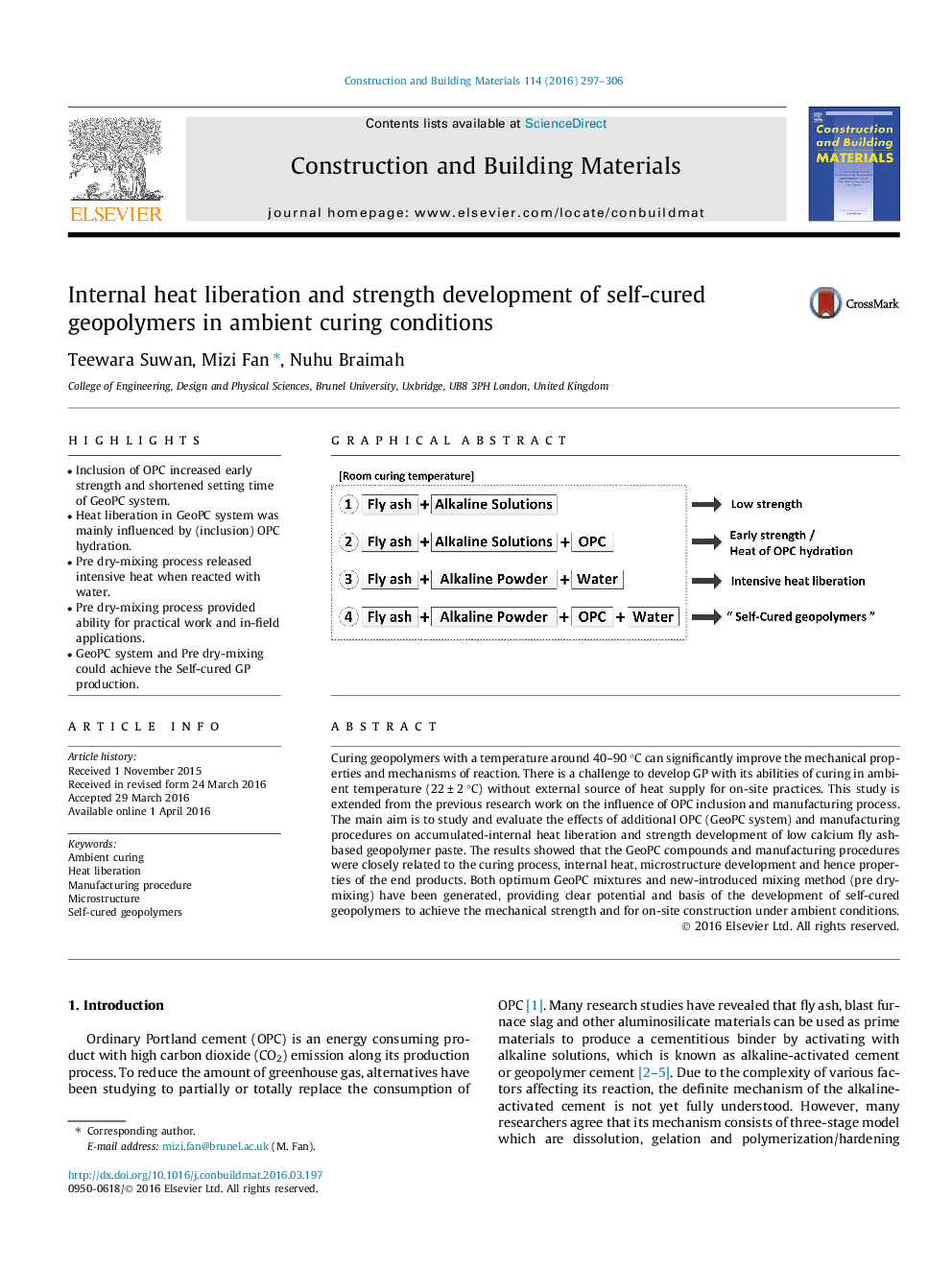

•Inclusion of OPC increased early strength and shortened setting time of GeoPC system.•Heat liberation in GeoPC system was mainly influenced by (inclusion) OPC hydration.•Pre dry-mixing process released intensive heat when reacted with water.•Pre dry-mixing process provided ability for practical work and in-field applications.•GeoPC system and Pre dry-mixing could achieve the Self-cured GP production.

Curing geopolymers with a temperature around 40–90 °C can significantly improve the mechanical properties and mechanisms of reaction. There is a challenge to develop GP with its abilities of curing in ambient temperature (22 ± 2 °C) without external source of heat supply for on-site practices. This study is extended from the previous research work on the influence of OPC inclusion and manufacturing process. The main aim is to study and evaluate the effects of additional OPC (GeoPC system) and manufacturing procedures on accumulated-internal heat liberation and strength development of low calcium fly ash-based geopolymer paste. The results showed that the GeoPC compounds and manufacturing procedures were closely related to the curing process, internal heat, microstructure development and hence properties of the end products. Both optimum GeoPC mixtures and new-introduced mixing method (pre dry-mixing) have been generated, providing clear potential and basis of the development of self-cured geopolymers to achieve the mechanical strength and for on-site construction under ambient conditions.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide