| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 256152 | Construction and Building Materials | 2016 | 9 Pages |

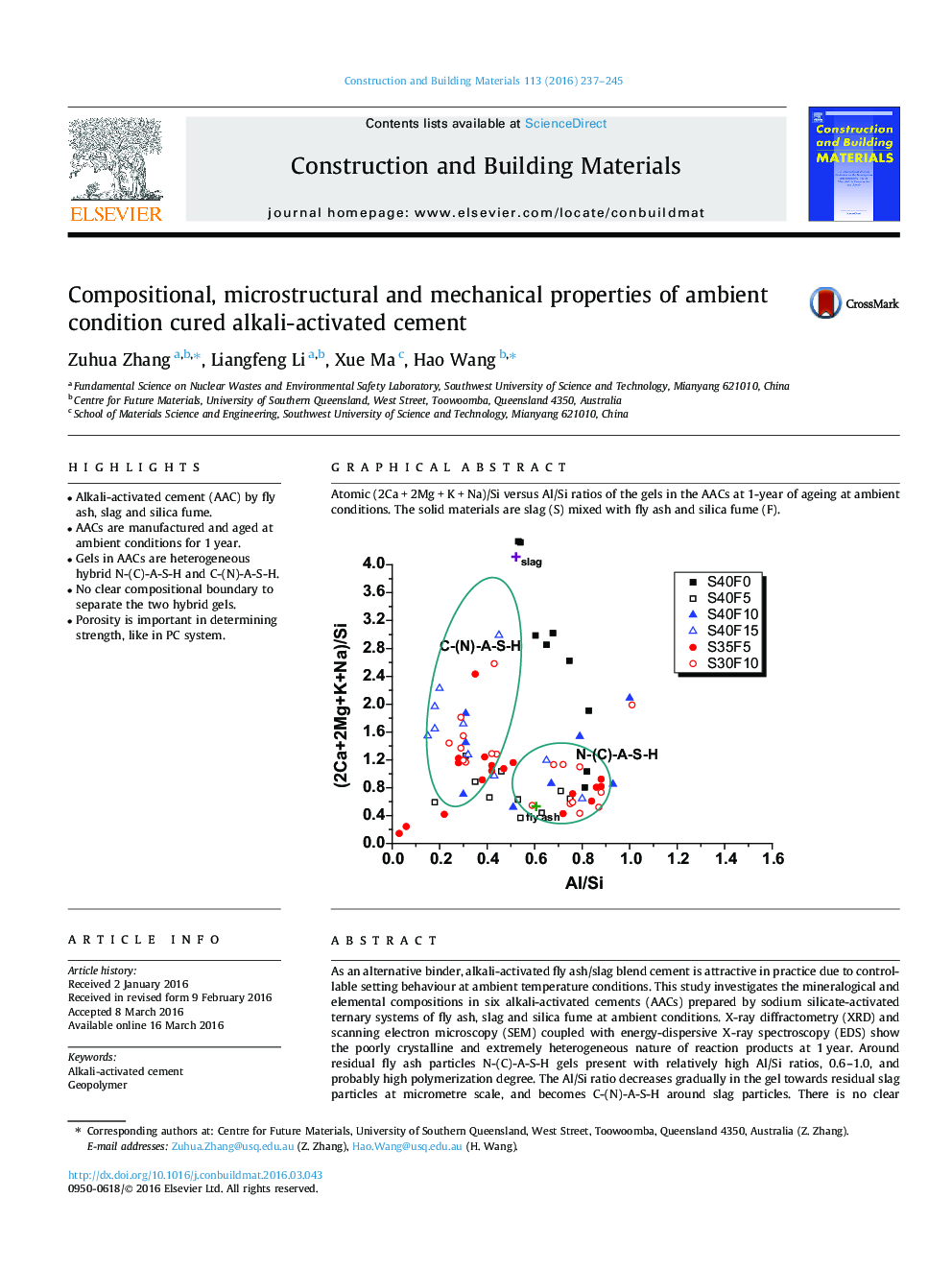

•Alkali-activated cement (AAC) by fly ash, slag and silica fume.•AACs are manufactured and aged at ambient conditions for 1 year.•Gels in AACs are heterogeneous hybrid N-(C)-A-S-H and C-(N)-A-S-H.•No clear compositional boundary to separate the two hybrid gels.•Porosity is important in determining strength, like in PC system.

As an alternative binder, alkali-activated fly ash/slag blend cement is attractive in practice due to controllable setting behaviour at ambient temperature conditions. This study investigates the mineralogical and elemental compositions in six alkali-activated cements (AACs) prepared by sodium silicate-activated ternary systems of fly ash, slag and silica fume at ambient conditions. X-ray diffractometry (XRD) and scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) show the poorly crystalline and extremely heterogeneous nature of reaction products at 1 year. Around residual fly ash particles N-(C)-A-S-H gels present with relatively high Al/Si ratios, 0.6–1.0, and probably high polymerization degree. The Al/Si ratio decreases gradually in the gel towards residual slag particles at micrometre scale, and becomes C-(N)-A-S-H around slag particles. There is no clear compositional boundary to separate the two hybrid gels. Comparing with the composition of the gel, the porosity and pore structure are more relative and determining to the compressive strength development of the AACs.

Graphical abstractAtomic (2Ca + 2Mg + K + Na)/Si versus Al/Si ratios of the gels in the AACs at 1-year of ageing at ambient conditions. The solid materials are slag (S) mixed with fly ash and silica fume (F).Figure optionsDownload full-size imageDownload as PowerPoint slide