| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 256493 | Construction and Building Materials | 2016 | 12 Pages |

•All rubberized products exhibited the expected compressive strength reduction.•High crumb rubber percentages showed poor behavior using automated brick machines.•Rubber incorporation involved significant deformations in laboratory and factory trials.•Automated production of rubberized bricks performed better than long hollow blocks.•Economic incentives seem needed to become crumb rubber aggregates profitable.

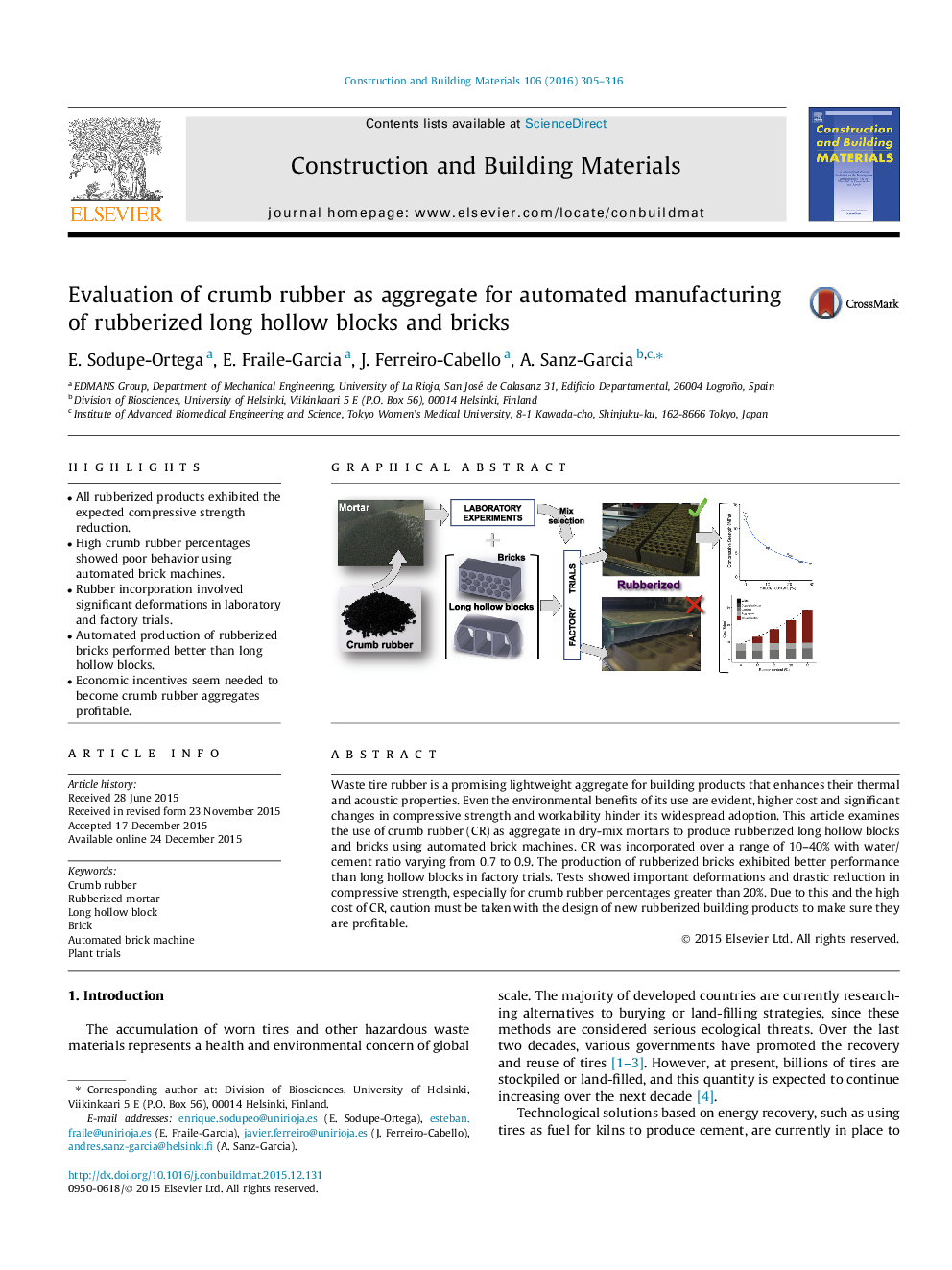

Waste tire rubber is a promising lightweight aggregate for building products that enhances their thermal and acoustic properties. Even the environmental benefits of its use are evident, higher cost and significant changes in compressive strength and workability hinder its widespread adoption. This article examines the use of crumb rubber (CR) as aggregate in dry-mix mortars to produce rubberized long hollow blocks and bricks using automated brick machines. CR was incorporated over a range of 10–40% with water/cement ratio varying from 0.7 to 0.9. The production of rubberized bricks exhibited better performance than long hollow blocks in factory trials. Tests showed important deformations and drastic reduction in compressive strength, especially for crumb rubber percentages greater than 20%. Due to this and the high cost of CR, caution must be taken with the design of new rubberized building products to make sure they are profitable.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide