| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 257103 | Construction and Building Materials | 2015 | 8 Pages |

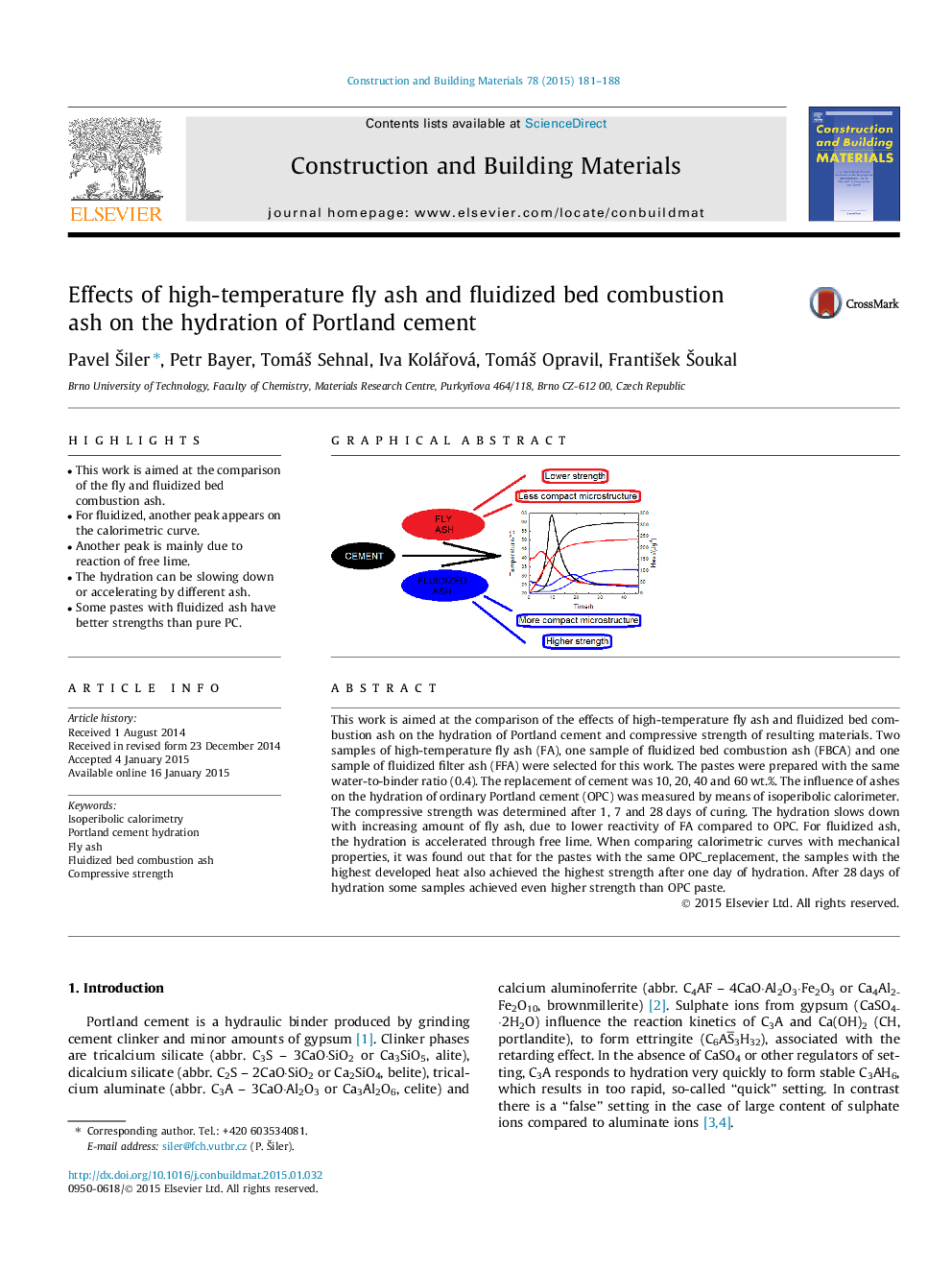

•This work is aimed at the comparison of the fly and fluidized bed combustion ash.•For fluidized, another peak appears on the calorimetric curve.•Another peak is mainly due to reaction of free lime.•The hydration can be slowing down or accelerating by different ash.•Some pastes with fluidized ash have better strengths than pure PC.

This work is aimed at the comparison of the effects of high-temperature fly ash and fluidized bed combustion ash on the hydration of Portland cement and compressive strength of resulting materials. Two samples of high-temperature fly ash (FA), one sample of fluidized bed combustion ash (FBCA) and one sample of fluidized filter ash (FFA) were selected for this work. The pastes were prepared with the same water-to-binder ratio (0.4). The replacement of cement was 10, 20, 40 and 60 wt.%. The influence of ashes on the hydration of ordinary Portland cement (OPC) was measured by means of isoperibolic calorimeter. The compressive strength was determined after 1, 7 and 28 days of curing. The hydration slows down with increasing amount of fly ash, due to lower reactivity of FA compared to OPC. For fluidized ash, the hydration is accelerated through free lime. When comparing calorimetric curves with mechanical properties, it was found out that for the pastes with the same OPC_replacement, the samples with the highest developed heat also achieved the highest strength after one day of hydration. After 28 days of hydration some samples achieved even higher strength than OPC paste.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide