| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 296164 | Nuclear Engineering and Design | 2015 | 9 Pages |

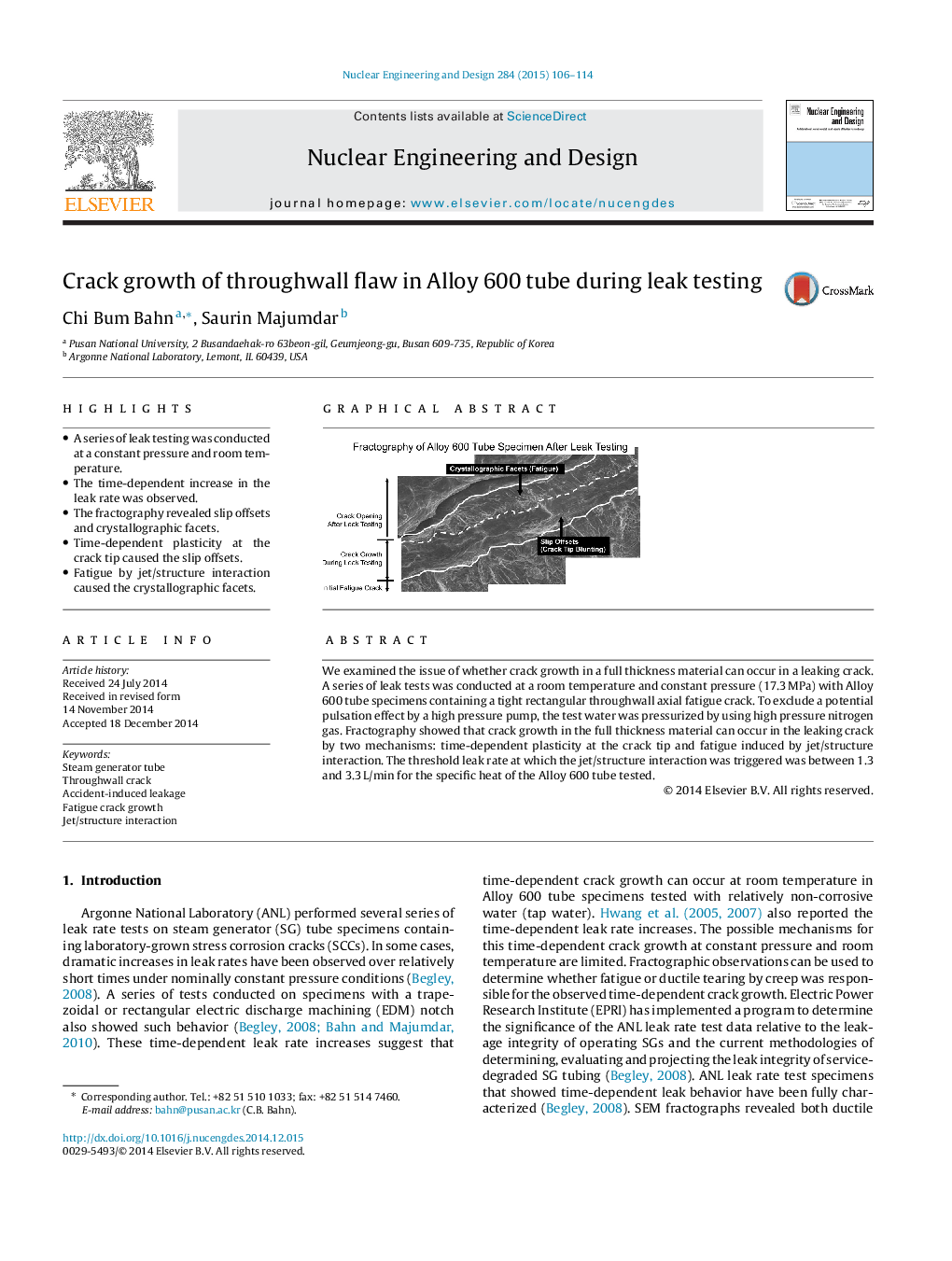

•A series of leak testing was conducted at a constant pressure and room temperature.•The time-dependent increase in the leak rate was observed.•The fractography revealed slip offsets and crystallographic facets.•Time-dependent plasticity at the crack tip caused the slip offsets.•Fatigue by jet/structure interaction caused the crystallographic facets.

We examined the issue of whether crack growth in a full thickness material can occur in a leaking crack. A series of leak tests was conducted at a room temperature and constant pressure (17.3 MPa) with Alloy 600 tube specimens containing a tight rectangular throughwall axial fatigue crack. To exclude a potential pulsation effect by a high pressure pump, the test water was pressurized by using high pressure nitrogen gas. Fractography showed that crack growth in the full thickness material can occur in the leaking crack by two mechanisms: time-dependent plasticity at the crack tip and fatigue induced by jet/structure interaction. The threshold leak rate at which the jet/structure interaction was triggered was between 1.3 and 3.3 L/min for the specific heat of the Alloy 600 tube tested.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide