| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4488346 | Water Research | 2017 | 5 Pages |

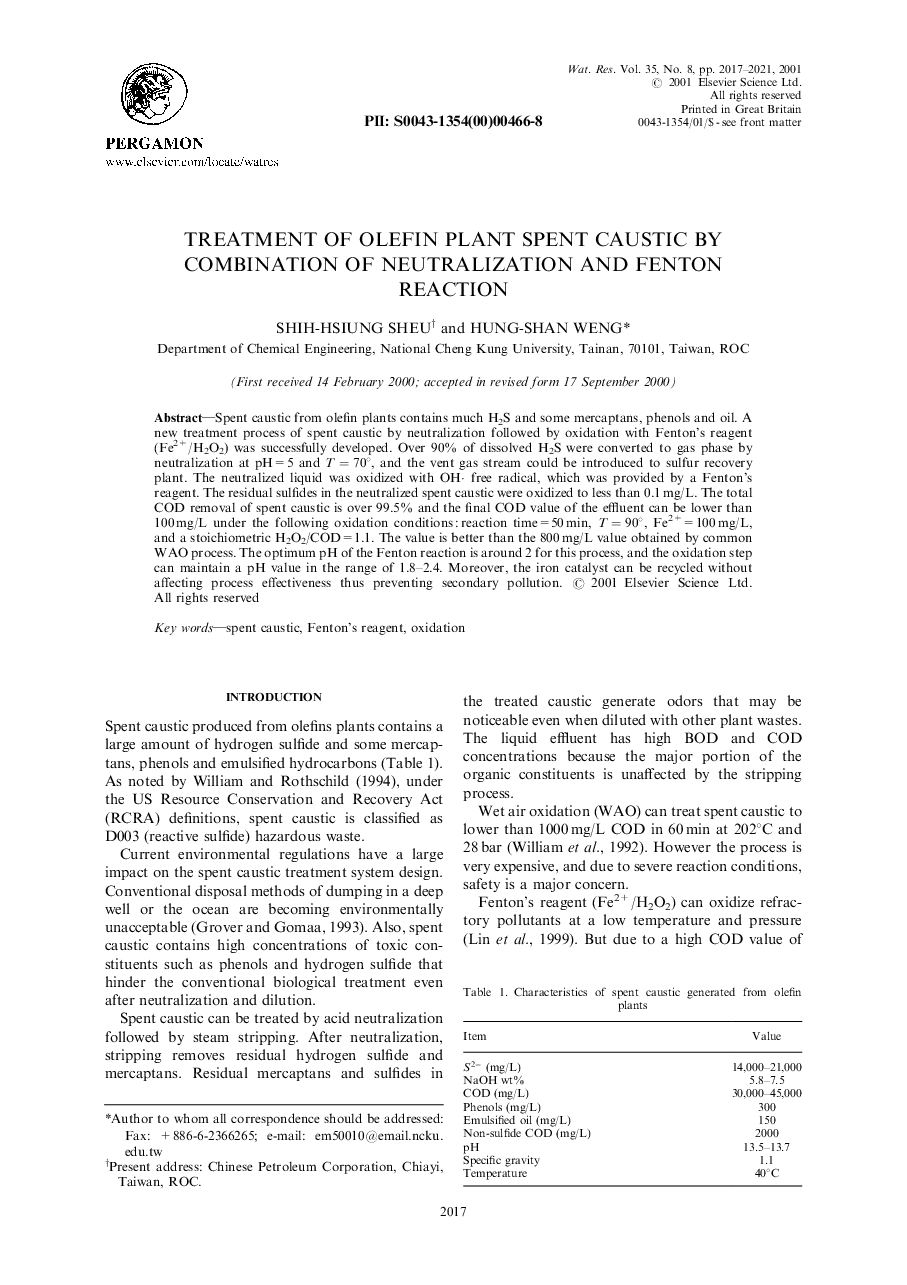

Spent caustic from olefin plants contains much H2S and some mercaptans, phenols and oil. A new treatment process of spent caustic by neutralization followed by oxidation with Fenton's reagent (Fe2+/H2O2) was successfully developed. Over 90% of dissolved H2S were converted to gas phase by neutralization at pH=5 and T=70°, and the vent gas stream could be introduced to sulfur recovery plant. The neutralized liquid was oxidized with OH· free radical, which was provided by a Fenton's reagent. The residual sulfides in the neutralized spent caustic were oxidized to less than 0.1 mg/L. The total COD removal of spent caustic is over 99.5% and the final COD value of the effluent can be lower than 100 mg/L under the following oxidation conditions : reaction time=50 min, T=90°, Fe2+=100 mg/L, and a stoichiometric H2O2/COD=1.1. The value is better than the 800 mg/L value obtained by common WAO process. The optimum pH of the Fenton reaction is around 2 for this process, and the oxidation step can maintain a pH value in the range of 1.8–2.4. Moreover, the iron catalyst can be recycled without affecting process effectiveness thus preventing secondary pollution.