| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4912596 | Construction and Building Materials | 2018 | 7 Pages |

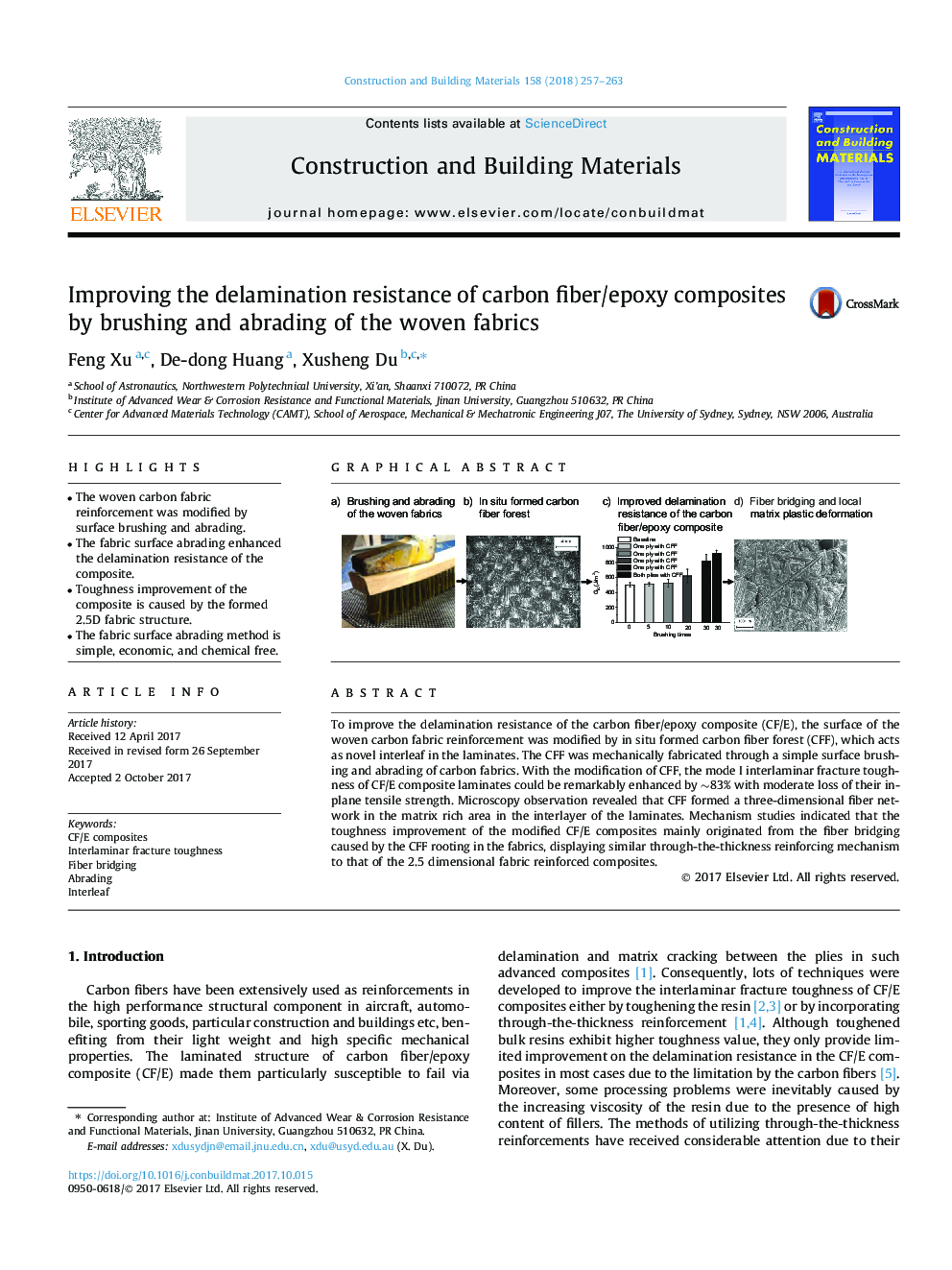

â¢The woven carbon fabric reinforcement was modified by surface brushing and abrading.â¢The fabric surface abrading enhanced the delamination resistance of the composite.â¢Toughness improvement of the composite is caused by the formed 2.5D fabric structure.â¢The fabric surface abrading method is simple, economic, and chemical free.

To improve the delamination resistance of the carbon fiber/epoxy composite (CF/E), the surface of the woven carbon fabric reinforcement was modified by in situ formed carbon fiber forest (CFF), which acts as novel interleaf in the laminates. The CFF was mechanically fabricated through a simple surface brushing and abrading of carbon fabrics. With the modification of CFF, the mode I interlaminar fracture toughness of CF/E composite laminates could be remarkably enhanced by â¼83% with moderate loss of their in-plane tensile strength. Microscopy observation revealed that CFF formed a three-dimensional fiber network in the matrix rich area in the interlayer of the laminates. Mechanism studies indicated that the toughness improvement of the modified CF/E composites mainly originated from the fiber bridging caused by the CFF rooting in the fabrics, displaying similar through-the-thickness reinforcing mechanism to that of the 2.5 dimensional fabric reinforced composites.

Graphical abstractDownload high-res image (267KB)Download full-size image