| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4979265 | Journal of Hazardous Materials | 2018 | 10 Pages |

â¢Electrostatic spray deposition (ESD) particle emissions are not well characterized.â¢Emission rates in sâ1 and μg sâ1 was defined for ESD of a photoactive nanocoating.â¢Particle deposition rates and morphologies of deposited particle were determined.â¢Emission rates and particle properties are required in exposure modellings.â¢Recommendations for ESD process exposure modellings is given.

Here, we studied the particle release rate during Electrostatic spray deposition of anatase-(TiO2)-based photoactive coating onto tiles and wallpaper using a commercially available electrostatic spray device. Spraying was performed in a 20.3 m3 test chamber while measuring concentrations of 5.6 nm to 31 μm-size particles and volatile organic compounds (VOC), as well as particle deposition onto room surfaces and on the spray gun user hand. The particle emission and deposition rates were quantified using aerosol mass balance modelling. The geometric mean particle number emission rate was 1.9 Ã 1010 sâ1 and the mean mass emission rate was 381 μg sâ1. The respirable mass emission-rate was 65% lower than observed for the entire measured size-range. The mass emission rates were linearly scalable (±ca. 20%) to the process duration. The particle deposition rates were up to 15 hâ1 for <1 μm-size and the deposited particles consisted of mainly TiO2, TiO2 mixed with Cl and/or Ag, TiO2 particles coated with carbon, and Ag particles with size ranging from 60 nm to ca. 5 μm. As expected, no significant VOC emissions were observed as a result of spraying. Finally, we provide recommendations for exposure model parameterization.

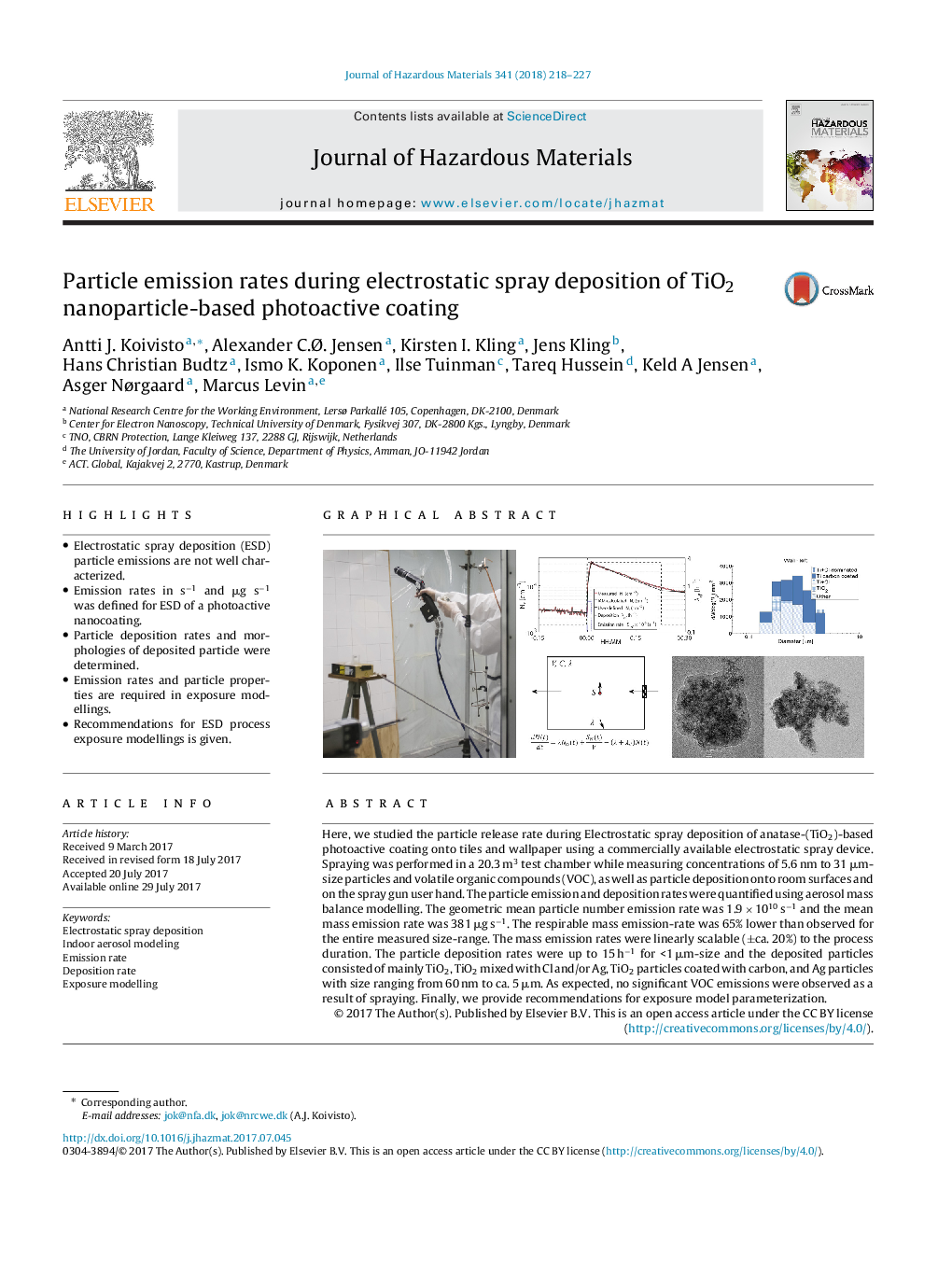

Graphical abstractDownload high-res image (353KB)Download full-size image