| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4979273 | Journal of Hazardous Materials | 2018 | 7 Pages |

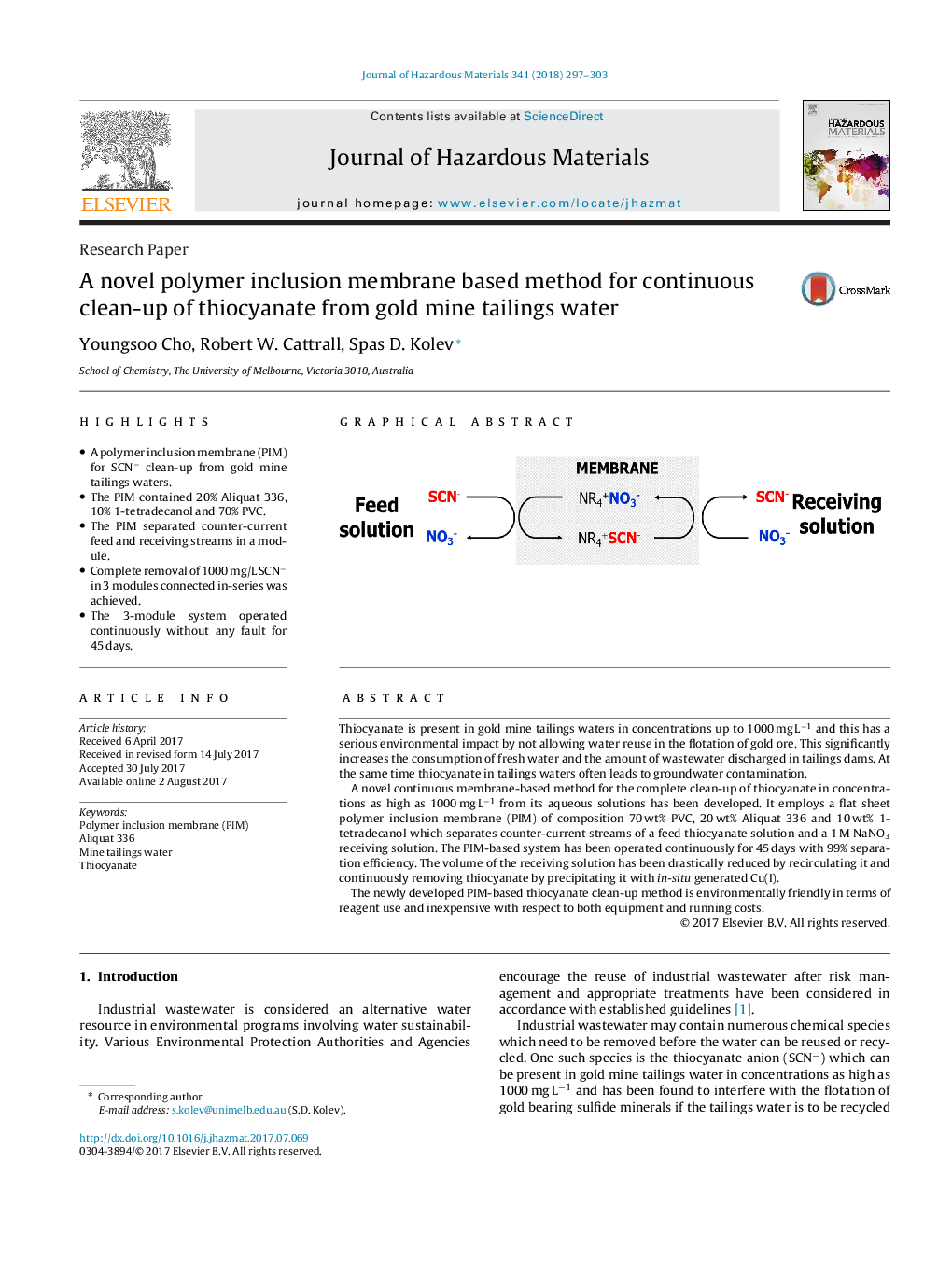

â¢A polymer inclusion membrane (PIM) for SCNâ clean-up from gold mine tailings waters.â¢The PIM contained 20% Aliquat 336, 10% 1-tetradecanol and 70% PVC.â¢The PIM separated counter-current feed and receiving streams in a module.â¢Complete removal of 1000 mg/L SCNâ in 3 modules connected in-series was achieved.â¢The 3-module system operated continuously without any fault for 45 days.

Thiocyanate is present in gold mine tailings waters in concentrations up to 1000 mg Lâ1 and this has a serious environmental impact by not allowing water reuse in the flotation of gold ore. This significantly increases the consumption of fresh water and the amount of wastewater discharged in tailings dams. At the same time thiocyanate in tailings waters often leads to groundwater contamination.A novel continuous membrane-based method for the complete clean-up of thiocyanate in concentrations as high as 1000 mg Lâ1 from its aqueous solutions has been developed. It employs a flat sheet polymer inclusion membrane (PIM) of composition 70 wt% PVC, 20 wt% Aliquat 336 and 10 wt% 1-tetradecanol which separates counter-current streams of a feed thiocyanate solution and a 1 M NaNO3 receiving solution. The PIM-based system has been operated continuously for 45 days with 99% separation efficiency. The volume of the receiving solution has been drastically reduced by recirculating it and continuously removing thiocyanate by precipitating it with in-situ generated Cu(I).The newly developed PIM-based thiocyanate clean-up method is environmentally friendly in terms of reagent use and inexpensive with respect to both equipment and running costs.

Graphical abstractDownload high-res image (159KB)Download full-size image