| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4996814 | Bioresource Technology | 2017 | 9 Pages |

â¢DryPB significantly reduces wastewater generation and energy consumption.â¢DryPB significantly reduces the MESP of cellulosic ethanol close to corn ethanol.â¢DryPB significantly elevates the commercial potential of cellulosic ethanol.â¢Technical and economical gap between cellulosic and corn ethanol is almost filled up.

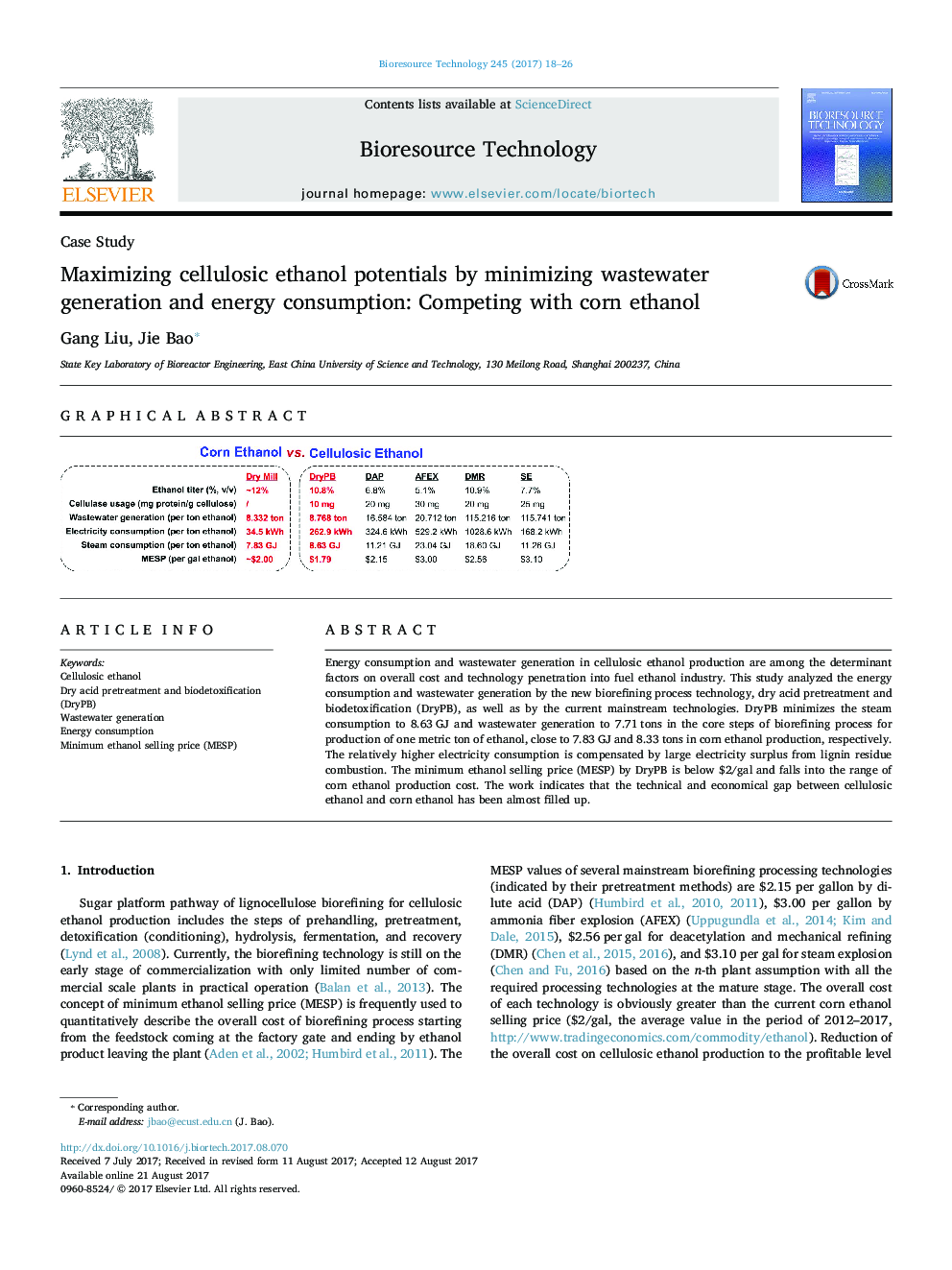

Energy consumption and wastewater generation in cellulosic ethanol production are among the determinant factors on overall cost and technology penetration into fuel ethanol industry. This study analyzed the energy consumption and wastewater generation by the new biorefining process technology, dry acid pretreatment and biodetoxification (DryPB), as well as by the current mainstream technologies. DryPB minimizes the steam consumption to 8.63Â GJ and wastewater generation to 7.71Â tons in the core steps of biorefining process for production of one metric ton of ethanol, close to 7.83Â GJ and 8.33Â tons in corn ethanol production, respectively. The relatively higher electricity consumption is compensated by large electricity surplus from lignin residue combustion. The minimum ethanol selling price (MESP) by DryPB is below $2/gal and falls into the range of corn ethanol production cost. The work indicates that the technical and economical gap between cellulosic ethanol and corn ethanol has been almost filled up.

Graphical abstractDownload high-res image (113KB)Download full-size image