| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4997337 | Bioresource Technology | 2017 | 10 Pages |

â¢Dilute alkali pretreatment enhanced the yield and economy of biofuel production.â¢Biogas was produced from hemicelluloses that were not fermentable by S. cerevisiae.â¢The maximum ethanol yield from the solid fraction of pretreated pinewood was 78%.â¢The maximum total energy of 6.29 GJ/ton can be generated from pretreated pinewood.â¢Biogas yield and the economic viability were reduced at higher NaOH concentration.

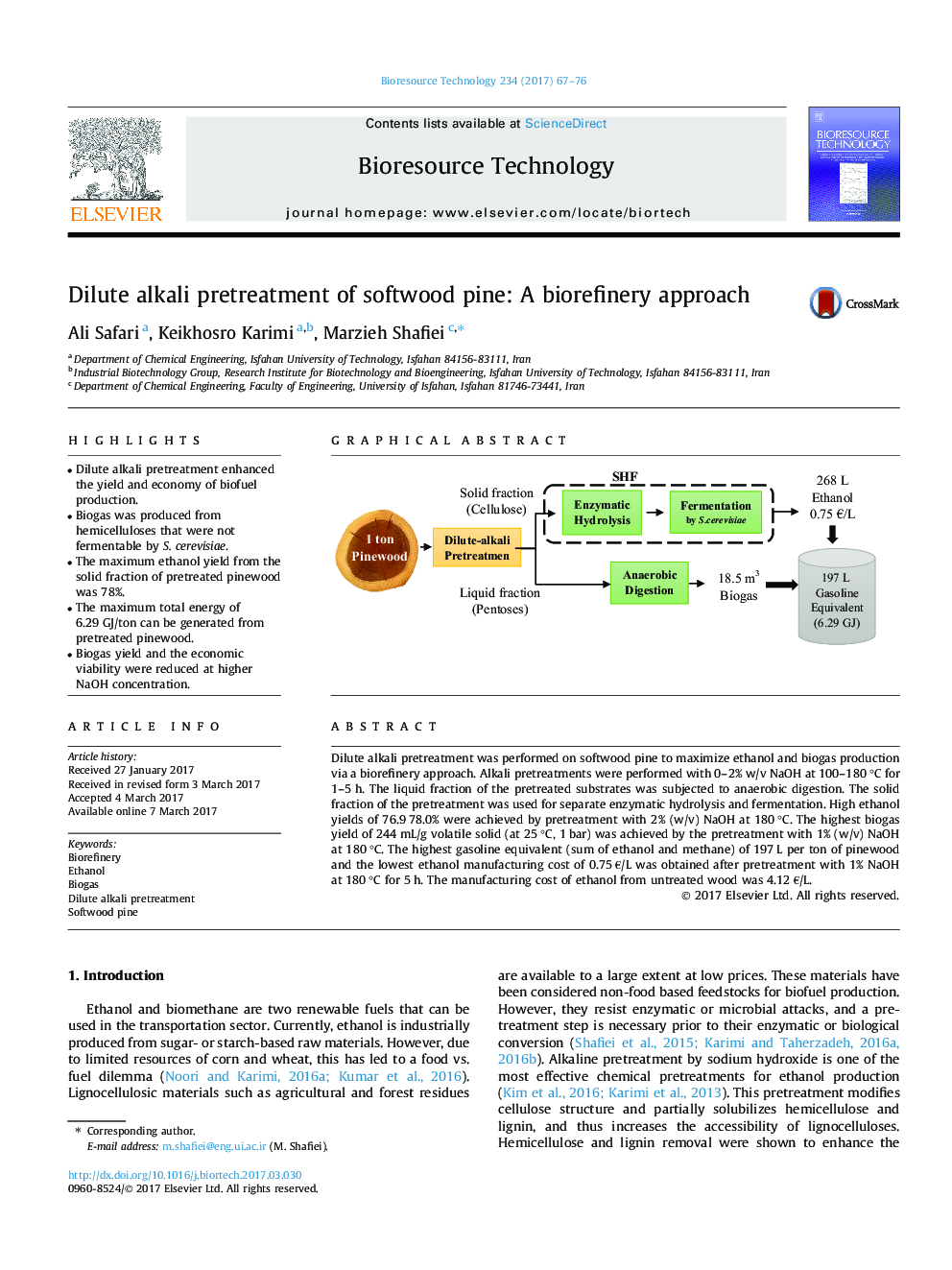

Dilute alkali pretreatment was performed on softwood pine to maximize ethanol and biogas production via a biorefinery approach. Alkali pretreatments were performed with 0-2% w/v NaOH at 100-180 °C for 1-5 h. The liquid fraction of the pretreated substrates was subjected to anaerobic digestion. The solid fraction of the pretreatment was used for separate enzymatic hydrolysis and fermentation. High ethanol yields of 76.9â78.0% were achieved by pretreatment with 2% (w/v) NaOH at 180 °C. The highest biogas yield of 244 mL/g volatile solid (at 25 °C, 1 bar) was achieved by the pretreatment with 1% (w/v) NaOH at 180 °C. The highest gasoline equivalent (sum of ethanol and methane) of 197 L per ton of pinewood and the lowest ethanol manufacturing cost of 0.75 â¬/L was obtained after pretreatment with 1% NaOH at 180 °C for 5 h. The manufacturing cost of ethanol from untreated wood was 4.12 â¬/L.

Graphical abstractDownload high-res image (161KB)Download full-size image