| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5002555 | IFAC-PapersOnLine | 2016 | 7 Pages |

Abstract

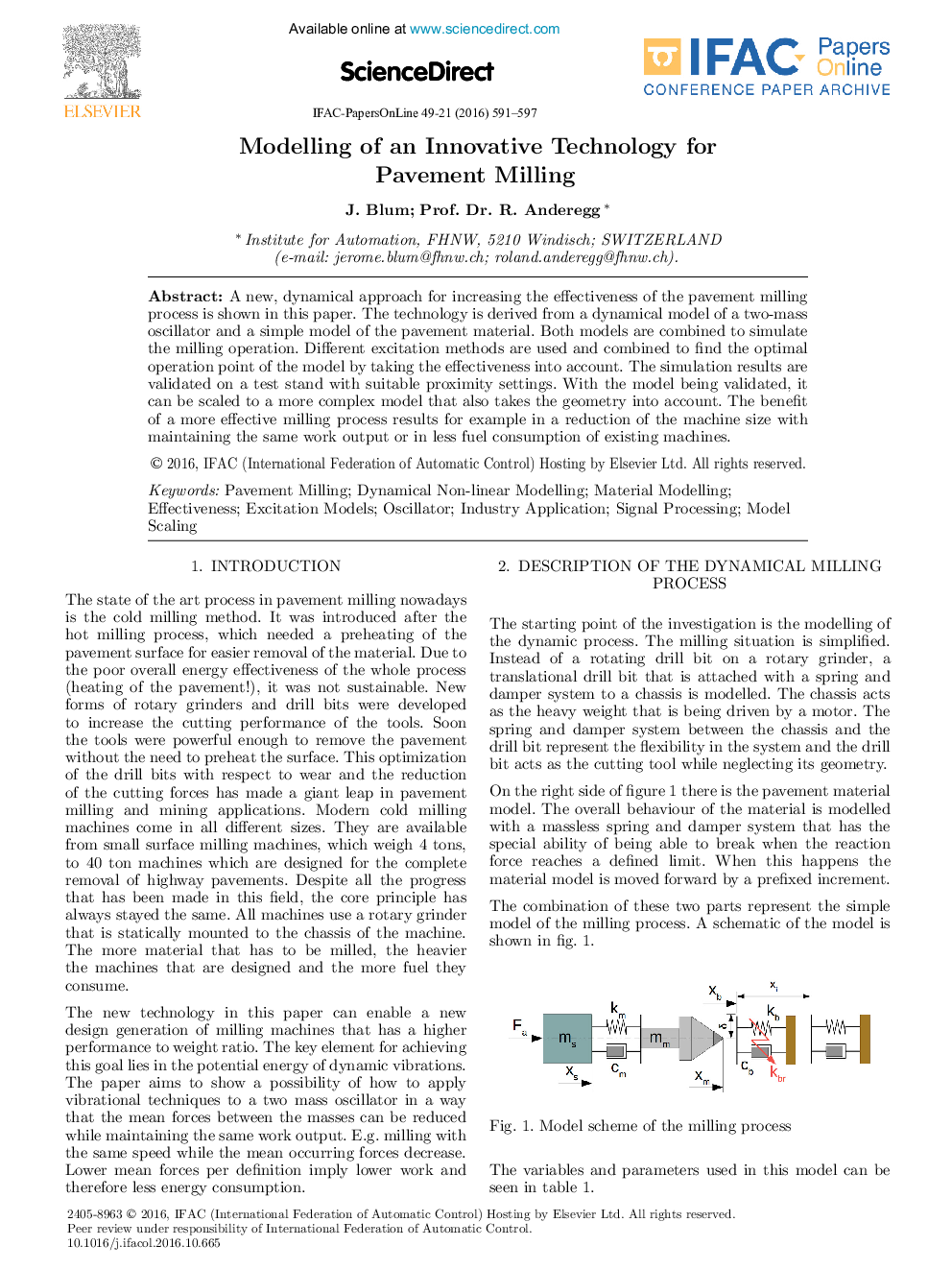

A new, dynamical approach for increasing the effectiveness of the pavement milling process is shown in this paper. The technology is derived from a dynamical model of a two-mass oscillator and a simple model of the pavement material. Both models are combined to simulate the milling operation. Different excitation methods are used and combined to find the optimal operation point of the model by taking the effectiveness into account. The simulation results are validated on a test stand with suitable proximity settings. With the model being validated, it can be scaled to a more complex model that also takes the geometry into account. The benefit of a more effective milling process results for example in a reduction of the machine size with maintaining the same work output or in less fuel consumption of existing machines.

Related Topics

Physical Sciences and Engineering

Engineering

Computational Mechanics

Authors

J. Blum, R. (Prof. Dr.),