| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 5003008 | IFAC-PapersOnLine | 2016 | 6 Pages |

Abstract

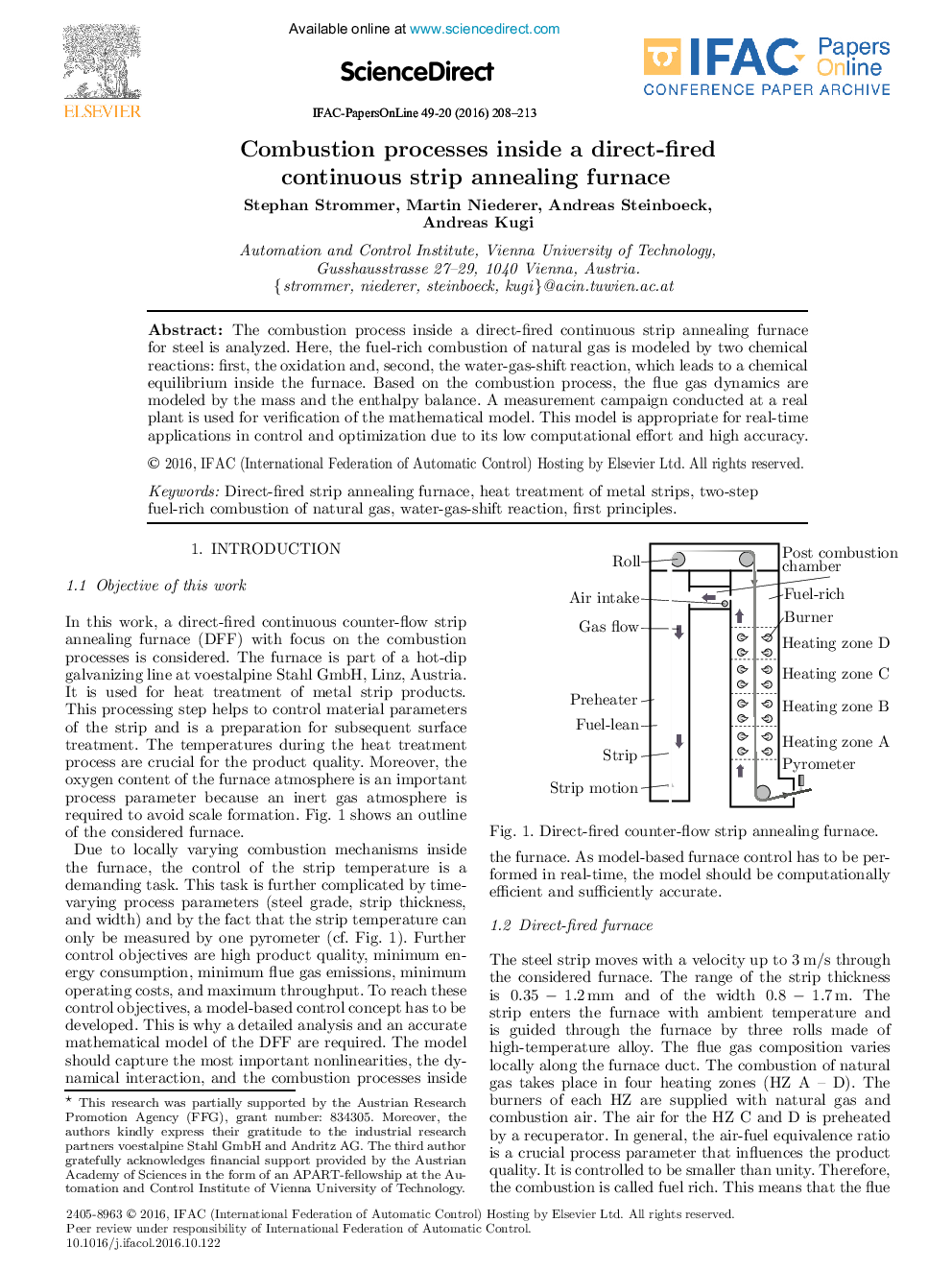

The combustion process inside a direct-fired continuous strip annealing furnace for steel is analyzed. Here, the fuel-rich combustion of natural gas is modeled by two chemical reactions: first, the oxidation and, second, the water-gas-shift reaction, which leads to a chemical equilibrium inside the furnace. Based on the combustion process, the flue gas dynamics are modeled by the mass and the enthalpy balance. A measurement campaign conducted at a real plant is used for verification of the mathematical model. This model is appropriate for real-time applications in control and optimization due to its low computational effort and high accuracy.

Related Topics

Physical Sciences and Engineering

Engineering

Computational Mechanics

Authors

Stephan Strommer, Martin Niederer, Andreas Steinboeck, Andreas Kugi,